Gore Invests More into the Semiconductor Equipment Industry

Share:

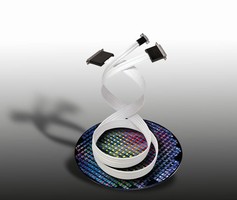

Elkton, MD (July 2008) - W. L. Gore & Associates (Gore) has now doubled its manufacturing capacity for flat cables to keep pace with customer demand for cables capable of reducing particles and outgassing in semiconductor manufacturing steps such as lithography, ion implantation, and inspection. The additional capacity includes the ability to make flat cables up to 300 mm wide so multiple cables can be replaced with a single, self-supporting cable perfect for stroke lengths of 500 mm or less.

Gore designs high flex cables that survive the extreme conditions found in clean room environments. These cables can be used in ISO14644-1 Class 3 (FS 209E Class 1) environments. The key to Gore's high flex and low particulation performance is its ePTFE composite jacket. This material has a low coefficient of friction and excellent tear resistance. It is also very flexible and enables flat cables to be stacked on top of each other and slide smoothly without generating particles. Alternative flat cable options use extruded jackets, such as silicone and polyurethane. These cables create particles as they wear because their coefficient of friction is much greater than Gore's ePTFE composite jacket.

Gore offers several high flex, clean (low particulation and outgassing) cable solutions including GORE(TM) High Flex Flat Cable, GORE(TM) Trackless Cable, and GORE(TM) High Flex Round Cable. GORE(TM) High Flex Flat Cable provides excellent cable management because they do not require cable dividers within cable track. This reduces particulation and results in extended cable life. GORE(TM) Trackless Cable eliminates the need for cable track and many of the problems associated with cable track, such as particulation, vibration, size, weight and noise. Additionally, a low particulation jacket is available for GORE(TM) High Flex Round Cable.

These cables are available on Gore's on-line design tool, where design engineers can choose from standard cable cores and components to design high flex cables and/or assemblies. The GORE(TM) High Flex Cable Configurator can be accessed at gore.com/designacable. Gore's on-line cable offerings include all of the components necessary to drive and control a motion system including shielded/unshielded power and signal, video, Ethernet, IEEE 1394, fiber optic and pneumatic lines.

For more information, contact W. L. Gore & Associates at 800-445-4673, 302-292-5100, or visit their Web site at gore.com.

About W. L. Gore & Associates

Perhaps best known for its consumer products like GORE-TEX® fabric and ELIXIR® guitar strings, Gore is a leading manufacturer of thousands of advanced technology products for the electronics, industrial, fabrics and medical markets. The company is headquartered in Newark, Delaware, USA, posts sales of almost $2.5 billion, and employs more than 8,000 associates at 45 facilities throughout the world. Gore is one of only three companies to appear on all of the U.S. "100 Best Companies to Work For" lists since the rankings were introduced in 1984, and has been named to a variety of European "Best Company" lists as well.

Please send leads to:

Technical Marketing Support

W. L. Gore & Associates, Inc.

402 Vieve's Way

Elkton, MD 21922

(800) 445-4673

Editorial contacts:

Jennifer C. Haupt

Marketing Communications

(410) 506-4569

jhaupt@wlgore.com

Bill Maurer

Macrovision, Inc.

(215) 348-1010

bill@macrovis.com