SCHUNK

Morrisville, NC 27560

Universal Top Jaws provide form-fit clamping.

With 3 rows of clamping blades, Universal Hard Top Jaws aggressively bite into surface of work piece and can be clamped on OD or ID. Exchangeable work piece rest enables adjustment to different clamping depths with same set of jaws. Offered in 5 sizes for lathe chuck diameters 165, 210, 250, 315, and 400 mm, single set of jaws permit user to cover up to 4 clamping positions as well as bar feeding.

Read More »Workholding System utilizes electro-permanent magnets.

Available with pole sizes of 50, 75, and 100 mm, MAGNOS Magnetic workholding delivers uniform clamping force due to poles' square geometry. Additional pole extensions are available as accessories to improve workpiece location and compensate for surface irregularities. Pole extensions act as workpiece support, aiding in precise positioning of different workpieces. Use of magnets enables 5-sided...

Read More »

Lathe Chuck has design that facilitates jaw exchange.

Sealed against particle and coolant intrusion, THW-plus has jaws that can be exchanged in under 1 min and maintains gripping forces up to 6,000 rpm with wedge bar actuation system. Internal interlock prevents removal of chuck wrench when quick-change jaw is not properly installed. Center sleeve, removable from front, is available in through-hole, closed, adjustable coolant, adjustable stop, and...

Read More »

Toolholding System offers alternative to collet styles.

Available with CAT 40 or HSK-A 63 spindle interfaces, SINO-T offers vibration dampening and run-out accuracy of 5 microns. Stiff body acts as clamping medium, providing consistent support across clamping zone. Actuation is performed by C-spanner wrench. Standard version of SINO-T is fine balanced to G6.3 at 15,000 rpm, protecting machine spindle and tool's cutting edge from damage. Intermediate...

Read More »

Concentric Grippers produce 580-18,000 N grip force.

Available in 5 body sizes from 64-60 mm, 3-finger Series PZN-plus offers stroke from 12-50 mm. Gripping positions of open, closed, or part present are monitored with magnetic or inductive switches. Forces and moments of gripper are spread over several surfaces of multiple-tooth guide. Moment loading capability is maximized, allowing high external loads to be applied without damage. For part...

Read More »

Clamping Module features holding forces to 75,000 N.

Measuring 196 mm in dia, NSE 196 module is mechanically clamped and pneumatically opened, allowing clamped system to be moved in clamped state without interference from air lines. Clamping pin has a 61 mm dia through hole, which makes it possible for workpiece to protrude through clamping system. To facilitate orientation of fixture plates, module also comes with 12 mm precision bore on face.

Read More »

Concentric Clamping Vises suit space-restricted areas.

With mono-block design, PZS pneumatic clamping vise and HZS hydraulic clamping vise have no interface between cover and base body. Mechanical seal avoids chip contamination of jaw guides, and central lubrication system protects base jaws and wedge hook system against wear. Due to double air connections on bottom side, PZS can be turned 90Ã-

Read More »

Power Chuck offers clamping forces from 26-500 kN.

Providing jaw strokes from 10-18 mm per jaw, 2-Jaw Rota 2B includes integrated feed-thru and mounting features for irregular workpieces. Seals and wipers placed in crucial areas help reduce contamination of chuck body and facilitate grease retention. Chuck is suited for both turning centers and stationary applications.

Read More »

Power Lathe Chuck is sealed against chips and swarf.

Available in sizes from 165-500 mm, ROTA NCO offers clamping force from 95-330 kN with jaw strokes from 9-15 mm per jaw. Chuck is intended for vertical turning centers where contaminants are a hindrance. It offers options for automated part recognition in unmanned operations, as well as feed-through capabilities for coolant, air, or oil.

Read More »

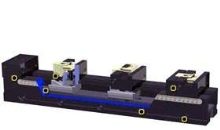

Stationary Vise offers multiple part clamping.

Available in 3 lengths, KONETEC KSM system consists of corrosion-resistant 65 or 90 mm wide clamping rail with vertical serration on inner side that allows jaws to be positioned with one hand. Based on wedge-hook principle, vise jaws are reversible and have smooth or serrated surface. Since no chips can jam rails, system is protected against damage and wear. Vise has mounting bores for assembly...

Read More »