SCHUNK

Morrisville, NC 27560

Servo-Electric Grippers include position feedback.

Two-finger parallel gripper, Model EGN 100 and 3-finger centric gripper, Model EZN 64 feature integrated servomotor and encoder for position feedback and can be actuated in force or positioning mode. EGN 100 offers stroke range up to 20 mm and grip force of 600 N, while EZN 64 offers 12 mm stroke and grip force of 500 N. Supplied with 24 Vdc, external controller includes digital input and...

Read More »

Parallel Gripper is sealed to IP 67.

Pneumatic, 2-finger DPGplus is available in 7 sizes, ranging in moment capacity from 22-118 lb-ft. Each size offers option of 2 strokes and spring, for additional grip force, or safety device for OD and ID gripping. Oval piston transfers actuation to jaws through wedge-hook system. Gripper includes mounting options for magnetic switches for monitoring open, closed, or part-present position....

Read More »

Angular Gripper is designed for small parts applications.

SWG series grippers are available in 6 different sizes ranging from 8-25 mm with grip forces from 0.06-2.8 Nm. Offered with opening angle of 15Ã-

Read More »

Force/Torque Sensor widens application range for robotics.

Model FTC combines mechanical compliance and opto-electric measurement of all 6 degrees of freedom to eliminate steep rise of force at time of contact and enable fast force-regulated positioning. All electronics are incorporated within sensor and 1 kHz clock speeds allow real-time robot control. Communication is provided over protocols such as CAN bus and RS-232 or RS-485. Mechanical interface...

Read More »

Grippers offer repeatability of less than 0.0004 in.

Series MPZ 3-finger concentric grippers provide actuation speeds as fast as 20 ms. Three body sizes range from 30 to 45 mm with strokes between 6 and 10 mm, resulting in grip forces from 60 to 285 N. Spring assist models provide internal or external gripping to enhance grip force and safety in event of air loss. Gripping conditions of open, closed or part present are monitored with magnetic type...

Read More »

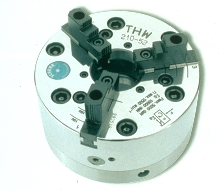

Lathe Chuck provides performance and accuracy.

THW Quick Jaw Change Series features wedge-bar serration mechanism. It provides less than one-minute jaw change, repeatability to .0006 in. TIR, and gripping forces capable of 6,000 rpm. Large Bore Power chuck line, designed to meet oil field market requirements, offers thru-hole bores to 22 in. Each Power Lathe Chuck is case hardened and ground.

Read More »

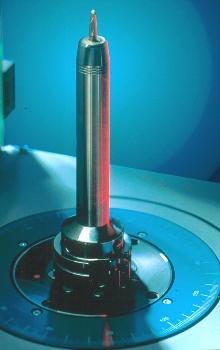

Balancing System corrects unwieldy toolholders.

ACURO PC-controlled balancing system combines balancing unit with graphical analytical software that assures that toolholders and cutting tools run true. System detects unsymmetrical toolholders or tool shapes as well as eccentric running of spindle. Precise adapter system accommodates most toolholders. Clamping is automatic via electro-pneumatic control unit that simulates operation of machine...

Read More »

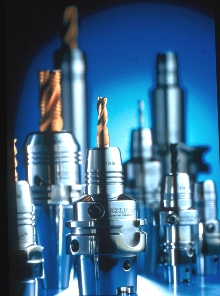

Toolholders use concentricity to hold tools.

SK, BT, and HSK toolholders are manufactured with hydraulic chucks in extended, and slim extended lengths from 63.5 to 200 mm. Guaranteed run-out of 0.0012 in. is maintained, and clamping forces are rated to 23,000 lbs. Shank-holding system with internal piston forces sleeve around cutting tool shank. Clamping area remains almost dry and high torque transmission is accomplished via metal to metal...

Read More »

Linear Slides can be air ported from multiple sides.

Nickel-phosphorus coated, high-strength aluminum-alloy Series FST and FSF enable maximizing payload and moment capacity by mounting bearing rail on moving member and integrating floating coupling with piston shafts. FST twin-piston design lifts loads to 580 N. FSF flat, single-piston design suits minimized space requirements. Bore sizes range from 6 to 25 mm with various adjustable strokes from...

Read More »

Expansion Arbors help grind gears.

FORTIS arbors clamp work pieces or tools for gear grinding and hobb sharpening. High inner pressure when actuated stretches steel concentrically, providing constant clamping and vibration dampening. Total indicator run out is less than 0.00012 in. Concentricity of arbors is maintained within 0.005 mm between OD and ID. Arbors are sealed against contamination, allowing them to be used in machining...

Read More »