IMPCO Machine Tools

P.O. Box 10156

Lansing, MI 48917

Laser System reveals invisible surface finish.

Class II, CE-certified OPTI-Scan can be configured to check any machined part surface and render go/no-go signal. It utilizes lasers arranged around part fixture, each aimed at machined surface of workpiece. System is first shown pre-finished master part and then properly finished master part. Quality of reflected light indicates whether surface has been correctly finished, and results are...

Read More »

Microfinishing Machine is pneumatically operated.

Single-station Series 140M Centerless Microfinishing Machine features vertically mounted, pneumatically operated microfinishing unit, which includes abrasive film holder, guides, and indexer. It imparts micron-level surface finishes to cylindrical, single- and multi-diameter parts up to 7 in. in length, and between 0.16-1.0 in. diameter. Oscillating tooling applies fine abrasive film to rotating...

Read More »

Microfinishing Attachment improves surface finish on any material.

Microstar Microfinisher is independently controlled, mounts to any lathe or grinder, and is available in 115 or 250 Vac versions. It uses abrasive film, backed by oscillating platen in contact with workpiece. Abrasive film, available in range of grades and standard 2, 4, and 8 in. widths, is automatically indexed from 150 ft roll and can move in either direction without clutch, gearing, or...

Read More »

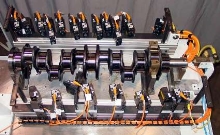

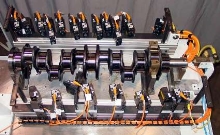

Crankshaft Finishing System changes over quickly.

Worldflex Microfinishing System achieves circular geometry and surface finish on main and pin journals. Two models handle parts from 10 to 60 in., covering 95% of world's crank sizes. Parts are loaded between headstock and tailstock mounted on slide. Tooling is mounted to end of microfinishing arms, each of which is mounted on its own independent slide. Changeover to process different parts is...

Read More »

Laser System reveals invisible surface finish.

Class II, CE-certified OPTI-Scan can be configured to check any machined part surface and render go/no-go signal. It utilizes lasers arranged around part fixture, each aimed at machined surface of workpiece. System is first shown pre-finished master part and then properly finished master part. Quality of reflected light indicates whether surface has been correctly finished, and results are...

Read More »

Microfinishing Machine is pneumatically operated.

Single-station Series 140M Centerless Microfinishing Machine features vertically mounted, pneumatically operated microfinishing unit, which includes abrasive film holder, guides, and indexer. It imparts micron-level surface finishes to cylindrical, single- and multi-diameter parts up to 7 in. in length, and between 0.16-1.0 in. diameter. Oscillating tooling applies fine abrasive film to rotating...

Read More »

Microfinishing Attachment improves surface finish on any material.

Microstar Microfinisher is independently controlled, mounts to any lathe or grinder, and is available in 115 or 250 Vac versions. It uses abrasive film, backed by oscillating platen in contact with workpiece. Abrasive film, available in range of grades and standard 2, 4, and 8 in. widths, is automatically indexed from 150 ft roll and can move in either direction without clutch, gearing, or...

Read More »

Crankshaft Finishing System changes over quickly.

Worldflex Microfinishing System achieves circular geometry and surface finish on main and pin journals. Two models handle parts from 10 to 60 in., covering 95% of world's crank sizes. Parts are loaded between headstock and tailstock mounted on slide. Tooling is mounted to end of microfinishing arms, each of which is mounted on its own independent slide. Changeover to process different parts is...

Read More »