Intech Power-Core

Closter, NJ 07624

Aggressive Solvent Meets Its Match

Closter, NJ: Roller swelling, erosion, deformation and premature equipment failure resulting from the hot, boiling solvent vapor used in Forward Technology's F-100 Series Compact Solvent Cleaning System set the manufacturer to search for an extended-wear roller material to withstand the automated vapor degreaser cleaning cycles for cleaning small precision components used in medical devices,...

Read More »

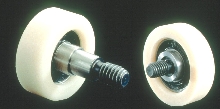

Rollers and Cam Followers offer alternative to metal rollers.

Self-Lubricating Power-Core curved, U- and V-shaped rollers will not wear out rail, and achieve noise reduction of 6-10 dBa over metal rollers. Precision machining provides minimal run-out, while tire material absorbs shock to provide smooth rolling motion and is resistant to chemicals and corrosion. Power-Core rollers operate in temperatures ranging from -60 to +140-°F and are suitable for...

Read More »

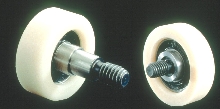

Composite Roller exhibits low rolling resistance.

Non-hygroscopic Power-Core roller, with integral roller bearing, runs quietly and absorbs vibration and shock without placing undue wear on rail. Snap-in design ensures snug bearing fit, and composite material features integral elasticity that provides structural resistance to developing flats under static loads. Roller retains dimension and tight bearing fit in all weather conditions. Roller to...

Read More »

Rollers offer non-lubricated performance.

Power-Core(TM) rollers feature crystalline structure that is resistant to flow under static load and does not absorb moisture. Rollers and cam followers retain bearing fit from -40Ã-

Read More »

Hybrid Gears solve noise and premature failure issues.

Power-Core(TM) Gears feature crystalline, non-hygroscopic, composite material that is gravity-cast around metal core. Gear teeth are hobbed into outer plastic portion of gear material. Bore machined into metal core secures temperature-resistant, metal-to-metal shaft connection. Metal core helps restrain thermal expansion of plastic portion of gear. It comes in carbon steel, stainless steel, or...

Read More »

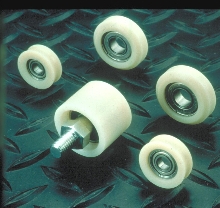

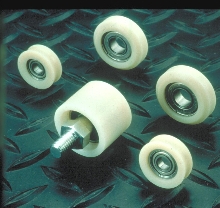

Composite Wheels operate in clean rooms.

Power-Core wheels eliminate possibility of metal particulate contamination in clean room operations. Composite wheel is comprised of two components: machined plastic tire and roller bearing. Tire material has high resistance to flow under load and retains tensile and flexural strength as well as dimensions in shock load applications. Bearings use clean room approved grease. Wheels eliminate need...

Read More »

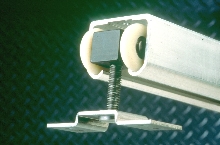

Roller makes it easy to open and close doors.

Power-Core(TM) roller and trolley system is suitable for precision sliding doors and indoor/outdoor architectural partitions. Roller is assembled using thermotechnology, rather than injection molding, and is combined with precision roller bearing to provide quiet and smooth ride. It resists flat development, will not absorb moisture, does not wear out rail, carries high loads and retains strength...

Read More »

Composite Rollers replace steel cam followers.

Quiet-running, self-lubricating Power-Core rollers work in demanding, load-bearing applications where noise, moisture, shock, temperature and rail wear present challenging operating environment. Roller includes long-wearing composite tire with stress-free crystalline structure that resists flattening from compression under static loads. Deformation resistance and internal elasticity provide...

Read More »

Rollers are custom made for each application.

Power-Core rollers have composite tires installed over roller or needle bearings. Rollers are custom manufactured to meet specs derived by engineering analysis of load data. Calculations include Hertzian stress and linear speed that enable engineers to make design recommendations. Applications include clean room conveyors, linear positioners, sliding door hardware and automatic doors for motor...

Read More »Aggressive Solvent Meets Its Match

Closter, NJ: Roller swelling, erosion, deformation and premature equipment failure resulting from the hot, boiling solvent vapor used in Forward Technology's F-100 Series Compact Solvent Cleaning System set the manufacturer to search for an extended-wear roller material to withstand the automated vapor degreaser cleaning cycles for cleaning small precision components used in medical devices,...

Read More »

Rollers and Cam Followers offer alternative to metal rollers.

Self-Lubricating Power-Core curved, U- and V-shaped rollers will not wear out rail, and achieve noise reduction of 6-10 dBa over metal rollers. Precision machining provides minimal run-out, while tire material absorbs shock to provide smooth rolling motion and is resistant to chemicals and corrosion. Power-Core rollers operate in temperatures ranging from -60 to +140-°F and are suitable for...

Read More »

Composite Roller exhibits low rolling resistance.

Non-hygroscopic Power-Core roller, with integral roller bearing, runs quietly and absorbs vibration and shock without placing undue wear on rail. Snap-in design ensures snug bearing fit, and composite material features integral elasticity that provides structural resistance to developing flats under static loads. Roller retains dimension and tight bearing fit in all weather conditions. Roller to...

Read More »

Rollers offer non-lubricated performance.

Power-Core(TM) rollers feature crystalline structure that is resistant to flow under static load and does not absorb moisture. Rollers and cam followers retain bearing fit from -40Ã-

Read More »

Hybrid Gears solve noise and premature failure issues.

Power-Core(TM) Gears feature crystalline, non-hygroscopic, composite material that is gravity-cast around metal core. Gear teeth are hobbed into outer plastic portion of gear material. Bore machined into metal core secures temperature-resistant, metal-to-metal shaft connection. Metal core helps restrain thermal expansion of plastic portion of gear. It comes in carbon steel, stainless steel, or...

Read More »

Composite Wheels operate in clean rooms.

Power-Core wheels eliminate possibility of metal particulate contamination in clean room operations. Composite wheel is comprised of two components: machined plastic tire and roller bearing. Tire material has high resistance to flow under load and retains tensile and flexural strength as well as dimensions in shock load applications. Bearings use clean room approved grease. Wheels eliminate need...

Read More »

Roller makes it easy to open and close doors.

Power-Core(TM) roller and trolley system is suitable for precision sliding doors and indoor/outdoor architectural partitions. Roller is assembled using thermotechnology, rather than injection molding, and is combined with precision roller bearing to provide quiet and smooth ride. It resists flat development, will not absorb moisture, does not wear out rail, carries high loads and retains strength...

Read More »

Composite Rollers replace steel cam followers.

Quiet-running, self-lubricating Power-Core rollers work in demanding, load-bearing applications where noise, moisture, shock, temperature and rail wear present challenging operating environment. Roller includes long-wearing composite tire with stress-free crystalline structure that resists flattening from compression under static loads. Deformation resistance and internal elasticity provide...

Read More »

Rollers are custom made for each application.

Power-Core rollers have composite tires installed over roller or needle bearings. Rollers are custom manufactured to meet specs derived by engineering analysis of load data. Calculations include Hertzian stress and linear speed that enable engineers to make design recommendations. Applications include clean room conveyors, linear positioners, sliding door hardware and automatic doors for motor...

Read More »