Spiroflow Systems, Inc.

Monroe, NC 28110

Flexible Screw Conveyor provides 44 tons/hr maximum output.

Available in carbon steel and stainless steel, Model 834 conveys materials at inclines up to 60Ã-

Read More »

Aero-Mechanical Conveyor handles cohesive materials.

Conveyor system, which consists of rope and disk assembly enclosed in carbon or stainless steel tubes, works with inherently sticky, cohesive materials by fluidizing them in air stream. Product can be configured in terms of distance and angles, does not require outside air supply, and can be used with other process equipment. PLC-friendly system options include bag dump stations, air purge...

Read More »

Bulk Bag Discharger handles different storage containers.

Type 7 Discharger works with bulk bags, rigid bins, or 50 lb bags. Controllable discharger and subframe with adapter allow bulk bags and bins to be fully or partially discharged. Upper frame uses sealing mechanism that eliminates product loss during discharge. To facilitate handling, bulk bag or rigid container can be placed on subframe with forklift channels. Discharger functions with flexible...

Read More »

Flexible Screw Conveyor suits food and chemical industries.

Suited for diverse applications, Flexible Screw Conveyor employs UHMWPE tube and steel spiral that can be disassembled and cleaned. It is controlled via integrated, pre-programmed PLC or by existing facility controllers. Featuring locking swivel wheels for stability, unit offers maneuverability, even in tight facility locations. Product is available in different tube diameters and lengths to...

Read More »

Bulk Bag Discharger suits single or multi-unit applications.

Type 3 Bulk Bag Discharger places sensitive loss-in-weight load cells between top bag holding frame and lower chute assembly to reduce possibility of load cell damage and faulty scale readings. Yoke bar closure ensures bag neck is fully closed during tying and untying of bag spout, while bag stretching arms lengthen and keep bag tensioned as more powder is discharged. Pneumatic bag massagers...

Read More »

Bulk Bag Dischargers offer optional closure bar system.

Bulk Bag Dischargers use yoke closure bar system for operator safety and to provide hygienic way to control powder flow. Yoke closure bars consist of series of Y-bars that cinch bulk bag spout shut, preventing powder leakage. With yoke closure bars closed, operator safety is ensured when tying and untying bulk bag. Operators can also batch and meter from bulk bags, using integral flexible screw...

Read More »

Screw Conveyor is designed for cohesive materials.

Pro ScrewÃ-® conveys difficult materials such as Titanium Dioxide, Iron Oxide, pigments, and other smearing, cohesive products. Beveled flexible screw increases product contact, thereby encouraging forward movement. Available in stainless steel, screw has throughputs of up to 15,000 lb/hr depending on bulk density and characteristics of product. Applications include processing in chemical and...

Read More »

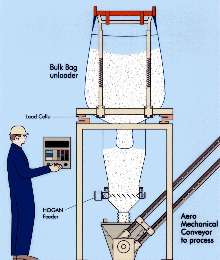

Handling System improves flow of cohesive powders.

Powder Handling System consists of Type 3 bulk bag discharger, fitted with Hogan bin discharger and aero-mechanical conveyor. By using pneumatic massage paddles and bag tensioning device, Type 3 improves material flow out of bulk bag with no dramatic degradation. Aero-mechanical conveyor creates moving current of air in which powder flows, and Hogan bin discharger acts as flow promoter by using...

Read More »

Bulk Bag Discharger fits height-restricted areas.

Measuring 10Ã-½ ft high, Type 6 bulk bag discharger incorporates low-profile hoist and unloading station. Bulk bag is untied through access door in product transfer chute directly under discharger. Independent pneumatic massage paddles aid flow of powder from bag into discharge chute and conveyor. Product is offered in carbon or stainless steel models with optional flexible screw conveyor and...

Read More »

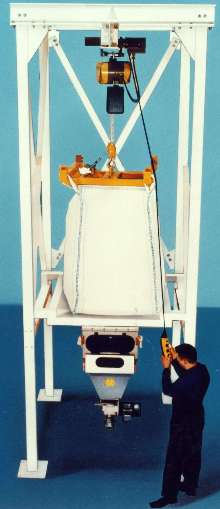

Bulk Bag Discharger incorporates hoist for bag unloading.

Type 6 Bulk Bag Discharger allows single operator to control 1 ton hoist, which positions bulk bag over discharge dish for processing, eliminating need for full time forklifts. Designed to customer specifications, unit is offered in carbon steel and 304 stainless steel designs with I-beam construction. Discharger has bag-tensioning frame, which monitors capacity/weight of bag and stretches it to...

Read More »