LMC Workholding

P.O. Box 7006

Logansport, IN 46947-7006

Face Drivers provide tight tolerances.

Featuring heavy-duty components, Neidlein Face Drivers provide tight tolerances for hard turning, grinding, heavy cuts, and other special applications. Units allow entire OD of workpiece to be machined in single operation, eliminating changeovers. Virtually maintenance free, face drivers can allow for interrupted cuts, and turn small and large parts.

Read More »

Face Drivers enable gear hobbing in one operation.

Available in flange mount as well as morse-taper and straight shank, Series FDNC delivers concentricity/runout specifications of .00003-.00007. Center pin and drive disk system can be adjusted to achieve zero runout. Drive disks are available in clockwise, counterclockwise, and bi-directional versions. Using face driver allows entire workpiece to be exposed for machining and turned in one...

Read More »

Micro-Serrated Drive Pins enhance workholding capability.

Designed to facilitate hard turning, Neidlein hard-coated drive pins mount around face driver to reduce or eliminate part slippage and scrapped parts. If slippage occurs, pins can be used again. Given proper parameters, products achieve circular run outs of less than 0.002 mm in long production runs. They work with proprietary SB/FSB and FFB face drivers as well as special application face...

Read More »

Hydraulic Power Chuck operates at 7,000 rpm.

Featuring 66 mm thru hole, 8 in., 3-jaw Model GHA6-8-66 allows users to chuck large parts or bar feed large diameter bar. Clamping repeatability is less than 10 microns. Chuck permits machining at speeds and feeds required for cutting aluminum, and is suited for machining steel, especially in hard turning applications.

Read More »

Wheel Chuck suits premachining operations.

Series WDF Deflash/Degate Wheel Chuck removes flash and gating out of cast aluminum wheels when run on automated wheel lathe. Chucking diameters range from 15-24 in., and various wheel sizes can be handled by single chuck. Part quality is optimized by consistent heat treat operations and by eliminating flashing that can cause problems in painted wheels.

Read More »

Drive Pins reduce slippage in hard turning applications.

Micro-serrated, hard-coated Neidlein face driver drive pins reduce or eliminate part slippage, reduce scrapped parts, and increase turning productivity. If part slips, it will not remove serrations or coating, and pins can be used again. Products achieve circular run outs of less than 0.0007 in. in long production runs. Drive pins can be used with SB/FSB and FFB face drivers and all special...

Read More »

Chuck Exchange System provides fast changeovers.

With AJC Chucking System, face of chuck comes off as single unit so all 3 jaws can be removed and replaced simultaneously. Separate plate containing top jaws for each part can be stored on rack next to turning center. Auto-clamping feature allows complete changeovers in less than 30 sec. When integrated with robot loader and vision part-identification system, it provides 100% unattended operation.

Read More »

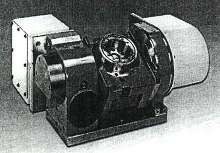

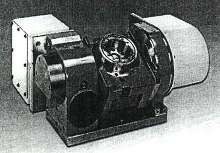

Rotary Table adds capability to vertical machining centers.

MDAT 2-axis NC Rotary Table adds 4th and 5th axes to 3-axis vertical machining centers by integrating directly into machine tool control. Stand-alone control is operated via M-codes and an RS-232C port connection. Slotted table face measures 3.94 in. dia and has 150Ã-

Read More »

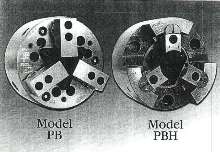

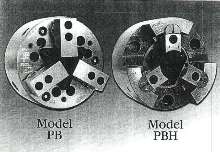

Pin Arbor Chucks machine flat, round parts.

Series LMC Models PB and PBH Pin Arbor Chucks eliminate distortion when holding round parts with flat surfaces. Both are offered with air, coolant, or both air and coolant supplied through chuck. They include pull-down and radial-clamping features and come in 5, 6, 8, and 10 in. sizes. Model PBH features standoff behind chuck to support back side of jaws. Chucks are typically used for machining...

Read More »

Compact NC Rotary Tables suit wire or RAM EDM machines.

Model MDHW and MDWAT 102B each hold and position workpieces in wirecut and sinker type EDM units. With stainless steel construction, each unit has environmental seals that allow unit to be completely submerged in dielectric fluid. Single-axis MDHW rotates 360Ã-

Read More »LMC Announces New VP of Machine Tool Dealers Sales

LMC Workholding is excited to announce the hiring of Mike Padilla as its new VP of Machine Tool Dealers Sales for North America. Mike is a long-time veteran of the US Navy (Where he received a combat action service ribbon and Purple Heart during Desert Storm) and the Machine Tool Industry. Mike’s previous roles include Regional Manager for SMW Systems (Also Known as ATS Systems), Accessory...

Read More »

Face Drivers provide tight tolerances.

Featuring heavy-duty components, Neidlein Face Drivers provide tight tolerances for hard turning, grinding, heavy cuts, and other special applications. Units allow entire OD of workpiece to be machined in single operation, eliminating changeovers. Virtually maintenance free, face drivers can allow for interrupted cuts, and turn small and large parts.

Read More »

Face Drivers enable gear hobbing in one operation.

Available in flange mount as well as morse-taper and straight shank, Series FDNC delivers concentricity/runout specifications of .00003-.00007. Center pin and drive disk system can be adjusted to achieve zero runout. Drive disks are available in clockwise, counterclockwise, and bi-directional versions. Using face driver allows entire workpiece to be exposed for machining and turned in one...

Read More »

Micro-Serrated Drive Pins enhance workholding capability.

Designed to facilitate hard turning, Neidlein hard-coated drive pins mount around face driver to reduce or eliminate part slippage and scrapped parts. If slippage occurs, pins can be used again. Given proper parameters, products achieve circular run outs of less than 0.002 mm in long production runs. They work with proprietary SB/FSB and FFB face drivers as well as special application face...

Read More »

Hydraulic Power Chuck operates at 7,000 rpm.

Featuring 66 mm thru hole, 8 in., 3-jaw Model GHA6-8-66 allows users to chuck large parts or bar feed large diameter bar. Clamping repeatability is less than 10 microns. Chuck permits machining at speeds and feeds required for cutting aluminum, and is suited for machining steel, especially in hard turning applications.

Read More »

Wheel Chuck suits premachining operations.

Series WDF Deflash/Degate Wheel Chuck removes flash and gating out of cast aluminum wheels when run on automated wheel lathe. Chucking diameters range from 15-24 in., and various wheel sizes can be handled by single chuck. Part quality is optimized by consistent heat treat operations and by eliminating flashing that can cause problems in painted wheels.

Read More »

Drive Pins reduce slippage in hard turning applications.

Micro-serrated, hard-coated Neidlein face driver drive pins reduce or eliminate part slippage, reduce scrapped parts, and increase turning productivity. If part slips, it will not remove serrations or coating, and pins can be used again. Products achieve circular run outs of less than 0.0007 in. in long production runs. Drive pins can be used with SB/FSB and FFB face drivers and all special...

Read More »

Chuck Exchange System provides fast changeovers.

With AJC Chucking System, face of chuck comes off as single unit so all 3 jaws can be removed and replaced simultaneously. Separate plate containing top jaws for each part can be stored on rack next to turning center. Auto-clamping feature allows complete changeovers in less than 30 sec. When integrated with robot loader and vision part-identification system, it provides 100% unattended operation.

Read More »

Rotary Table adds capability to vertical machining centers.

MDAT 2-axis NC Rotary Table adds 4th and 5th axes to 3-axis vertical machining centers by integrating directly into machine tool control. Stand-alone control is operated via M-codes and an RS-232C port connection. Slotted table face measures 3.94 in. dia and has 150Ã-

Read More »

Pin Arbor Chucks machine flat, round parts.

Series LMC Models PB and PBH Pin Arbor Chucks eliminate distortion when holding round parts with flat surfaces. Both are offered with air, coolant, or both air and coolant supplied through chuck. They include pull-down and radial-clamping features and come in 5, 6, 8, and 10 in. sizes. Model PBH features standoff behind chuck to support back side of jaws. Chucks are typically used for machining...

Read More »