Bug-O Systems

Pittsburgh, PA 15204

Share:

Welding Carriage suits semi-automatic welding.

With welding torch clamped on, 4-wheel drive, battery-operated Mini-Vert will travel and carry welding gun in flat or vertical positions, allowing production of continuous, uniform fillet welds. Quick torch mount allows welding gun to be rapidly moved from one side of machine to the other.

Read More »

Overlay System increases arc-on time and weld quality.

All Position Mechanized Overlay System consists of 2 parallel drives, tied together with cross boom for automatic indexing, and vertical drive, with torch oscillation. Weld current sensing height control is incorporated to maintain torch arc length on pitted, irregular surfaces. Suitable for rebuilding vessels and boiler tubes, portable system can be broken down for moving through small manholes...

Read More »

Welding Travel Carriage runs at speeds from 4-85 ipm.

Light'n Bug multi-purpose burning and welding travel carriage produces cuts and bevels, as well as uniform welds. Compact friction drive will ride on any standard 6 in. V-groove track, and can also be used without track for fillet welds. Circular cuts are possible with optional radius cutting attachment. Light'n Bug can be purchased as process specific kit for oxy-fuel, plasma cutting, or...

Read More »

Manipulator facilitates rapid positioning of work piece.

POKKI pipe welding manipulator secures awkward and odd shaped pipe assemblies in desired welding position, then rapidly releases and repositions as welding progresses. Work can be done with operator sitting or standing. Telescopic rotating base can be adjusted to desired height by hydro-pneumatic cylinder. Total stroke is 16 in.

Read More »

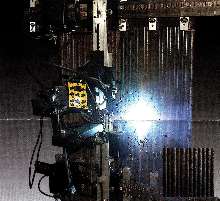

Welding Travel Carriage includes oscillation and seam tracker.

Laser-Bug sensor-controlled, 3-axis robot uses laser-camera scanner to read and automatically position MIG/MAG welding torch on butt or fillet joint. Programmable unit can perform multi-pass, multi-layer welds with automatic gap, weave, and travel speed compensation. Sensor can track one both sides of joint. Portable system measures approximately 20 x 20 x 11 in and weighs 41 lb.

Read More »

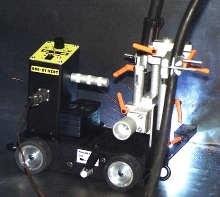

Travel Carriage holds torch in flat and vertical positions.

BUG-GY-VERT welding travel carriage uses 14.4 V rechargeable battery and magnetic base to hold torch. Guide arms track and steer into fillet joint; rail is not required to operate machine. Torch oscillator allows unit to perform weave welds. BUG-GY-VERT provides constant travel rate and precise path control.

Read More »

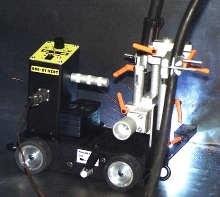

Welding Carriage suits semi-automatic welding.

With welding torch clamped on, 4-wheel drive, battery-operated Mini-Vert will travel and carry welding gun in flat or vertical positions, allowing production of continuous, uniform fillet welds. Quick torch mount allows welding gun to be rapidly moved from one side of machine to the other.

Read More »

Overlay System increases arc-on time and weld quality.

All Position Mechanized Overlay System consists of 2 parallel drives, tied together with cross boom for automatic indexing, and vertical drive, with torch oscillation. Weld current sensing height control is incorporated to maintain torch arc length on pitted, irregular surfaces. Suitable for rebuilding vessels and boiler tubes, portable system can be broken down for moving through small manholes...

Read More »

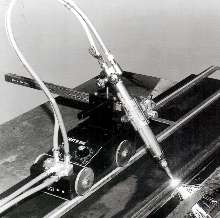

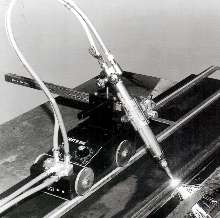

Welding Travel Carriage runs at speeds from 4-85 ipm.

Light'n Bug multi-purpose burning and welding travel carriage produces cuts and bevels, as well as uniform welds. Compact friction drive will ride on any standard 6 in. V-groove track, and can also be used without track for fillet welds. Circular cuts are possible with optional radius cutting attachment. Light'n Bug can be purchased as process specific kit for oxy-fuel, plasma cutting, or...

Read More »

Manipulator facilitates rapid positioning of work piece.

POKKI pipe welding manipulator secures awkward and odd shaped pipe assemblies in desired welding position, then rapidly releases and repositions as welding progresses. Work can be done with operator sitting or standing. Telescopic rotating base can be adjusted to desired height by hydro-pneumatic cylinder. Total stroke is 16 in.

Read More »

Welding Travel Carriage includes oscillation and seam tracker.

Laser-Bug sensor-controlled, 3-axis robot uses laser-camera scanner to read and automatically position MIG/MAG welding torch on butt or fillet joint. Programmable unit can perform multi-pass, multi-layer welds with automatic gap, weave, and travel speed compensation. Sensor can track one both sides of joint. Portable system measures approximately 20 x 20 x 11 in and weighs 41 lb.

Read More »

Travel Carriage holds torch in flat and vertical positions.

BUG-GY-VERT welding travel carriage uses 14.4 V rechargeable battery and magnetic base to hold torch. Guide arms track and steer into fillet joint; rail is not required to operate machine. Torch oscillator allows unit to perform weave welds. BUG-GY-VERT provides constant travel rate and precise path control.

Read More »