GF Piping Systems Introduces New Generation Cone Check Valve Series Featuring Improved Safety, Simplicity and Efficiency

Tustin, Calif. - GF Piping Systems has introduced the new generation Type 561/562 Cone Check Valve and the Type 591/595 Vent and Bleed Valve Series featuring a new spherical cone shape design that offers improved flow characteristics and leak-proof operating performance. Available in sizes from 3/8" - 4", customers can select from PVC, CPVC, PROGEF Standard, Polypropylene, SYGEF® PVDF, or ABS materials to match their plastic piping system. Sealing materials are available in EPDM and FPM.

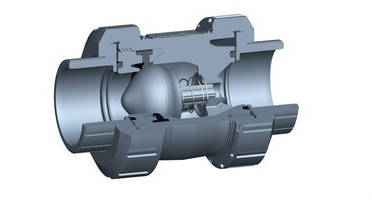

Type 561/562 Cone Check Valves

The Type 561 and Type 562 Cone Check Valves incorporate the latest in check valve technology to provide enhanced safety, simplified handling and increased efficiency. Several design elements are at the core of its higher performance operation. The valve's aerodynamic, spherical shaped cone ensures tight closing and 100 percent leak-proof operation. The cone's double bearing prevents it from tilting, even with rapid closing, and eliminates malfunctions. Additional benefits of the valve's spherical cone include improved Cv values over standard ball-type check valves and minimized cleaning and servicing due to the smallest possible contamination surface.

For maximum versatility, the Type 562 Valve version incorporates an integrated stainless steel spring (other material options available) for horizontal installation while maintaining its 100% leak tightness and operating pressure rating of 2.9 PSI. The Type 561 Valve (without spring) is mounted vertically and features 100% leak-tightness at a water column of six feet with 2.9 PSI.

The valves are self-closing by means of the existing pressure exerted by the medium. This eliminates the need for another energy source for opening or closing, offering improved operating efficiency. The valve's smooth transition and radii result in a higher flow rate (compared to conventional check valves) and less wear and tear, less pressure loss and reduced maintenance. Other design features include a cone guide that prevents jamming, a fixed gasket that eliminates slipping, bending or gasket erosion; and a union that allows for easy replacement or maintenance in the field. Customers can select from solvent cement socket, NPT thread, socket and IR fusion joining methods.

"The new generation check valve series' improved functionality combined with the expanded size range through 4 inches will be a great advantage to customers who want to optimize their piping systems with the most advanced technology possible," says Dave Vollaire, GF Piping Systems Product Manager, Valves and Actuation.

The Type 561/562 Cone Check Valves are suitable for back flow prevention in building systems and maintaining prime on pumps. They can also serve as a foot valve when used in conjunction with the GF Piping Systems' Type 050 Strainer. Industries include chemical processing, water treatment, microelectronics, food and beverage, cooling, and ship building.

Type 591/595 Bleed and Ventilating Valves

The Type 591 Bleed Valve and the 595 Ventilating Valve Series features an open air vent designed for containers or pipes that must be aerated and/or vented. These valves incorporate a float mechanism that opens the valve when the level of the liquid falls and closes the valve if the level of the liquid rises. The new ventilating and bleed valves are suitable for applications requiring de-aerating of air while filling piping systems and tanks, or to eliminate vacuums and discharge air pockets.

GF Piping Systems supplies a full range of plastic pipe, fittings, tubing, valves, actuators, rotameters, fusion machines, secondary containment, tank linings, heat exchangers, custom products, and sensors and instrumentation for industrial process control. For further information, contact GF Piping Systems, 2882 Dow Ave., Tustin, CA 92780-7258; Toll Free (800) 854-4090, Fax (714) 731-6923; e-mail: us.ps@georgfischer.com; Web: