BLM GROUP USA to Feature Tube Processing Technologies at Fabtech 2012

LT Fiber Laser and ELECT XL Tube Benders highlight exhibit along with EM80 end forming machining center, LT JUMBO Laser and Cold Saw equipment

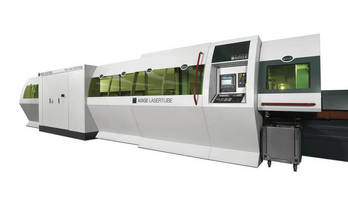

BLM GROUP USA (Wixom, MI), (www.blmgroup.com) a global leader in the manufacture of tube processing solutions will feature its wide array of equipment in booth C-1717 at FABTECH 2012, November 12-14, 2012, Las Vegas. Equipment to be shown include the company's LT Fiber Laser and ELECT XL Tube Bender machines.

Information will also be available on the company's LT JUMBO Series, an automatic laser tube cutting system designed to bring higher levels of precision to large diameter, thick walled tubes; the new EM80, an integrated CNC end machining center to cut, chamfer, face, bore, thread and profile tube; and the company's automatic tube saw lineup that provides an advanced tube cutting system to combines high productivity, accuracy, economical operation, and an exceptional degree of flexibility.

LT FIBER, is the first automated laser tube cutting machine to utilize a fiber laser resonator. Thanks to the versatility of its advanced 2 kW IPG fiber laser source, the system can efficiently process highly reflective materials such as brass, copper and aluminum. It also exhibits superior cutting characteristics with galvanized steel and has registered considerable productivity increases in the cutting of thin-walled tubes.

The fiber laser provides a dramatic improvement in energy efficiency when compared to the more traditional CO2 resonator leading to as much as a 50% reduction in the hourly operating cost. The system accommodates tube up to 6-inches (152 mm) diameter with maximum raw tube lengths of 256 to 335-inches (6500 to 8500 mm), depending on the configuration chosen.

The ELECT XL(TM) all-electric 12-axis tube bending machine brings new levels of productivity, flexibility and accuracy to the bending of large diameter (up to 150 mm/6 in.) tube, making it the ideal choice for many demanding automotive, machinery, motorcycle, hydraulic, railway and shipyard applications.

Flexibility and productivity are both enhanced by the fact that the system is a multi-stack bender capable of holding up to 8 tool sets permitting rapid processing of

complex parts and faster changeover, benefits not generally associated with the bending of large diameter tubes. Another key to ELECT XL's superior performance is VGP3D, its easy to use, yet advanced 3D graphical programming software.

LT JUMBO Series, an automatic laser tube cutting system designed to bring higher levels of precision to the laser cutting of large diameter, thick walled tubes, along with the heightened efficiency and productivity needed to compete with the plasma systems commonly used to cut this class of material.

The EM80 end machining center operates in several stages or stations. Parts are indexed by a three-position rotary transfer with each position providing a self-centering clamping jaw. The first cuts the tube or bar to length, the second for turning operations such as roughing and finishing and the third stage for boring, tapping or measuring with part washing between.

The automatic tube saw has been designed to operate either as a stand alone unit or as part of a fully automated tube processing line controlled by a single CNC, integrating all downstream functions such as deburring, washing, drying and accumulating.

BLM GROUP is a global leader in tube processing solutions. Its product line includes laser cutting, cold sawing, bending, end-forming, and tube measurement

equipment, as well as wire bending machines. With more than 50 years of tube experience and thousands of applications, the BLM GROUP is a leader in the manufacture of tube fabrication equipment.

BLM GROUP USA

29380 Beck Road, Wixom, MI 48393

Tel: 248.560.0080 o Fax: 248.560.0083

www.blmgroup.com

For further editorial information, contact:

Ed Szykula, Kracoe Szykula & Townsend

szykula@ksthip.com