JENOPTIK Industrial Metrology

Rochester Hills, MI 48309

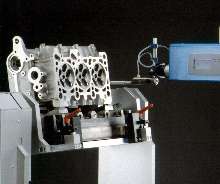

Inspection System provides 360-

Consisting of optical sensor, computer, and slide to position sensor, IPS-10 internal inspection system installs within production line to inspect bores with diameter of 14-50 mm and depths to 450 mm. Images are scanned continuously by CMOS ring sensor array and system automatically detects surface flaws such as cavities, scratches, porosity, valleys, edge flaws, and unmachined surfaces. Included...

Read More »

Roughness Measuring System operates within production line.

Featuring 10 in. touchscreen display, W55 Roughness Measurement System acquires and archives measured values of roughness, profile and waviness, and tolerances for any parameter and transfers data to statistics server via LAN interface. Up to 30 workpiece programs can be stored for different part numbers or different features. System integrates into product line and allows use of central or...

Read More »

Flexible Shaft Measuring System has -

Opticline non-contact CNC shaft gaging system measures form, dimensional, and positional tolerances of shaft-type parts in submicron detail and instantly records results. Accommodating shaft diameters from 0.2-480 mm and lengths from 1-2,500 mm, system uses calibration processes and telecentric camera measuring systems to measure complicated workpiece geometries. Optical measuring head records...

Read More »

Measuring Systems are offered in contact and noncontact types.

Opticline noncontact metrology system measures form, dimensional, and positional tolerances of symmetrical parts in submicron detail. CCM and CFM Gageline multipoint contact systems measure crankshafts and camshafts, and can measure 20 parts/hr using Windows NT measuring software. Flexible shaft gaging system accommodates shaft sizes from 0.2 to 270 mm dia, 1 to 1,500 mm long with measuring...

Read More »

Roughness Measuring System suits automotive applications.

Automotive Roughness Measuring System consists of part-specific holding fixture mounted to granite plate, and measuring head with user-selectable measuring stylus mounted to traveling vertical column. Totally automated, CNC system checks and verifies surface roughness and contours of internal engine components. It provides detailed measurement reports to document part quality and allow immediate...

Read More »Laser Processing Revolutionizes Prototype Production of Car Tires. Jenoptik and 4JET Jointly Launch New Technology.

(Jena / Alsdorf, February 22, 2021) JENOPTIK's Light & Production Division announces cooperation with the 4JET Group to jointly drive the commercialization of innovative laser prototyping technology. The technology enables rapid prototyping of vehicle tires through precise laser material processing. In this process, individual profiles and designs are laser-generated into tires with a smooth...

Read More »Jenoptik Expands Production Capacity with New Cleanrooms and Added Testing Capabilities

December 9, 2020 -- Jenoptik, an industry leader in high performance optical systems for healthcare and advanced manufacturing industries, announces the addition of a new class 5 cleanroom, expanded production area and new equipment to further enhance our manufacturing and testing capabilities for the 70,875 square foot Jupiter, Florida facility. Jenoptik continues to drive innovation with the...

Read More »Jenoptik Expands Production Capacity with New Cleanrooms and Added Testing Capabilities

December 9, 2020 -- Jenoptik, an industry leader in high performance optical systems for healthcare and advanced manufacturing industries, announces the addition of a new class 5 cleanroom, expanded production area and new equipment to further enhance our manufacturing and testing capabilities for the 70,875 square foot Jupiter, Florida facility. Jenoptik continues to drive innovation with the...

Read More »Tom Breen Joins JENOPTIK Optical Systems as Vice President of Sales and Marketing

May 27, 2020 -- Jenoptik Optical Systems, LLC, a leading optical systems solution provider, today announced Thomas Breen has joined the company's management team as Vice President of Sales and Marketing. Mr. Breen brings over 25 years of leadership experience in the optics and photonics industry. During his career, Mr. Breen has worked extensively in global sales leadership positions, developing...

Read More »Jenoptik Further Expands Automation Manufacturing Capacity

JENOPTIK Automotive North America LLC adds 40,850 square feet of manufacturing space to increase automation capabilities. October 10, 2018, Rochester Hills, MI, USA — Just last year, Jenoptik opened its new 100,000 square feet modern campus of engineering, production, sales and service for its metrology and laser processing business. With last year’s acquisition of Five Lakes Automation...

Read More »Jenoptik Announces the Appointment of Robin Swain as Sr. Director of the Silicon Valley Application Center

Industry expert Robin Swain joins the North American management team of Jenoptik. 03 October 2018, Jupiter, FL USA — Jenoptik, an industry leader in high performance optical systems and healthcare & industry solutions, announces the appointment of Robin Swain as Sr. Director of the Silicon Valley Application Center effective immediately. In Mr. Swain’s new role, he will be responsible for...

Read More »

Inspection System provides 360-

Consisting of optical sensor, computer, and slide to position sensor, IPS-10 internal inspection system installs within production line to inspect bores with diameter of 14-50 mm and depths to 450 mm. Images are scanned continuously by CMOS ring sensor array and system automatically detects surface flaws such as cavities, scratches, porosity, valleys, edge flaws, and unmachined surfaces. Included...

Read More »

Roughness Measuring System operates within production line.

Featuring 10 in. touchscreen display, W55 Roughness Measurement System acquires and archives measured values of roughness, profile and waviness, and tolerances for any parameter and transfers data to statistics server via LAN interface. Up to 30 workpiece programs can be stored for different part numbers or different features. System integrates into product line and allows use of central or...

Read More »

Flexible Shaft Measuring System has -

Opticline non-contact CNC shaft gaging system measures form, dimensional, and positional tolerances of shaft-type parts in submicron detail and instantly records results. Accommodating shaft diameters from 0.2-480 mm and lengths from 1-2,500 mm, system uses calibration processes and telecentric camera measuring systems to measure complicated workpiece geometries. Optical measuring head records...

Read More »

Measuring Systems are offered in contact and noncontact types.

Opticline noncontact metrology system measures form, dimensional, and positional tolerances of symmetrical parts in submicron detail. CCM and CFM Gageline multipoint contact systems measure crankshafts and camshafts, and can measure 20 parts/hr using Windows NT measuring software. Flexible shaft gaging system accommodates shaft sizes from 0.2 to 270 mm dia, 1 to 1,500 mm long with measuring...

Read More »