Weber Packaging Solutions

Arlington Heights, IL 60005

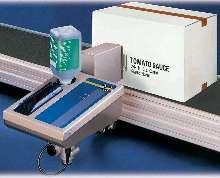

Inkjet Coder marks in-line products and packages.

Multiline ink jet coding system, configured with choice of 3 printheads, produces readable bar codes, text, and graphics in heights of 0.5, 0.9, or 1.9 in. Unit offers print speeds up to 325 fpm with various settings up to 300 dpi. Users enter code formats via integrated keyboard or by networking system to PC. Built for industrial environments, compact printhead is made of stainless steel, and...

Read More »

Wax Coding System works with non-porous surfaces.

Waxmark codes using one wax block that is warmed in reservoir until liquid enough to flow to printhead. Suited for in-line, automatic coding of non-porous surfaces, product prints 1-4 lines of high-resolution text and graphics up to 0.5 in. high. Speeds can reach up to 325 fpm, dependant on print height and density. Information may be entered into unit via integrated keyboard, which holds up to...

Read More »

Label Printer-Applicator applies labels to boxes on conveyors.

Model 5200 comes with choice of high-density thermal/thermal-transfer print engines that produce labels with text, bar codes, and graphics. Each engine is available in 203- or 300-dpi models, accommodates pressure-sensitive labels up to 6 in. wide by 6 in. long, and has print speeds up to 12 in. per sec. Model 5200 offers 3 label placement methods: air-blow, flex-tamp, and tamp-blow, all of which...

Read More »

Printer/Applicator labels top, bottom, or sides of product.

Model 5200 comes with 203 or 300 dpi printer and choice of 3 application methods: air blow, flex-tamp, or tamp-blow. All methods provide precise label placement of Ã-

Read More »

Thermal Printers produce bar codes, text and graphics.

200 Series line of thermal/thermal-transfer printers handle pressure-sensitive labels and tags in sizes from 3.54 to 8.8 in. wide and 20.0 to 39.0 in. long. Print speeds range from 4 to 12 in./sec, with print resolutions of 203, 300, or 600 dpi. Labels may be printed one at a time, in strips, or in large batches. Optional feature rewinds labels inside unit in preparation for automatic...

Read More »