Spiroflow Systems, Inc.

Monroe, NC 28110

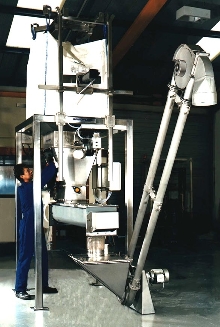

Filling System loads semi-trucks regardless of angle.

Dust-tight system includes mobile bulk bag discharger with integral aero-mechanical conveyor. Mobile unit eliminates need to build frames or gantries and can be set up by one operator. Bulk bags are lifted into place as needed by forklift. Adjustable conveying angle allows servicing of different size vehicles; throughput is unaffected by angle. Aero-mechanical conveyor is comprised of rope loop...

Read More »

Screw Conveyor handles multiple product applications.

Mobile Flexible Screw Conveyor allows use in different areas of plant facility and operation by single attendant. UHMWPE tube and steel spiral can be easily disassembled and cleaned to reduce product contamination when moving and switching products. On-board control panel can be pre-programmed. Different tube diameters and lengths are available to accommodate required rates up to 100,000 cu...

Read More »

Tensioning Device fits aero-mechanical conveyors.

Tensioning and monitoring device reduces running costs and increases wire-rope life by up to 40%. It can be fitted to most major makes of aero-mechanical conveyors.

Read More »

Bulk Bag Discharger measures loss-in-weight.

Type 3 Discharger, for single- or multiple-unit applications, places load cells between top bag holding frame and lower chute assembly, reducing load cell damage and faulty scale readings. Y-Yoke Bar Bag Spout Closures make sure bag neck is fully closed during tying and untying of bag spout. Bag stretching arms lengthen and keep bag tensioned as more powder is discharged. Pneumatic bag massagers...

Read More »

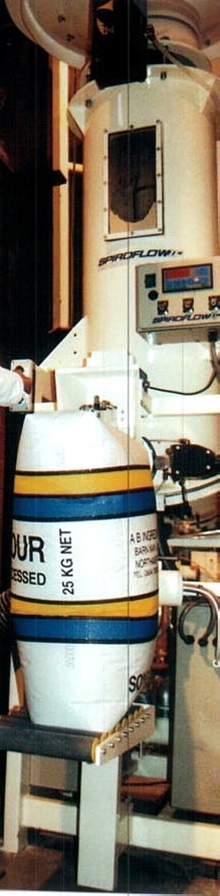

Packing System utilizes load cells and PLC controllers.

Force Flow Packer utilizes fluidization to fill bags at rates up to 5 bags per minute by supporting particles in upward airstream. During operation, powder is fluidized forcing product through filling tube. Unit is designed for 24 hour/day operation with low maintenance and minimized number of moving parts. Force Flow Packer will fill most types of paper or plastic valve bags, and 1 operator can...

Read More »

Bag Packing System can reach outputs of 12 tons/hr.

Turbo Bag Packer valve bag packing system is suited for multiple product environments where particle size and characteristics differ. Unit is designed for 24 hour/day operation. Impeller's horizontal arrangement aids in reducing turbulence during filling cycles, and results in less air in product. Inflatable valve seal and integral bag clamp provide dust control. Features include electronic...

Read More »

Bulk Bag Filler works without assistance of forklift.

Low-Loading C1-2 loads powder or granular product material into various sizes of bulk bags. Bag filling process has 6 steps. Operator places pallet on filler base and positions bulk bag on horizontal filler arms. Bag neck is placed in inflatable filler spout and tightened for dust free operation. Operator fills bag to weight or volume requirements. Low-profile filling base and detachable ramp...

Read More »