Union Process, Inc.

Akron, OH 44313-4809

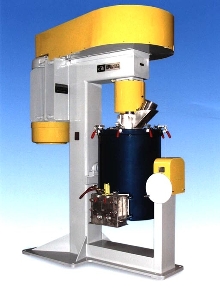

Combination Attritor is suited for grinding uranium oxide.

HSA-1/1-S combination laboratory Attritor employs single-motor system that allows user to switch back and forth between high-speed system (HSA-1), which uses 1-2 mm grinding media, and conventional system (1-S), which uses 3-10 mm sized grinding media. Each system has its own unique tank and shaft, interchangeable on frame, and MECO shaft seal for dust control. Other features include gas...

Read More »Union Process Produces Large Continuous Attritor

Akron, Ohio...Union Process, Inc., known globally as a manufacturer of size reduction and dispersing equipment as well as related services for a broad range of industrial applications, has produced a redesigned C-40 Continuous Attritor for a customer's large scale continuous production of zinc oxide and iron oxide. This C-40 Attritor features a 125 HP, T.E.F.C., inverter-duty motor with a...

Read More »

Union Process Produces Twin Q-50 Attritors for Food Industry Customer

Akron, Ohio...Union Process, a manufacturer of grinding and dispersing equipment as well as related services for a broad range of industrial applications, has designed and built two Q-50 Circulation Attritor Grinding Mills for a long-standing customer in the food service industry. Although the customer has purchased circulation Attritors from Union Process in the past, these twin Q-50 Attritors...

Read More »Union Process Produces SDL-30 Batch Attritor for Grinding Under Liquid Nitrogen

Akron, Ohio. . .Union Process, known globally as a manufacturer of size reduction and dispersing equipment for research and industrial applications, has manufactured a custom model SDL-30 dry grinding batch Attritor for a customer producing desiccants (sorbents) for the food, pharmaceutical, medical/diagnostic and electronics industries. This SDL-30 Attritor has a special cover with a Teflon...

Read More »Attritor suits cryogenic milling of aluminum powders.

Featuring cover with TeflonÃ-® shaft seal for grinding at low temperatures, Model S-50 includes vent port for liquid nitrogen as well as ports for thermocouples. Jacket around exterior of tank maintains full vacuum at temperatures as low as -320Ã-

Read More »

Grinding System processes technical ceramics.

Laboratory-sized Q-2 circulation grinding system features flame-proof electricals and is sealed for grinding under inert gas. Metal free with ceramic-lined grinding chamber, mill features zirconium oxide sleeved agitator arms and Halar coated premix/holding tank. Dual dosing/additive tanks enable adjustments to premix-holding tank, and device utilizes 2.2 gal media volume with 5-20 gal...

Read More »

Lab Mill works in continuous and circulation modes.

Model DMQ-05 small media, Ã-½-liter tank-sized mill utilizes Delta discs, eliminating shaft whip and mill vibration. Discs are indexed to provide directed and uniform media distribution throughout mill chamber. Ring screens can be adjusted to accommodate use of grinding media from 1 mm to as small as .3 mm. Large open screen area positioned at end of mill facilitates cleaning. If required,...

Read More »

Small-Media Mill requires only 0.9 qt of media volume.

Model QC-150 features QC-Mill(TM) high-circulation design. Rotor creates strong centrifugal and shearing forces inside mill, and combined with fast circulation of slurry, forces result in efficient grinding with narrow particle size distribution. Holding tank has capacity of 3-15 gal. Mill runs to max speed of 2,200 rpm with motor capacity of 7.5 hp. Simple design makes mill easy to clean and...

Read More »

Small Media Mill is available with variable frequency drive.

Model QC450 uses circulation-type process, matching flow direction to centrifugal direction. Rotor creates strong centrifugal and shearing force which, when combined with fast circulation rate of slurry, increases grinding efficiency and particle distribution. With media volume of 15 liters, mill can process batches from 50 to 400 gallons at top speed of 3,000 ft/min.

Read More »

Dry Grinders produce single micron material.

HSA Dry Grinding Attritors have side discharge screen, and media size of 1-3mm, allowing micron sized products to be generated continuously. Shaft speeds range from 400 to 1800. Devices provide dry grinding, resulting in extremely fine material. Applications include ceramic powders, glass frits, metal powders, mechanical alloying, metal oxides, fibers and celluose.

Read More »Union Process Announces Launch of New Website

Akron, Ohio, March 3, 2021 – Union Process, the world’s leading Attritor and grinding mill manufacturer, is pleased to announce the launch of its newly designed website. The new website features a modern, streamlined design, improved functionality, and more readily accessible information. This dynamic site provides easy access to information regarding UP’s wide array of solutions for...

Read More »Union Process Upgrades Pilot Plant Grinding Mills

Akron, Ohio. . .Union Process, Inc., known globally as a manufacturer of particle size reduction and dispersing equipment, as well as a supplier of grinding media and materials characterization services for a broad range of research and industrial applications, has built a new Attritor S-10/15 for its in-house pilot plant. Chuck Major, sales manager with the company, noted, This versatile design...

Read More »Union Process Updates Lab Equipment

Akron, Ohio. . .Union Process, Inc., known globally as a manufacturer of particle size reduction and dispersing equipment, as well as a supplier of grinding media and materials characterization services for a broad range of research and industrial applications, has built and installed a new laboratory-sized DMQX™ Bead Mill in its lab for the purpose of testing customers' material. Union...

Read More »Union Process Earns ISO 9001:2008 with Design Certification

Akron, OHÃ- – Union Process, Inc., known globally as a manufacturer of particle size reduction and dispersing equipment as well as related services for a broad range of research and industrial applications, has been certified to ISO 9001:2008 with Design. The quality assurance process was achieved over several months with the culmination coming in April of 2014. The quality management...

Read More »Union Process Hosts University of Akron Class to Provide Overview of Fine Grinding of Metals

Akron, OH – Union Process, Inc., known globally as a manufacturer of particle size reduction and dispersing equipment as well as related services for a broad range of research and industrial applications, recently offered a tour of its lab and production plant to a group of University of Akron graduate students studying geosciences and fine metal powder mechanical alloying (also known as...

Read More »Combination Attritor is suited for grinding uranium oxide.

HSA-1/1-S combination laboratory Attritor employs single-motor system that allows user to switch back and forth between high-speed system (HSA-1), which uses 1-2 mm grinding media, and conventional system (1-S), which uses 3-10 mm sized grinding media. Each system has its own unique tank and shaft, interchangeable on frame, and MECO shaft seal for dust control. Other features include gas...

Read More »Union Process Produces Large Continuous Attritor

Akron, Ohio...Union Process, Inc., known globally as a manufacturer of size reduction and dispersing equipment as well as related services for a broad range of industrial applications, has produced a redesigned C-40 Continuous Attritor for a customer's large scale continuous production of zinc oxide and iron oxide. This C-40 Attritor features a 125 HP, T.E.F.C., inverter-duty motor with a...

Read More »

Union Process Produces Twin Q-50 Attritors for Food Industry Customer

Akron, Ohio...Union Process, a manufacturer of grinding and dispersing equipment as well as related services for a broad range of industrial applications, has designed and built two Q-50 Circulation Attritor Grinding Mills for a long-standing customer in the food service industry. Although the customer has purchased circulation Attritors from Union Process in the past, these twin Q-50 Attritors...

Read More »Union Process Produces SDL-30 Batch Attritor for Grinding Under Liquid Nitrogen

Akron, Ohio. . .Union Process, known globally as a manufacturer of size reduction and dispersing equipment for research and industrial applications, has manufactured a custom model SDL-30 dry grinding batch Attritor for a customer producing desiccants (sorbents) for the food, pharmaceutical, medical/diagnostic and electronics industries. This SDL-30 Attritor has a special cover with a Teflon...

Read More »Union Process Produces Circulation Attritor for the Latex Industry

Akron, Ohio--Union Process, a manufacturer of grinding and dispersing equipment as well as related services for a broad range of industrial applications, has designed and built a custom QL-15 circulation grinding Attritor for a European customer producing dispersions for the latex industry. The QL-15 represents a new size for the company's circulation Attritors. Q-Series mills from Union Process...

Read More »