Ultraflex Power Technologies

Ronkonkoma, NY 11779

Ultraflex Induction Brazing Steel Parts in Under 8 Seconds

[July 17th, 2019] UltraFlex Power Technologies - a leading manufacturer of digitally controlled induction heaters - recently shared the results from a customer-requested induction brazing scenario. The customer - a company operating in the sphere of Appliances and HVAC - was looking to replace the traditional torch heating-based brazing process for steel parts with induction brazing. The parts to...

Read More »

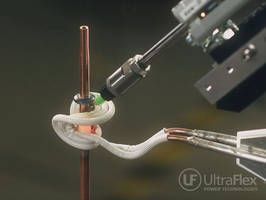

New Dragon 15 Robotic Brazing System is Capable of Brazing Multiple Joints

Features integrated induction coil mounted onto the robotic arm. Can work with 15 KW induction system and a wire feeder. Capable of programming wire feeder to start when the heating temperature had been reached.

Read More »

UltraFlex Soldering a Coaxial Cable to Connector Ring and Pin at 500-

July 5th, 2019] UltraFlex - a leading manufacturer of advanced, digitally-controlled induction heaters - has once again demonstrated the time- and cost-efficiency of induction heating for manufacturing purposes. The subject of the company’s recent demonstration had been the soldering of a coaxial cable to cable connector ring and center pin - a test scenario set up per the request of a...

Read More »UltraFlex Performing Simultaneous Induction Brazing for Copper and Brass Assemblies Within 12 Sec

The time-efficient, simultaneous induction brazing process for two copper and brass assemblies used in coolant distribution units has recently been demonstrated by UltraFlex Power Technologies. UltraFlex - a leading manufacturer of advanced, digitally controlled induction heaters - has been contacted by a HVAC equipment manufacturer to set up this induction heating demo application. The ultimate...

Read More »Ultra Flex Demonstrating a 5-Second Induction Soldering Process for An AC Wire

The extremely fast and energy-efficient induction soldering process for an AC wire has recently been demonstrated by UltraFlex Power Technologies. UltraFlex - a leading manufacturer of advanced, digitally-controlled induction heaters - is frequently setting up demos per request of potential customers looking to evaluate the parameters and results of induction-based heating. In this demo scenario,...

Read More »UltraFlex Expands Aftermarket and OEM Service Team for Induction Melting Apps

[Nov 06, 2020] UltraFlex Power Technologies recently announced that it has now considerably increased the aftermarket and OEM service team for their induction melting applications. The step has been taken following the increasing share of UltraFlex on the market for induction melting solutions and the customer demand for superior support service, minimizing costly equipment downtime. UltraFlex...

Read More »UltraFlex Induction Melting Aluminum and Iron Alloys

[Aug 25, 2020] The successful induction melting of ferromagnetic and aluminum alloys has recently been demonstrated by UltraFlex Power Technologies. The company - a leading manufacturer of induction heaters - performed the demo following a request from a customer looking to evaluate the results from the induction melting of alloys used in their manufacturing process. For this test scenario,...

Read More »Ultraflex Using Induction Heater to Preheat Steel Seat Belt Buckles

[June 1, 2020] A recent demonstration by UltraFlex Power Technologies showed the efficiency of induction preheating for steel parts used in the automotive industry. In this demonstration scenario UltraFlex - a manufacturer of advanced, digitally controlled induction heating solutions - was required to preheat to 100°C | 212°F stainless steel belt buckles in order to prepare them for plastic...

Read More »UltraFlex Demonstrates The Efficiency of Induction Hardening for Complex Shape Steel Parts

[May 25, 2020] In a recent customer-requested induction application UltraFlex Power Technologies - a leading manufacturer of induction heating solutions - proved the time- and energy-efficiency of induction hardening for steel parts used in manufacturing. In this application the customer - a manufacturing company - was looking to optimize the process of hardening for complex shape steel tools. In...

Read More »UltraFlex Offering Induction Heating Application Testing in a State-of-the-Art Applications Lab

[Apr 21, 2020] UltraFlex Power Technologies is now offering to companies the option to evaluate the benefits of induction heating for their manufacturing needs via a specially designed Applications Lab. UltraFlex is a leading provider of digitally controlled induction heating solutions and frequently shares the induction heating results achieved for a number of customer heating applications. By...

Read More »Bulgarian President Rumen Radev Visits UltraFlex Bulgaria Headquarters

On February 17th, 2020 the President of Bulgaria Rumen Radev visited UltraFlex headquarters in Sofia, Bulgaria. The visit was paid following an invitation sent by the management team of the company, which in December 2019 was recognized with the “Innovative Enterprise of Year 2019” award. The award had then been handed over to UltraFlex by the President himself. During his visit, Rumen Radev...

Read More »UltraFlex Supporting Academic Research Around the Globe

[Nov 25, 2019] UltraFlex Power Technologies - a leading manufacturer of digitally controlled induction heating solutions - has announced that it would continue supporting the academic research around the globe by enabling university students to use UltraFlex induction heating equipment in their material research and quality testing. As a manufacturer of advanced induction heating systems,...

Read More »UltraFlex Relocating its Headquarters to a Larger Facility in RONKONKOMA, NY

[Nov 12, 2019] UltraFlex Power Technologies - a leading manufacturer of advanced, digitally-controlled induction heating equipment - has announced the relocation of their Corporate Headquarters. Earlier this year, following an expansion of its activities and team, UltraFlex initiated the relocation to a newly renovated, redesigned and significantly larger facility in Ronkonkoma, NY. The new...

Read More »