Progressive - Ruesch Machine Co. Inc.

Ringwood, NJ 07456

Share:

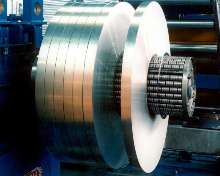

Core Slip Rewinding System provides constant coil tension.

Slip Tech system consists of core winding surface made entirely of bearings, which reduce friction between core surface and winding drum. This eliminates excess tension in individual rewound coils during build up, resulting in ability to maintain consistent coil tension because each strip is independently tensioned from core to finished coil OD. Product can also eliminate need for looping pits in...

Read More »

Wire Pay-Out is suited for traverse wound reels.

Suited for payout of traverse wound wire and strip from up to 1,250 lb reels, Model 605 Rim Drive maintains consistent line height and permits flexibility in stock orientation by allowing material to be paid out from top or the bottom of reel. Unit offers choice of 3 speed and tension control devices, each of which automatically monitor and compensate for payout reel's decreasing diameter while...

Read More »

Multi-Spindle Winder offer max line speed of 500 fpm.

Modular Model MS 104 runs either independently or series-coupled with other modules to control entire take-up line. Each module contains 20 moving parts, and all components are accessible from front or rear of unit. With standard tension of 8-32 oz, winder handles packages weighing up to 80 lb and measuring up to 18 in. diameter and 12 in. wide. Adjustable traverse assembly and lay on roller...

Read More »

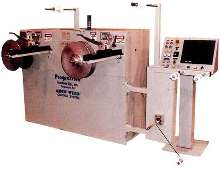

Computerized Camless Coiler offers max speed of 300 fpm.

By entering selected pattern via touchscreen interface, Model 298 produces single pancake, multi-layer, and helical coils. It features 3 driven, single-groove tooling rolls, one of which is a variable position bending roll for shaping coil. Finished coils are deposited onto receiving table, which can then be off-loaded by operator. Unit produces coils with minimum ID of 16 in., maximum OD of 51...

Read More »

Winding System winds ferrous and non-ferrous metal strip.

Model 620 features oscillating spindle that allows material to remain in fixed position while spool moves back and forth. Accurate traverse and pitch control from 1/8 to 1Ã-½ in. minimizes camber and results in solid, damage-free wind build. System is suited for secondary operations such as single strand rewind lines or converting pancake coils into traverse wound stock, as well as level...

Read More »

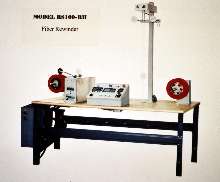

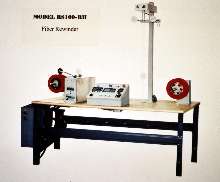

Winding System handles fine, delicate materials.

Featuring both spooler and pay off, table top Model RS100 can be operated from standing or sitting position. Control panel offers digital entry of winding parameters such as package width and material length. Stepper motor provides pitch control with digital readout in .0001 in. or 2.5 micron increments. Speed and tension are managed ultrasonically with non-contact loop detector. By regulating DC...

Read More »

Payout is suited traverse-wound reels.

Model 605 Rim Drive is suited for payout of traverse wound wire and strip from reels weighing up to 1,250 lb. Product maintains consistent line height and permits flexibility in stock orientation by allowing material to be paid out from top or bottom of reel. Choice of speed and tension control devices includes dancer system, articulated dancer system, and TELESENSOR, which eliminates back...

Read More »

Spring Core Chuck allows fast core changes without tools.

Spring Core Adapter mounts directly to shaft of Pay-Off or Take-Up machine. Pre-drilled holes permit springs to be located for either clockwise or counter clockwise slip, or no slip. Bowed spring design offers self-cleaning feature with each core removal. There are no grooves, clamps, or mechanical mechanisms where build up of core dust can reduce gripping action. Standard Core Adapters are...

Read More »

Oscillate Winding System offers up to 12 stations.

Model 630 PMC winds ferrous and non-ferrous metal strips directly from slitter and can be used in heavy-duty rewind applications. Individual winding stations, coordinated through Accu-Wind computer control system, offer cantilevered shafts for supporting spools or cores weighing up to 3,500 lbs. Each is equipped with 10 hp, 4-quadrant regenerative drive, capable of providing 150 lb material...

Read More »

Winder incorporates Accu-Wind control system.

Model MS 103-LD PMC, with dual spindle design, winds continuous lengths of difficult profile products. Both spindles operate through common dancer system to minimize change-over from full to empty spool. Accu-Wind manages machine functions/winding patterns, insuring precise placement of successive layers while maintaining tension and pitch controls. Line speed is rated to 500 FPM, package width...

Read More »Progressive-Ruesch Machine Company Recently Launched Their New Website

Progressive-Ruesch Machine Company located in Ringwood NJ recently launched their new website at www.progressivewinders.com Here you can see their many manufacturing capabilities for Custom Winders, Coilers, Slitters and Tube Equipment. Progressive-Ruesch Machine Company LLC., specializing in the design, engineering and manufacturing of durable; oscillate / traverse winding equipment can be found...

Read More »

Core Slip Rewinding System provides constant coil tension.

Slip Tech system consists of core winding surface made entirely of bearings, which reduce friction between core surface and winding drum. This eliminates excess tension in individual rewound coils during build up, resulting in ability to maintain consistent coil tension because each strip is independently tensioned from core to finished coil OD. Product can also eliminate need for looping pits in...

Read More »

Wire Pay-Out is suited for traverse wound reels.

Suited for payout of traverse wound wire and strip from up to 1,250 lb reels, Model 605 Rim Drive maintains consistent line height and permits flexibility in stock orientation by allowing material to be paid out from top or the bottom of reel. Unit offers choice of 3 speed and tension control devices, each of which automatically monitor and compensate for payout reel's decreasing diameter while...

Read More »

Multi-Spindle Winder offer max line speed of 500 fpm.

Modular Model MS 104 runs either independently or series-coupled with other modules to control entire take-up line. Each module contains 20 moving parts, and all components are accessible from front or rear of unit. With standard tension of 8-32 oz, winder handles packages weighing up to 80 lb and measuring up to 18 in. diameter and 12 in. wide. Adjustable traverse assembly and lay on roller...

Read More »

Computerized Camless Coiler offers max speed of 300 fpm.

By entering selected pattern via touchscreen interface, Model 298 produces single pancake, multi-layer, and helical coils. It features 3 driven, single-groove tooling rolls, one of which is a variable position bending roll for shaping coil. Finished coils are deposited onto receiving table, which can then be off-loaded by operator. Unit produces coils with minimum ID of 16 in., maximum OD of 51...

Read More »

Winding System winds ferrous and non-ferrous metal strip.

Model 620 features oscillating spindle that allows material to remain in fixed position while spool moves back and forth. Accurate traverse and pitch control from 1/8 to 1Ã-½ in. minimizes camber and results in solid, damage-free wind build. System is suited for secondary operations such as single strand rewind lines or converting pancake coils into traverse wound stock, as well as level...

Read More »

Winding System handles fine, delicate materials.

Featuring both spooler and pay off, table top Model RS100 can be operated from standing or sitting position. Control panel offers digital entry of winding parameters such as package width and material length. Stepper motor provides pitch control with digital readout in .0001 in. or 2.5 micron increments. Speed and tension are managed ultrasonically with non-contact loop detector. By regulating DC...

Read More »

Payout is suited traverse-wound reels.

Model 605 Rim Drive is suited for payout of traverse wound wire and strip from reels weighing up to 1,250 lb. Product maintains consistent line height and permits flexibility in stock orientation by allowing material to be paid out from top or bottom of reel. Choice of speed and tension control devices includes dancer system, articulated dancer system, and TELESENSOR, which eliminates back...

Read More »

Spring Core Chuck allows fast core changes without tools.

Spring Core Adapter mounts directly to shaft of Pay-Off or Take-Up machine. Pre-drilled holes permit springs to be located for either clockwise or counter clockwise slip, or no slip. Bowed spring design offers self-cleaning feature with each core removal. There are no grooves, clamps, or mechanical mechanisms where build up of core dust can reduce gripping action. Standard Core Adapters are...

Read More »

Oscillate Winding System offers up to 12 stations.

Model 630 PMC winds ferrous and non-ferrous metal strips directly from slitter and can be used in heavy-duty rewind applications. Individual winding stations, coordinated through Accu-Wind computer control system, offer cantilevered shafts for supporting spools or cores weighing up to 3,500 lbs. Each is equipped with 10 hp, 4-quadrant regenerative drive, capable of providing 150 lb material...

Read More »