Sugino Corp.

Itasca, IL 60143

Pressure Washing and Deburring Machines handle simple and complex parts.

Comprised of 5 modular and fully programmable machines, JET CLEAN CENTER line is designed for precision washing and deburring of simple and complex parts. Products include CLEANRISER automated Millipore patch reading system as well as JCC drying equipment that uses plant or regenerative air or vacuum technology. Depending on machine, common base, stainless steel enclosure, and internal 3-axis...

Read More »

Drilling Machine drills, counterbores, and burnishes.

Capable of precision end-milling and face-machining operations, Varimec SSV-4 quill-fed Selfeeder offers chuck capacities from 0.07-0.787 in. Mechanical-feed, 1.5 hp, electrically-driven unit, programmed through R232C port or hand-held Programming Console, comes in 2 models with no-load spindle speeds from 250-1,750 rpm and 1,000-7,000 rpm and torque from 5.24-9.07 lb-ft and 1.33-2.29 lb-ft....

Read More »

High-Pressure Washer provides controlled cavitation.

Designed to clean machined parts of cutting fluids and loose chips, U-Jet(TM) III washes up to 6 sides of complex components. Triplex pump produces water pressure to 1,015 psi and delivers it at max flow rate of 13.0 gpm and sonic velocities to 1,100 ft/sec. All washing/cleaning operations are controlled via Mitsubishi PLC controller. Unit incorporates horn nozzle design, and workspace...

Read More »

Water Deburring Center allows multi-part processing.

Jet-Clean Center 4-axis high-pressure deburring center clears chips and burrs from machined components. Large 20 x 12 x 12 in. XYZ-work area permits large part capacity and/or multi-part processing. Using 5,000 psi water and nozzle technology, unit blasts and dislodges compacted chips and debris from blind, tapped and cross holes and passages. Traveling at sonic velocities to 1,100 ft/sec, water...

Read More »

Lead-Screw Drill Units hold holemaking tolerances.

Available in 2 electrically-driven models, Varimec(TM) self-contained Selfeeder drill units are capable of end milling and face-machining operations. Quill-fed drill units include 0.5 hp SSV3 and 3.25 hp SSV5. Former has total stroke length of 7.87 in. and max cutting speed of 0.656 ips, while latter has total stroke length of 11.81 in. and max cutting speed of 0.65 ips. They incorporate internal...

Read More »

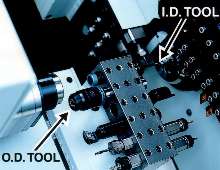

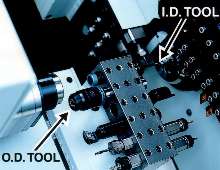

Burnishing Tools produce mirror-like finish in one pass.

Utilizing steel rollers that cold work metal surfaces, SuperollÃ-® burnishing tools offer capability to burnish IDs or ODs of any bored, reamed, or turned workpiece. This produces fine, wear-resistant finish down to 2 Ã-µin. or less in one pass. Resulting mirror-like, corrosion-resistant surface is free from irregularities. Precision adjustment feature lets operator adjust Superoll by...

Read More »

Deburring Center clears chips from critical components.

Jet-Flex 4-axis deburring machine, with 20 x 12 x 12 in. XYZ work area, permits large part capacity and/or simultaneous multi-part processing. Water pressure blasts and dislodges compacted chips and debris. Pumping station is equipped with Triplex Positive Displacement pump, capable of producing water pressure to 5,000 or 10,000 psi. All deburring operations are controlled by G-code programming...

Read More »

Parts Washer cleans complex, 6-sided components.

U-Jet III, with triplex pump, produces water pressure to 1,015 psi and delivers flow rates to 13.00 gpm. With sonic velocities to 1,100 ft/sec, washer incorporates horn nozzle-design to create controlled cavitation in washing solution. Equipment includes 200 V, 3-phase, 60 Hz electrical system; 4-axis PLC-controlled robot; automatic tank filling system; 0.15 mm wire-mesh chip filter; and oil...

Read More »Sugino, Global Leader in Precision Manufacturing Equipment, Joins OMIC R&D as 23rd Member

February 14th, 2019 - The Oregon Manufacturing Innovation Center Research and Development (OMIC R&D) welcomed Sugino Machine Limited in January 2019 as its 23rd member. With its global headquarters in Uozu, Toyama Prefecture Japan, and U.S. headquarters in Itasca, Illinois, Sugino supports a wide array of industries with precision equipment for high-pressure cleaning, machining, and many other...

Read More »Sugino Corp Expands Detroit Area Office

Sugino Corp. is pleased to announce the expansion of our Detroit Area Office to better serve the needs of our customers. Once exclusively a sales office, our facility has been expanded to include engineering, project management, and service team members. We now have nearly 13,000 sq ft of office and shop space to provide ample room for meetings with our customers and to show and demonstrate our...

Read More »Sugino Introduces Manufacturing Solutions for the Aerospace Industry

SUGINO Corp., a Japanese precision machine manufacturer with facilities worldwide, will present it’s suite of manufacturing solutions at the AeroDef Manufacturing show February 8-11, 2016 (booth 125) at the Long Beach, California Convention Center Solutions Include: The Zippel line of Aqueous Washing Systems, with washing and deburring lines tailored for high-precision aircraft engine...

Read More »Detroit Area Sales Office Now Open

We are pleased to announce the opening of a new Detroit Area Sales Office to support the needs of our customers throughout Michigan, Ohio and Ontario, Canada. SUGINO sales staff now occupies the new facility along the I-96 industrial corridor of Novi/Wixom. We are conveniently located near major automotive OEM engine and transmission manufacturing engineering centers, plants and facilities. The...

Read More »

Pressure Washing and Deburring Machines handle simple and complex parts.

Comprised of 5 modular and fully programmable machines, JET CLEAN CENTER line is designed for precision washing and deburring of simple and complex parts. Products include CLEANRISER automated Millipore patch reading system as well as JCC drying equipment that uses plant or regenerative air or vacuum technology. Depending on machine, common base, stainless steel enclosure, and internal 3-axis...

Read More »

Drilling Machine drills, counterbores, and burnishes.

Capable of precision end-milling and face-machining operations, Varimec SSV-4 quill-fed Selfeeder offers chuck capacities from 0.07-0.787 in. Mechanical-feed, 1.5 hp, electrically-driven unit, programmed through R232C port or hand-held Programming Console, comes in 2 models with no-load spindle speeds from 250-1,750 rpm and 1,000-7,000 rpm and torque from 5.24-9.07 lb-ft and 1.33-2.29 lb-ft....

Read More »

High-Pressure Washer provides controlled cavitation.

Designed to clean machined parts of cutting fluids and loose chips, U-Jet(TM) III washes up to 6 sides of complex components. Triplex pump produces water pressure to 1,015 psi and delivers it at max flow rate of 13.0 gpm and sonic velocities to 1,100 ft/sec. All washing/cleaning operations are controlled via Mitsubishi PLC controller. Unit incorporates horn nozzle design, and workspace...

Read More »

Water Deburring Center allows multi-part processing.

Jet-Clean Center 4-axis high-pressure deburring center clears chips and burrs from machined components. Large 20 x 12 x 12 in. XYZ-work area permits large part capacity and/or multi-part processing. Using 5,000 psi water and nozzle technology, unit blasts and dislodges compacted chips and debris from blind, tapped and cross holes and passages. Traveling at sonic velocities to 1,100 ft/sec, water...

Read More »

Lead-Screw Drill Units hold holemaking tolerances.

Available in 2 electrically-driven models, Varimec(TM) self-contained Selfeeder drill units are capable of end milling and face-machining operations. Quill-fed drill units include 0.5 hp SSV3 and 3.25 hp SSV5. Former has total stroke length of 7.87 in. and max cutting speed of 0.656 ips, while latter has total stroke length of 11.81 in. and max cutting speed of 0.65 ips. They incorporate internal...

Read More »

Burnishing Tools produce mirror-like finish in one pass.

Utilizing steel rollers that cold work metal surfaces, SuperollÃ-® burnishing tools offer capability to burnish IDs or ODs of any bored, reamed, or turned workpiece. This produces fine, wear-resistant finish down to 2 Ã-µin. or less in one pass. Resulting mirror-like, corrosion-resistant surface is free from irregularities. Precision adjustment feature lets operator adjust Superoll by...

Read More »