Yasda Precision America Corp.

Elk Grove Village, IL 60007

Micro Machining Center processes molds for LEDs.

Featuring 40,000 rpm spindle and 450 x 350 mm table with load capacity of 100 kg, YMC430 Micro Center provides XYZ travels of 400 x 300 x 250 mm. System performs positioning accuracy by ISO230-2 0.356 Ã-µm for X-axis, 0.508 Ã-µm for Y-axis, and 0.316 Ã-µm for Z-axis. Assembled on X-axis, table is controlled by linear motors and linear guide ways. Solid H-shaped column unit firmly...

Read More »

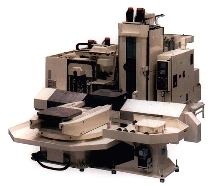

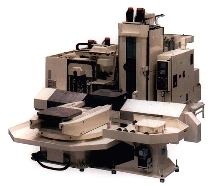

Precision Centers machine small and mid-size parts.

For stability and accuracy, Models YBM7T and YBM8T use twin ball screws and hybrid box type guide ways, positioned on either side of spindle head of Y-axis. Centers include self-adjusting system that provides large preload during low speeds for heavy cutting, and adjusts preload according to heat generated by higher speed spindle. Diaphragm coupling, co-axially connecting spindle cartridge and...

Read More »

Oil Collection Device reduces machine tool coolant waste.

Oil Pure MS-BZ features Quick Suction Pot System (Q Pot) that collects floating substances through automatic surface suction, regardless of turbulence of fluid. It requires no liquid-level adjustment after installation. Pump uses bellows-type design to separate floating substances smoothly, without further agitation. Adjustable surface levels allow users to change settings to separate fluids of...

Read More »

Machining Center handles heavy, box-shaped components.

Model YBM-10T Precision Center, capable of high-speed positioning of 45 m/min, uses twin ball screws on each of 3 axes. Ball-screw and twin servo-drive system provide vertical movement and straightness of head stock. Axial/radial combination roller bearing on B-axis allows components up to 5 tons to be rotated and positioned. Hybrid system offers load sensing and surface pressure compensation...

Read More »

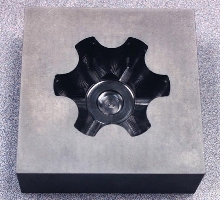

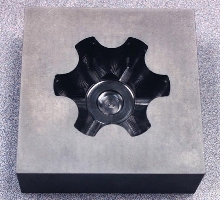

Jig Mills offer cutting capability of 90 HRC.

YBM Jig Mills feature self-adjusting preload spindle and thermal distortion stabilizing system. Combination of diamond coated cutters and Climb Cut Method results in 3D profile machining of cemented carbide 90 HRC. Applications include forming, drawing, and extrusion dies for automotive, aerospace, and consumer products industries.

Read More »

Micro Machining Center processes molds for LEDs.

Featuring 40,000 rpm spindle and 450 x 350 mm table with load capacity of 100 kg, YMC430 Micro Center provides XYZ travels of 400 x 300 x 250 mm. System performs positioning accuracy by ISO230-2 0.356 Ã-µm for X-axis, 0.508 Ã-µm for Y-axis, and 0.316 Ã-µm for Z-axis. Assembled on X-axis, table is controlled by linear motors and linear guide ways. Solid H-shaped column unit firmly...

Read More »

Precision Centers machine small and mid-size parts.

For stability and accuracy, Models YBM7T and YBM8T use twin ball screws and hybrid box type guide ways, positioned on either side of spindle head of Y-axis. Centers include self-adjusting system that provides large preload during low speeds for heavy cutting, and adjusts preload according to heat generated by higher speed spindle. Diaphragm coupling, co-axially connecting spindle cartridge and...

Read More »

Oil Collection Device reduces machine tool coolant waste.

Oil Pure MS-BZ features Quick Suction Pot System (Q Pot) that collects floating substances through automatic surface suction, regardless of turbulence of fluid. It requires no liquid-level adjustment after installation. Pump uses bellows-type design to separate floating substances smoothly, without further agitation. Adjustable surface levels allow users to change settings to separate fluids of...

Read More »

Machining Center handles heavy, box-shaped components.

Model YBM-10T Precision Center, capable of high-speed positioning of 45 m/min, uses twin ball screws on each of 3 axes. Ball-screw and twin servo-drive system provide vertical movement and straightness of head stock. Axial/radial combination roller bearing on B-axis allows components up to 5 tons to be rotated and positioned. Hybrid system offers load sensing and surface pressure compensation...

Read More »

Jig Mills offer cutting capability of 90 HRC.

YBM Jig Mills feature self-adjusting preload spindle and thermal distortion stabilizing system. Combination of diamond coated cutters and Climb Cut Method results in 3D profile machining of cemented carbide 90 HRC. Applications include forming, drawing, and extrusion dies for automotive, aerospace, and consumer products industries.

Read More »