SCHUNK

Morrisville, NC 27560

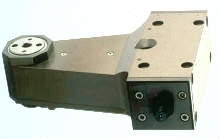

Gripper Fingers offer flexible part repositioning.

Rotary fingers for grippers allow 0 to 180 deg part repositioning while part is gripped. They are offered in 4 sizes with output torques from 0.4 to 11 Nm, and will accommodate wide range of parts. Housings are hard-coated aluminum. Double-acting, piston driven rack gear and gear train facilitate actuation while providing repeatable rotation. Thrust bearings support output shaft, and end...

Read More »