Mayfran International

Cleveland, OH 44143

Chip Wringing Technologies Dry Up Scrap Disposal & Waste

Cost effective chip wringers help reclaim more coolant plus dry chips more thoroughly for easier, cleaner disposal - providing lower costs in both areas At IMTS 2006, Mayfran International, a world leading producer of chip handling and coolant processing systems demonstrated their ability to increase scrap values by drying chips more thoroughly, and to reclaim more metalworking fluids to save on...

Read More »

Coolant Filtering System separates fine particulates.

Installed on floor or as pit mount and using single pump, VacuFilter(TM) coolant cleaning system works with single machine tools or multiple machines. Contaminated fluids are drawn through filter media supported by septum plate to catch solids, which are pulled away for disposal by drag conveyor. Media is selected based on fluid type, workpiece materials, and process/particulate form. Indexing of...

Read More »

Coolant System monitors volume and mix ratios.

Mounted to machine coolant tank, Coolant Control Center (CCC) provides continuous real time in-line monitoring of coolant, measuring coolant concentration, PH, conductivity, temperature, and volume. System features PLC for coolant correction and programming routines for precise maintenance of machining fluids. Measuring 16.92 x 38.89 x 11.92 in., CCC has Ã-¾ in. water inlet union and works...

Read More »

Chip Conveyor features coolant filtration and separation.

ConSep single-platform chip conveyor/coolant separator removes chips and contaminates to 50 microns in size. Separator has internal chip handling (auger) system, which also handles fines and sediment, and backwash that automatically cycles to indexing filter drum's poly fiber media, making unit maintenance free. Clear access panel enables visual inspection of cleaning process, and filtered...

Read More »Magnetic Conveyor handles ferrous and non-ferrous chips.

Magna-ToteÃ-® incorporates stationary magnetic bed plate as well as conveyor with stainless steel scraper function and standard bed-style conveyance. Unit separates ferrous chip materials from coolants and conveys both ferrous chips and small non-ferrous particles. In addition to dual recovery method for optimal coolant recovery, conveyor features roller chain configuration and...

Read More »Chain Conveyor has ergonomic design for moving small parts.

Designed to convey small parts, assembly components, and fasteners, Part-ToteÃ-® features low-profile, floor-level hopper for ergonomic loading and conveyor that elevates parts to overhead feed hoppers, vibratory bowls, or storage bins. Conveyor is also suited for inter-floor use and has modular design that can be modified to match any application. Conveyor belt consists of articulated...

Read More »

Briquetter squeezes chips into briquettes.

FastPac(TM) transforms mounds of metalworking chips, strings, and nests; fines; and sludge into dense, dry, and compact briquettes. Featuring dual-stage compacting process and dual-action compression/ejection cycle, machine handles 110-6,614 lb of metal chips and swarf per hour. Materials from single machines, cell, system, or entire facility may be processed. It provides 6-8 times reduction...

Read More »

Chip Removal System incorporates coolant filtration unit.

Taking up less than 50 ftÃ-² of floor space, ConSepÃ-® 1000 combines chip removal conveyor with coolant filtration unit. It provides 50 micron nominal coolant filtration and handles and removes fingernail size or smaller chips and fines. Machine can be modified to suit application heights and lengths for any type or configuration of machine tool. System consists of single scraper...

Read More »

Coolant Separator features over-the-belt tank.

ConSepÃ-® CrosBelt(TM) Coolant Cleaning Separator combines technologies of single-platform chip conveyor and coolant cleaning system with sloped bottom coolant tank integrated into vertical orientation. Large clean out portals at bottom facilitate sludge removal and cleaning. Since ports are located at bottom of tank, pump equipment and filter devices do not have to be removed and...

Read More »

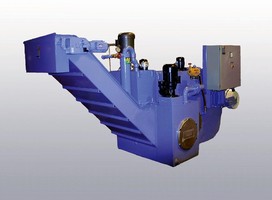

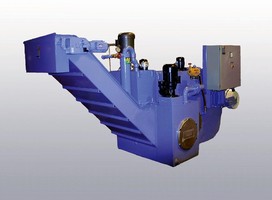

Chip Wringers facilitate coolant reclamation.

Series VBU can be used at single machine or integrated into machining cell, machining system, or factory-wide chip handling system to separate coolant, dry chips, and discharge both in unattended operation. Model VBU-300 offers steel chip handling capacity of 150 l/hr, while Model VBU-1000 handles 500 l/h, and Model VBU-200 processes up to 1,000 l/h. Larger capacity Models VBU-4000 and VBU-6000...

Read More »Reclaiming Waste and Reclaiming the Future in Hamtramck Michigan

In the heart of Hamtramck, Michigan, sits a bright, clean new building surrounded by freshly landscaped grounds. It’s home to a new business called the Hamtramck Recycling Transfer Station. Ordinarily that wouldn’t be news, except that when you compare this attractive new 33,000 sq.ft. facility with the recycling business that had previously occupied the spot, you begin to get an inkling that...

Read More »Mayfran Acquires Canadian Conveyor Firm

Mayfran International, a Cleveland, Ohio based manufacturer of engineered factory automation systems, has expanded its product capabilities with the acquisition of Press Room Techniques (PRT) of Lindsay, Ontario. PRT is the developer and manufacturer of a line of patented products that manage scrap in stamping operations. PRT's innovative shuffle conveyor systems, manufactured in Canada,...

Read More »Chip Wringing Technologies Dry Up Scrap Disposal & Waste

Cost effective chip wringers help reclaim more coolant plus dry chips more thoroughly for easier, cleaner disposal - providing lower costs in both areas At IMTS 2006, Mayfran International, a world leading producer of chip handling and coolant processing systems demonstrated their ability to increase scrap values by drying chips more thoroughly, and to reclaim more metalworking fluids to save on...

Read More »

Coolant Filtering System separates fine particulates.

Installed on floor or as pit mount and using single pump, VacuFilter(TM) coolant cleaning system works with single machine tools or multiple machines. Contaminated fluids are drawn through filter media supported by septum plate to catch solids, which are pulled away for disposal by drag conveyor. Media is selected based on fluid type, workpiece materials, and process/particulate form. Indexing of...

Read More »

Coolant System monitors volume and mix ratios.

Mounted to machine coolant tank, Coolant Control Center (CCC) provides continuous real time in-line monitoring of coolant, measuring coolant concentration, PH, conductivity, temperature, and volume. System features PLC for coolant correction and programming routines for precise maintenance of machining fluids. Measuring 16.92 x 38.89 x 11.92 in., CCC has Ã-¾ in. water inlet union and works...

Read More »

Chip Conveyor features coolant filtration and separation.

ConSep single-platform chip conveyor/coolant separator removes chips and contaminates to 50 microns in size. Separator has internal chip handling (auger) system, which also handles fines and sediment, and backwash that automatically cycles to indexing filter drum's poly fiber media, making unit maintenance free. Clear access panel enables visual inspection of cleaning process, and filtered...

Read More »Magnetic Conveyor handles ferrous and non-ferrous chips.

Magna-ToteÃ-® incorporates stationary magnetic bed plate as well as conveyor with stainless steel scraper function and standard bed-style conveyance. Unit separates ferrous chip materials from coolants and conveys both ferrous chips and small non-ferrous particles. In addition to dual recovery method for optimal coolant recovery, conveyor features roller chain configuration and...

Read More »Chain Conveyor has ergonomic design for moving small parts.

Designed to convey small parts, assembly components, and fasteners, Part-ToteÃ-® features low-profile, floor-level hopper for ergonomic loading and conveyor that elevates parts to overhead feed hoppers, vibratory bowls, or storage bins. Conveyor is also suited for inter-floor use and has modular design that can be modified to match any application. Conveyor belt consists of articulated...

Read More »

Briquetter squeezes chips into briquettes.

FastPac(TM) transforms mounds of metalworking chips, strings, and nests; fines; and sludge into dense, dry, and compact briquettes. Featuring dual-stage compacting process and dual-action compression/ejection cycle, machine handles 110-6,614 lb of metal chips and swarf per hour. Materials from single machines, cell, system, or entire facility may be processed. It provides 6-8 times reduction...

Read More »

Chip Removal System incorporates coolant filtration unit.

Taking up less than 50 ftÃ-² of floor space, ConSepÃ-® 1000 combines chip removal conveyor with coolant filtration unit. It provides 50 micron nominal coolant filtration and handles and removes fingernail size or smaller chips and fines. Machine can be modified to suit application heights and lengths for any type or configuration of machine tool. System consists of single scraper...

Read More »