De Dietrich Process Systems, Inc.

Mountainside, NJ 07092

Share:

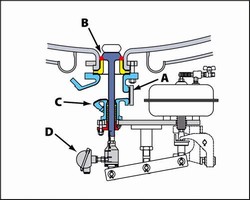

Flush Valve is suited for glass-lined reactors.

Glass-lined C.I.P. flush valve features flush port for sanitizing, sampling, and back flushing of tank without dismantling valve. Valve offers operating temperatures of -20 to +450Ã-

Read More »

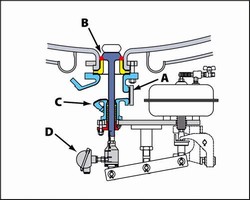

Flush Valve is suited for glass-lined reactors.

Glass-lined C.I.P. flush valve features flush port for sanitizing, sampling, and back flushing of tank without dismantling valve. Valve offers operating temperatures of -20 to +450Ã-

Read More »