LMC Workholding

P.O. Box 7006

Logansport, IN 46947-7006

Hydraulic Power Chuck suits hard turning applications.

Operating at speeds to 7,000 rpm, GHA6-8-66 consists of one 8 in., 3-jaw chuck with 66 mm through hole. Clamping repeatability is less than 10 microns. Additional offerings include proprietary and Matsumoto hydraulic power chucks, cylinders, and wheel chucks; rotary tables for single- and multiple-axis CNC machinery; Atling steady rests; and Neidlein face drivers. Unit permits machining at feed...

Read More »

Rotary Table delivers high speed and torque.

Model MDVVi 346 offers twin synchronized drives and split worm gear that deliver 200 rpm performance. Suitable for complex parts such as turbine blades or compressor scrolls, rotary table provides maximum machining force of 500 N-m with Ã-

Read More »

Rotary Tables suit multi-tasking machining centers.

MMK EDC 400 features direct-drive motor, zero-backlash positioning, and 5 arc-sec accuracy. It delivers speeds to 180 rpm and maximum torque of 694 N-m, for high-volume and aerospace production. MMK MDVVi 346 utilizes 2 synchronized servo motors that drive OTT worm gear. It delivers speeds to 200 rpm and torque of 500 N-m. Table suits rapid-response machining for complex parts manufacturing....

Read More »

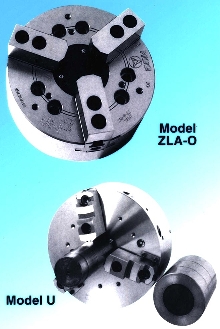

Power Chucks provide additional stroke travel.

Model ZLA-O and Model U solid center power chucks accept standard top jaws and feature hardened and ground keyways. Model ZLA-O is available in 3-jaw and 2-jaw configurations, operates up to 3000 rpm, and provides up to .92 in. jaw travel. Model U hydraulic actuated gear chuck grips different size workpieces without any change of top tooling. It delivers up to 4 in. jaw travel, and operates up to...

Read More »

Workpiece Support grips parts on lathe.

Atling Model LE, LZ and LA self-centering steady rests maintain integrity of shaft or bar workpieces that tend to bend or deflect under unstable cutting loads. It fits CNC or conventional lathes. Rest has three roller levers with machined curved surfaces that arc toward center of workpiece at 120Ã-

Read More »