Rubber Industries, Inc.

Shakopee, MN 55379

LIM Service produces prototype parts within 10 days.

LIMFAST(TM) Liquid Injection Molding (LIM) service offers material formulation, mold design and manufacture, silicone bonding to metal or plastic, in-house cryogenic de-flashing capabilities, component assembly, and packaging. For extended wear life, liquid silicone rubber material resists damaging effects of light, ozone, moisture, and heat. Various liquid silicone rubber grades, including UL,...

Read More »

Silicone Molded And Bonded Components Ideal For Automotive, Appliance and OEM Applications

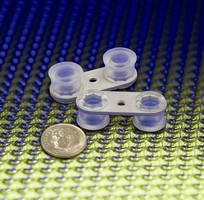

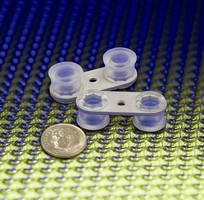

Shakopee, Minnesota: Liquid Silicone Rubber (LSR) custom injection molded parts and assemblies provide elasticity in a wide temperature range making this process a good choice for automotive, appliance, and OEM designers. Offered by Rubber Industries, Inc., both clear and custom color LSR parts and molded assemblies are available in small and large quantities. Rubber Industries LSR has a fast...

Read More »

Aging Oven tests liquid aging of elastomer compounds.

Bench Top Model 601 tests component swell and aging characteristics of molded rubber and rubber-like material formulations in fluids such as engine coolant, oil, and water at temperatures from 100-200Ã-

Read More »

Injection Molding Service utilizes liquid silicone rubber.

Liquid Injection Molding Service produces clear and colored silicon parts. Twenty-four ton Boy Presses can handle mold sizes of 10 x 12 in. and max shot size of 65 g. Molding systems utilize modular mold base, which is set up to receive cavity blocks of 4 x 4, 6 x 6, and 8 x 8 in. Liquid Silicone Rubber features temperature range of -94 to +400Ã-

Read More »

LIM Service produces prototype parts within 10 days.

LIMFAST(TM) Liquid Injection Molding (LIM) service offers material formulation, mold design and manufacture, silicone bonding to metal or plastic, in-house cryogenic de-flashing capabilities, component assembly, and packaging. For extended wear life, liquid silicone rubber material resists damaging effects of light, ozone, moisture, and heat. Various liquid silicone rubber grades, including UL,...

Read More »

Silicone Molded And Bonded Components Ideal For Automotive, Appliance and OEM Applications

Shakopee, Minnesota: Liquid Silicone Rubber (LSR) custom injection molded parts and assemblies provide elasticity in a wide temperature range making this process a good choice for automotive, appliance, and OEM designers. Offered by Rubber Industries, Inc., both clear and custom color LSR parts and molded assemblies are available in small and large quantities. Rubber Industries LSR has a fast...

Read More »

Aging Oven tests liquid aging of elastomer compounds.

Bench Top Model 601 tests component swell and aging characteristics of molded rubber and rubber-like material formulations in fluids such as engine coolant, oil, and water at temperatures from 100-200Ã-

Read More »

Injection Molding Service utilizes liquid silicone rubber.

Liquid Injection Molding Service produces clear and colored silicon parts. Twenty-four ton Boy Presses can handle mold sizes of 10 x 12 in. and max shot size of 65 g. Molding systems utilize modular mold base, which is set up to receive cavity blocks of 4 x 4, 6 x 6, and 8 x 8 in. Liquid Silicone Rubber features temperature range of -94 to +400Ã-

Read More »