Almco, Inc.

Albert Lea, MN 56007

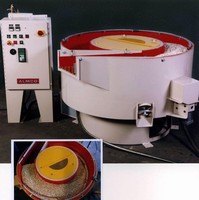

Round-Bowl Dryers use dry maize for moisture absorption.

Available with tub capacities of 3, 5, 10, and 15 ftÃ-³, OR-CD Series is suited for drying machined parts after washing and for removing surface oil and grease. Parts can be fed into machine individually or in batches, for once-around-and-out drying before next production step. Driven by 15 hp, 1,800 rpm totally enclosed motor, systems feature vertical-shaft vibrator that can be reached for...

Read More »

Tumble Blast Machine cleans castings and other metal parts.

Designed for safe operation, ATB-7 abrasive blasting machine features heavy-duty cabinet construction with structural steel members. Smartwheel(TM) blasting wheel delivers 325 lb/min of abrasive at 300 fps velocity, and double rear doors facilitate access to cabinet and screens. All motors are gear box-driven, and heavy-duty, 40 in. wide, reinforced mill belt features ribs designed to aid...

Read More »

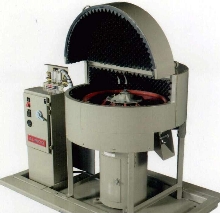

Round-Bowl Finishing Machines target non-automated shops.

Providing manual separation of metal parts and abrasive media at conclusion of deburring process, VibeMaster VM-3, VM-5, and VM-10 offer tub capacities of 3, 5.3, and 10.6 cu-ft, respectively. They are equipped with extended screen deck and thick, molded polyurethane-lined bowl for protection against part impingement. Additional features include variable adjustable amplitude, ac variable...

Read More »

Deburring/Finishing Machine features spiral design.

Model SBB-12 spiral bottom round bowl unit includes full-circle baffle that keeps parts constantly in media mass. Spiral design of up-hill tub bottom enables automatic separation of parts from abrasive media at pre-determined intervals, and allows different parts to move over separating dam to screening area without jamming or hitting. Device features 12 cu ft urethane-lined tub, 7.5 hp drive, 13...

Read More »

Rotary Parts Washer features stainless steel cabinet.

In addition to stainless steel internal components, Model RCW-36E incorporates spray system arrangement designed for maximum parts coverage. Front-loading machine occupies 4 x 4 ft footprint, and door on top permits loading of 36 in. dia turntable from overhead hoist. Work opening measures 32 in. wide x 36 in. high, and load height is 31 Ã-½ in. Along with adjustable spray pressure control...

Read More »Round-Bowl Finishing Machines offer add-on options.

Vibratory finishing equipment, available in 5 models, are offered as basic units with optional add-on features: automatic separation of parts from finishing media, automatic lubrication of vibratory bearings, and variable speed drive. Long-radius design enables once-around deburring of parts. Suited to batch and individual parts finishing, products offer tub capacities of 5, 9, 16, 25, and 40...

Read More »Repair/Upgrade Service renews vibratory finishing machines.

Available for company's vibratory finishing machines, regardless of age or type, rebuild/refurbish program is offered to extend equipment life. Engineers and technicians inspect and evaluate equipment, then report to customer with recommendations for repair or replacement of parts. After products are repaired/upgraded, they are power-washed and optionally repainted and returned to customer....

Read More »

Rotary Parts Washer is constructed of stainless steel.

Measuring 8 x 8 x 9 ft, 3-stage Model RCWR-72E accommodates up to 2,500 lb of parts and features 6 ft dia turntable. Parts, loaded from 3 x 6 ft opening at front of unit, are spray-cleaned by solution coming from adjustable nozzles at top, sides, and bottom of stainless steel cabinet. Water rinse from nozzles precedes automatic moisture blow-off prior to pail removal. Unit is suited for cleaning...

Read More »

Round-Bowl Vibrator has rotating divider and sound hood.

Model OR-3 vibratory finishing machine has rotating urethane divider that creates multiple compartments for individual part deburring, prevents damaging impingement, and eliminates fixturing of metal parts. Featuring 3 ftÃ-³ tub, unit occupies 36 x 53 in. footprint and comes with sound hood to keep noise at acceptable level. Offering constant speed of 1,750 vpm, unit enables parts to be...

Read More »

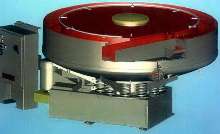

Machine facilitates finishing/deburring of metal parts.

Automated Model XLR-22 features long-radius channel that measures 22 ft x 8Ã-½ in. and provides constant media mass depth and media action. Parts are automatically separated from finishing media following once-around-and-out processing or batch cycling. Offering time cycles from 4-8 min, as well as variable amplitude and vibrations per minute, compact machine has 8Ã-¼ in. tub...

Read More »

Round-Bowl Dryers use dry maize for moisture absorption.

Available with tub capacities of 3, 5, 10, and 15 ftÃ-³, OR-CD Series is suited for drying machined parts after washing and for removing surface oil and grease. Parts can be fed into machine individually or in batches, for once-around-and-out drying before next production step. Driven by 15 hp, 1,800 rpm totally enclosed motor, systems feature vertical-shaft vibrator that can be reached for...

Read More »Almco's Custom Equipment Capabilities Emphasized in Three-Spindle Finishing Machine Literature

ALBERT LEA, Minnesota (December 13, 2010) - Four-color literature that details key features of a three-spindle finishing machine from ALMCO, Inc., and points to the company's custom design and manufacturing capabilities, is now available from the 70-year-old Minnesota firm. Developed for a long-standing customer, the Model 3SF-72RA provides fast processing of large quantities of complex metal...

Read More »Exclusive Features of Spiral-Bottom Finishing Machine Provided in New Literature from Almco

ALBERT LEA, Minnesota (November 12, 2010) - New four-color literature from ALMCO, Inc., describes a recently introduced model - the SBB-24 - in the company's line of spiral-bottom round-bowl finishing machines, offering features unmatched by other manufacturers. A unique full-circle baffle that keeps parts in the media mass constantly for faster, more precise processing is among the key features...

Read More »Almco Joins Kleentec in Combined Corporation Serving Buyers of Finishing, Cleaning Equipment

Innovance Companies Combine Sales, Administrative, Production Staffs for Efficiency, Benefit to Customers ALBERT LEA, Minnesota (October 2, 2008) - Two companies whose high-quality product lines address the metal parts deburring, finishing and cleaning equipment requirements of industrial users worldwide have been joined under the same corporate name, ALMCO KleenTec, Inc. The formerly independent...

Read More »

Tumble Blast Machine cleans castings and other metal parts.

Designed for safe operation, ATB-7 abrasive blasting machine features heavy-duty cabinet construction with structural steel members. Smartwheel(TM) blasting wheel delivers 325 lb/min of abrasive at 300 fps velocity, and double rear doors facilitate access to cabinet and screens. All motors are gear box-driven, and heavy-duty, 40 in. wide, reinforced mill belt features ribs designed to aid...

Read More »

Round-Bowl Finishing Machines target non-automated shops.

Providing manual separation of metal parts and abrasive media at conclusion of deburring process, VibeMaster VM-3, VM-5, and VM-10 offer tub capacities of 3, 5.3, and 10.6 cu-ft, respectively. They are equipped with extended screen deck and thick, molded polyurethane-lined bowl for protection against part impingement. Additional features include variable adjustable amplitude, ac variable...

Read More »

Deburring/Finishing Machine features spiral design.

Model SBB-12 spiral bottom round bowl unit includes full-circle baffle that keeps parts constantly in media mass. Spiral design of up-hill tub bottom enables automatic separation of parts from abrasive media at pre-determined intervals, and allows different parts to move over separating dam to screening area without jamming or hitting. Device features 12 cu ft urethane-lined tub, 7.5 hp drive, 13...

Read More »

Rotary Parts Washer features stainless steel cabinet.

In addition to stainless steel internal components, Model RCW-36E incorporates spray system arrangement designed for maximum parts coverage. Front-loading machine occupies 4 x 4 ft footprint, and door on top permits loading of 36 in. dia turntable from overhead hoist. Work opening measures 32 in. wide x 36 in. high, and load height is 31 Ã-½ in. Along with adjustable spray pressure control...

Read More »Round-Bowl Finishing Machines offer add-on options.

Vibratory finishing equipment, available in 5 models, are offered as basic units with optional add-on features: automatic separation of parts from finishing media, automatic lubrication of vibratory bearings, and variable speed drive. Long-radius design enables once-around deburring of parts. Suited to batch and individual parts finishing, products offer tub capacities of 5, 9, 16, 25, and 40...

Read More »Repair/Upgrade Service renews vibratory finishing machines.

Available for company's vibratory finishing machines, regardless of age or type, rebuild/refurbish program is offered to extend equipment life. Engineers and technicians inspect and evaluate equipment, then report to customer with recommendations for repair or replacement of parts. After products are repaired/upgraded, they are power-washed and optionally repainted and returned to customer....

Read More »