SCHUNK

Morrisville, NC 27560

Clamping Vise is resistant to contamination.

KONTEC KSL stationary clamping vise allows cubic workpieces to be clamped onto universal vertical machining centers or any 4th or 5th axes table. Available in 3 sizes with base jaw widths of 100, 125, or 160 mm, mounting holes located in jaw allow mounting of workpiece stops from both sides. Actuation is done from side of the fixed jaw via allen key equipped with ratchet, and vise securely clamps...

Read More »

Clamping System integrates into optical pre-setting device.

Combination of TRIBOS clamping system and Zoller optical tool pre-setting device allows user to pre-set tooling in holder, within microns. Tooling measuring up to 15Ã-¾ in. long, with dia up to 12Ã-½ in., and weighing up to 40 lbs. can be measured on unit. Pre-setter offers accuracy within 0.001 mm on display and within 0.002 mm on concentricity, with repeatability Ã-

Read More »

Tool Holder Extension has clamping dia. of 0.012 in.

TRIBOS Micro-Mini extension allows circuit board tools with straight shanks to be held directly in holder. Clamping process requires 30 sec by means of clamping device, either manual SVP-2 or automatic clamping SVP-3, together with corresponding reduction inserts. Run-out accuracy and repeatability of extensions is less than 3 microns. Due to rotational symmetric design, basic counter balance of...

Read More »

Hydraulic Toolholders offer radial length adjustment.

TENDO clamps different types of cutting tools with cylindrical shanks directly in toolholder without using intermediate sleeves. Clamping is done by steel sleeve surrounded by hydraulic fluid, and cutting tools with different shanks are held with concentricity of less than 0.002 mm. Hydraulic, completely closed system absorbs vibrations inherent in cutting or grinding processes, resulting in...

Read More »

Toolholding System provides alternative to collet style.

With run-out accuracy of 5 microns, SINO-T provides consistent support across entire clamping zone. Actuation is performed by using C-spanner wrench. Standard unit is fine balanced to G6.3 at 15,000 rpm. Available with CAT 40 and HSK-A 63 spindle interfaces, vibration-dampening system incorporates facility for Ã-

Read More »

Heatshrink Tooling provides high production toolholding.

CELSIO Tooling guarantees true running of 0.003 mm when checked at inside end of clamping bore. Steel bodies ensure maximum toolholder life without temperature distortion. Mounting tapers are ground to grade AT3 Form A, and high-temperature as well as hardening procedures help avoid material distortion due to heating and cooling. High-frequency, 10 kW induction coil delivers fast shrinking for...

Read More »

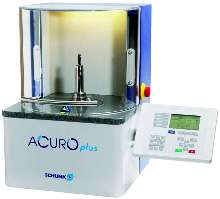

Balancing Machine is designed for toolholder systems.

Requiring 110 V power connection and 87 psi compressed air for operation, ACURO Plus can balance one complete system, consisting of toolholder and tool, within seconds in one or 2 planes. Adapter system with automatic clamping provides pulling forces equal to actual machine spindle. Balancing operations of toolholders with max weight to 33 lb and length to 13 -½ in. can be done at speeds of...

Read More »

Concentric Grippers utilize 4-finger construction.

Required when cylindrical workpieces are palletized in grid, PZV grippers incorporate serrated jaw design and wedge hook system. They can also be used as parallel grippers by mounting 2 different sets of fingers. Products also offer mounting for inductive proximity sensors with adjustable targets and integrated mounting of magnetic switches. Available in 4 sizes, units achieve grip forces from...

Read More »

Linear Axis Module handles weights up to 45 lb.

Actuated by linear motor, Series LIRAX-M-LD is constructed of drawn aluminum profile with integrated roller guides and has standard stroke length of up to 2,000 mm. Module is available in signal-drive slide version, with feed forces of 11-68 lbf, and twin-drive slide, which doubles feed force to 22 and 136 lbf, correspondingly. Module provides acceleration of 230 ft/secÃ-² and speeds up to 16...

Read More »

Gripper-Swivel Units suit automated assembly applications.

Series GSM is comprised of 3 base swivel unit sizes that can be equipped with 2-finger parallel gripper, 3-finger concentric gripper, 2-finger angular gripper, or 180Ã-

Read More »