Surftran

Madison Heights, MI 48071 1612

Share:

Single Station System offers part deburring and cleaning.

Model EC-20-1 combines Electrolytic Deburring/Edge Finishing/Contouring system and Aqueous Cleaning system. Both are modular and constructed with stainless steel and non-corrosive materials. In combination, systems provide accurate deburred, edge finished or contoured parts that are aqueous-cleaned and dried. Multiple fixtures are provided for load/unload parts handling. Finished parts can be of...

Read More »

Deburring/Deflashing System vaporizes metallic contaminants.

EURO-TEM P-400 Thermal Energy Method deburring/deflashing system, suited for metal-working industry, completely eliminates all burrs and flash, both internally and externally. Deburring/deflashing chamber is sealed with 400 tons of pressure during deburring/deflashing cycle. Unit has 5-station index table for loading and unloading, includes PLC control, and meets European CE specifications.

Read More »

Electrolytic System deburrs, finishes edges, and contours.

Model EC-20-1 (Electrolytic-Series 20-Single station) cationic system incorporates switching, compact, 1,000 A power supply capable of producing pulse current down to 20 msec on/off cycles and constant voltage/current. Fixture has multiple parts processing capability, allowing operators to use programmable control system with touchscreen MMI PLC/Interface and PLC based short circuit protection...

Read More »

Thermal System instantly vaporizes burrs and flash.

Large-capacity, 5-station EURO-TEM P-350 Thermal Energy Method system deburrs cast-iron, steel, stainless steel, brass, and aluminum parts, and deflashes zinc parts, completely eliminating burrs and flash internally and externally without parts wear, media or metallurgical change. Parts from 8 in. dia x 7 in. deep to 12.5 in. dia x 12 in. deep are accommodated. While parts are being...

Read More »

Deburring/Deflashing System rids parts of all contaminants.

EURO-TEM P-300 vaporizes all burrs, flash, and metallic contaminants. Zinc parts are deflashed without part wear, abrasion, media, or metallurgical change. Programmable control system's operator interface provides prompting, maintenance, and systems diagnostics. System has complete surround sound enclosure, exhaust system, and optional operator safety curtain. Options include automated...

Read More »

Aqueous Cleaning System features modular design.

STORM Aqueous Cleaning System measures 26 x 72 x 96 in. with stainless steel construction. Sealed single processing chamber accepts stainless steel parts holding basket and has load capacity of 350 lbs. Functions include wash, rinse, heated deionized water rinse, jet spray, immersed turbojet spray, and hot air drying with 750 cfm Paxton supercharger, which produces 40 kW of forced hot air...

Read More »

Deburring Machine works electrolytically.

ECD Electrolytic Deburring/Contouring machine generates shapes and intricate contouring. Workpiece receives positive charge from anode contacts mounted on upper moving part of fixture. Material is selectively removed from positively charged workpiece when electrolyte is flushed between it and negatively charged electrode. There is no direct contact between tool and workpiece, resulting in no...

Read More »TEM Systems remove every burr.

TEM (Thermal Energy Method) systems perform internal and external deburring of cast iron, steel, stainless steel, and aluminum parts with intense bursts of heat. They also perform deflashing of die cast zinc parts. Both manual and fully automatic TEM systems are available. Parts are sealed in deburring chamber by 250 ton force, and oxygen/natural gas mixture is introduced. Machine-initiated park...

Read More »

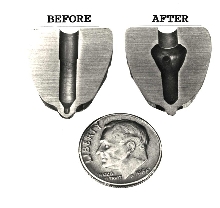

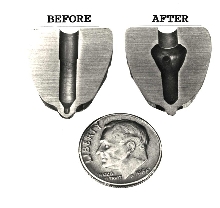

Deburring Machine cooks off defects.

Instant ConTEMporary Deburring machine can deburr, dewhisker and remove metallic contaminants from cast iron, steel, stainless steel and aluminum parts, and deflash zinc parts, all with burst of high heat. It completely removes burrs, even deep inside parts. In typical deburring cycle, parts are sealed in chamber. Mixture of oxygen and natural gas is introduced into chamber, ignited, and flash...

Read More »

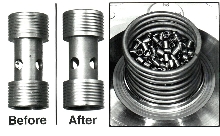

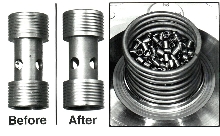

Deburring Machine burns off burrs with high heat.

Thermal Energy Method system vaporizes burrs, flash, and contaminants on hundreds of small parts internally and externally with bursts of high heat. It can deburr cast iron, steel, stainless steel, aluminum and brass, and deflash zinc parts. It works by loading parts into deburring chamber, where mixture of gas and oxygen is introduced, completely enveloping the parts. Spark ignites mixture,...

Read More »

Single Station System offers part deburring and cleaning.

Model EC-20-1 combines Electrolytic Deburring/Edge Finishing/Contouring system and Aqueous Cleaning system. Both are modular and constructed with stainless steel and non-corrosive materials. In combination, systems provide accurate deburred, edge finished or contoured parts that are aqueous-cleaned and dried. Multiple fixtures are provided for load/unload parts handling. Finished parts can be of...

Read More »

Deburring/Deflashing System vaporizes metallic contaminants.

EURO-TEM P-400 Thermal Energy Method deburring/deflashing system, suited for metal-working industry, completely eliminates all burrs and flash, both internally and externally. Deburring/deflashing chamber is sealed with 400 tons of pressure during deburring/deflashing cycle. Unit has 5-station index table for loading and unloading, includes PLC control, and meets European CE specifications.

Read More »

Electrolytic System deburrs, finishes edges, and contours.

Model EC-20-1 (Electrolytic-Series 20-Single station) cationic system incorporates switching, compact, 1,000 A power supply capable of producing pulse current down to 20 msec on/off cycles and constant voltage/current. Fixture has multiple parts processing capability, allowing operators to use programmable control system with touchscreen MMI PLC/Interface and PLC based short circuit protection...

Read More »

Thermal System instantly vaporizes burrs and flash.

Large-capacity, 5-station EURO-TEM P-350 Thermal Energy Method system deburrs cast-iron, steel, stainless steel, brass, and aluminum parts, and deflashes zinc parts, completely eliminating burrs and flash internally and externally without parts wear, media or metallurgical change. Parts from 8 in. dia x 7 in. deep to 12.5 in. dia x 12 in. deep are accommodated. While parts are being...

Read More »

Deburring/Deflashing System rids parts of all contaminants.

EURO-TEM P-300 vaporizes all burrs, flash, and metallic contaminants. Zinc parts are deflashed without part wear, abrasion, media, or metallurgical change. Programmable control system's operator interface provides prompting, maintenance, and systems diagnostics. System has complete surround sound enclosure, exhaust system, and optional operator safety curtain. Options include automated...

Read More »

Aqueous Cleaning System features modular design.

STORM Aqueous Cleaning System measures 26 x 72 x 96 in. with stainless steel construction. Sealed single processing chamber accepts stainless steel parts holding basket and has load capacity of 350 lbs. Functions include wash, rinse, heated deionized water rinse, jet spray, immersed turbojet spray, and hot air drying with 750 cfm Paxton supercharger, which produces 40 kW of forced hot air...

Read More »

Deburring Machine works electrolytically.

ECD Electrolytic Deburring/Contouring machine generates shapes and intricate contouring. Workpiece receives positive charge from anode contacts mounted on upper moving part of fixture. Material is selectively removed from positively charged workpiece when electrolyte is flushed between it and negatively charged electrode. There is no direct contact between tool and workpiece, resulting in no...

Read More »TEM Systems remove every burr.

TEM (Thermal Energy Method) systems perform internal and external deburring of cast iron, steel, stainless steel, and aluminum parts with intense bursts of heat. They also perform deflashing of die cast zinc parts. Both manual and fully automatic TEM systems are available. Parts are sealed in deburring chamber by 250 ton force, and oxygen/natural gas mixture is introduced. Machine-initiated park...

Read More »

Deburring Machine cooks off defects.

Instant ConTEMporary Deburring machine can deburr, dewhisker and remove metallic contaminants from cast iron, steel, stainless steel and aluminum parts, and deflash zinc parts, all with burst of high heat. It completely removes burrs, even deep inside parts. In typical deburring cycle, parts are sealed in chamber. Mixture of oxygen and natural gas is introduced into chamber, ignited, and flash...

Read More »

Deburring Machine burns off burrs with high heat.

Thermal Energy Method system vaporizes burrs, flash, and contaminants on hundreds of small parts internally and externally with bursts of high heat. It can deburr cast iron, steel, stainless steel, aluminum and brass, and deflash zinc parts. It works by loading parts into deburring chamber, where mixture of gas and oxygen is introduced, completely enveloping the parts. Spark ignites mixture,...

Read More »