Royal Machine & Tool Corp.

Berlin, CT 06037

Share:

Collet Chuck grabs and holds cast valve bodies.

With its 12 in. diameter, Double Collet Chuck grips flanged ends of 1/2 through 2 in. investment cast valve bodies. It can be adapted to lathes requiring single draw bar or draw tube operation, and can hold working parts having same or different locating diameters several inches apart. Draw-back function provides positive end location. Chuck is available in different sizes, and is made of...

Read More »

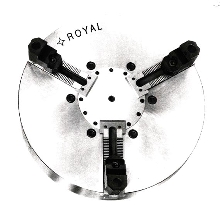

Power Chucks keep jaw force at maximum speeds.

Royal LS-HS Series three-jaw, wedge-type chucks maintain 80% of jaw force at high speeds, permitting turning of large dia work parts or frail work parts requiring light clamping force to prevent distortion. Chucks are made from high-alloy steel. They are available in 24-36 in. sizes with all standard master jaw configurations. Chip and coolant protection reduces lubrication frequency, increases...

Read More »