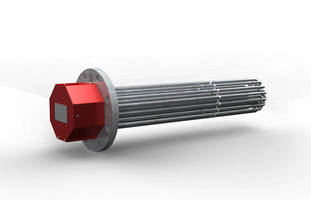

Immersion Heaters - Flange heater in the Spotlight

In industrial environments many types of fluids are stored and pumped from reservoirs and tanks. In order to protect some fluids from freezing and to keep the viscosity at the desired level, it is often necessary to heat these liquids and keep them at a specific temperature. When it comes to tank heating, flange heaters are some of the most efficient and cost effective products you can choose for process heating.

Immersion Heat

A flange heater works on the principle of immersion heat. An immersion heater is physically located inside or within the liquid it is heating. This is the most efficient way to heat fluids because all the heat from the unit is transferred into the liquid. In addition, this kind of immersion heater works fast.

Most companies are turning to immersion heat because of its efficiency and ease of installation. For example, oil heating is necessary in the petroleum industry for a wide range of processes, and flange immersion heaters can be used in just about all of them. These heaters are simple to maintain and this is another way that many businesses are saving money on maintenance costs.

Why Flange Heaters?

Flange heaters work on a simple principle. They contain tubular type heating elements connected to a flange. The heat elements are enclosed in a container known as a thermowell. In this way, immersion heating can be accomplished without subjecting the heating elements to the fluids or gases they are heating. This prevents corrosion and scale buildup, and many other problems that can occur in corrosive environments.