Labthink International, Inc.

Medford, MA 02155

IT-based Control System enhances packaging safety.

Providing data management services, ULab Testing Data Integrated Platform helpsÃ- companies establish IT-based packaging safety control system. Factory testing data management focuses on testing data automatic management and intelligent analysis forÃ- facilities with self-established laboratories/quality control centers. Also included, testing center data management offers companies...

Read More »

i-Strentek Tensile Tester Supports Stretching and Compression

The newly updated i-Strentek 1100 Tensile Tester is now supports stretching as well as compression testing for materials and packages. Currently, It can be used for tensile strength, compressive strength, peeling, seal strength, tearing, puncture test of plastic films and other materials. The tensile tester can be easily operated with a mouse, a keyboard, and a monitor, without requiring a PC....

Read More »

What Is Permeation?

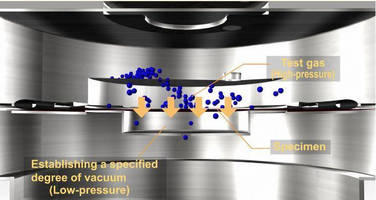

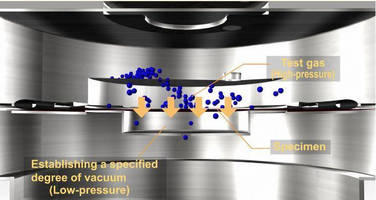

Permeation is one of the indexes indicates the barrier properties in material field. In packaging material industry, permeation is used to state and evaluate the barrier property of packaging materials against water vapor, oxygen or other gases, etc.; that is, through the evaluation of water vapor transmission rate (WVTR) testing, oxygen transmission rate (OTR) and other gas transmission rate...

Read More »

Packaging Testing Tools suit manufacturing factory applications.

Testing systems ofÃ- Ã- i-Process series systemÃ- comprise 3 major parts: testing instruments, wireless data receiving unit, and control center. Used for accelerated packaging testing and QC, products include seal tester, headspace gas analyzer, volume and weight tester, leak tester, and torque tester. Each is designed mechanically and functionally available for applications in...

Read More »Labthink Packaging Safety Testing Center was Established

Labthink Packaging Safety Testing Center was established in 2000, which can be divided into Research Laboratory and Cloud Testing Center. The total area of laboratories reaches 410 m2 and testing area is 360 m2. 120 testing instruments, which are worth a total of 30 million US dollars, are utilized to perform a variety of test items including barrier, tensile property, heat seal, hot tack, COF,...

Read More »Labthink Cloud Testing Center was Founded

Cloud Testing Center was founded in 2012 for material inspection and ULab testing service. It is equipped with Labthink's latest i-series packaging testing instruments and an intelligent laboratory management system-Cloud Testing Management System. The system is developed based on the Internet of Things and Cloud Computing technology and effectively integrates testing instruments, data, workflow,...

Read More »Labthink 2014 Spring Permeability Proficiency Service Came to a Successful Conclusion

In order to provide reliable and accurate test data verification service, Labthink organized The 2014 Spring Permeability Proficiency Service. The event, guided and supervised by authoritative experts of domestic packaging industry, was widely supported and participated by testing organizations and laboratories. By June 30th 2014, more than 120 organizations and laboratories submitted the test...

Read More »IT-based Control System enhances packaging safety.

Providing data management services, ULab Testing Data Integrated Platform helpsÃ- companies establish IT-based packaging safety control system. Factory testing data management focuses on testing data automatic management and intelligent analysis forÃ- facilities with self-established laboratories/quality control centers. Also included, testing center data management offers companies...

Read More »

i-Strentek Tensile Tester Supports Stretching and Compression

The newly updated i-Strentek 1100 Tensile Tester is now supports stretching as well as compression testing for materials and packages. Currently, It can be used for tensile strength, compressive strength, peeling, seal strength, tearing, puncture test of plastic films and other materials. The tensile tester can be easily operated with a mouse, a keyboard, and a monitor, without requiring a PC....

Read More »

What Is Permeation?

Permeation is one of the indexes indicates the barrier properties in material field. In packaging material industry, permeation is used to state and evaluate the barrier property of packaging materials against water vapor, oxygen or other gases, etc.; that is, through the evaluation of water vapor transmission rate (WVTR) testing, oxygen transmission rate (OTR) and other gas transmission rate...

Read More »

Packaging Testing Tools suit manufacturing factory applications.

Testing systems ofÃ- Ã- i-Process series systemÃ- comprise 3 major parts: testing instruments, wireless data receiving unit, and control center. Used for accelerated packaging testing and QC, products include seal tester, headspace gas analyzer, volume and weight tester, leak tester, and torque tester. Each is designed mechanically and functionally available for applications in...

Read More »Influence of Temperature Fluctuation on the Barrier Property of the Material

This article is to discuss the reasons why the temperature fluctuation could influence the barrier property of the material. KeywordF Temperature fluctuation, barrier property, permeance, high polymer As is known to all, temperature fluctuation could cause a great change in the barrier property of the polymer. There are mainly 2 factors, structure and permeation characteristics, which influence...

Read More »