General Plastics Manufacturing Company

Tacoma, WA 98409

Polyurethane Insulation Blocks offer alternative to wood.

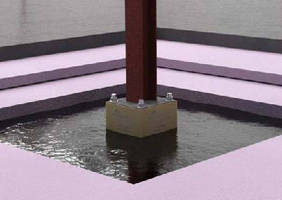

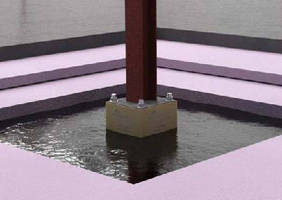

Providing thermal isolation while supporting heavy structural loads, LAST-A-FOAM-® R-9300 Continuous Insulation Blocks extend insulation from below ground to roof of industrial and cold-storage buildings. Blocks are made of high-density rigid cellular polyurethane with closed-cell structure that is inert and prevents moisture absorption. Combination of compressive strength with minimal...

Read More »General Plastics Manufacturing Company Receives Supplier of the Year Award from Boeing

Tacoma, WASH. (PRWeb) May 20, 2019 General Plastics Manufacturing Co., supplier of high-performance polyurethane foam products and built-to-print composite parts, was recognized by The Boeing Company as Supplier of the Year in the Outstanding Performance category. General Plastics was one of 13 companies honored on May 8, 2019, for its commitment to distinguished performance in working with...

Read More »General Plastics to Attend SAMPE Baltimore 2015 Conference at the Baltimore Convention Center

High-density polyurethane supplier to OEMs will exhibit products from LAST-A-FOAMÃ-® series TACOMA, Wash. – General Plastics Manufacturing Company will attend this year’s SAMPE Baltimore 2015 conference and exhibition to showcase products from the LAST-A-FOAMÃ-® rigid foam series and flexible foam parts at Booth B37. General Plastics, certified to ISO 9001:2008/AS9100C, offers foam...

Read More »General Plastics Receives 2013 Boeing Performance Excellence Award

Tacoma, Wash. – General Plastics Manufacturing Company today announced that it has received a 2013 Boeing Performance Excellence Award. The Boeing Company presents the award annually to recognize suppliers who have achieved superior performance. General Plastics maintained a Silver composite performance rating for quality and delivery each month of the 12-month performance period, from Oct. 1,...

Read More »

Polyurethane Insulation Blocks offer alternative to wood.

Providing thermal isolation while supporting heavy structural loads, LAST-A-FOAM-® R-9300 Continuous Insulation Blocks extend insulation from below ground to roof of industrial and cold-storage buildings. Blocks are made of high-density rigid cellular polyurethane with closed-cell structure that is inert and prevents moisture absorption. Combination of compressive strength with minimal...

Read More »General Plastics to Exhibit at Amerimold with Distributors

General Plastics Manufacturing Company will be participating in the Amerimold Expo 2013 in Rosemont, Illinois, and exhibiting June 12-13 at booth 313 with distribution partner Blackhawk Sales Co. The two companies will spotlight General Plastics’ LAST-A-FOAMÃ-® FR-7100 Core and Modeling Board, LAST-A-FOAMÃ-® FR-4500 Tooling Board, and LAST-A-FOAMÃ-® FR-4700 High-temperature (400...

Read More »General Plastics Signs Distributor Agreement with INDASOL

U.K. distributor to supply General Plastics' LAST-A-FOAMÃ-® sign-making and modeling blocks TACOMA, Wash., March 23, 2012 - General Plastics Manufacturing Company has named Industrial Adhesive Solutions Ltd. (INDASOL), its distributor of high-density, polyurethane foam sign-making and modeling boards in the United Kingdom. Under the agreement, INDASOL will supply customers in the U.K. with...

Read More »General Plastics Receives 2011 Boeing Performance Excellence Award

Latest award marks third consecutive silver-level honor for 50-year supplier Tacoma, WA - February 29, 2012 - General Plastics Manufacturing Company today announced that it has received a 2011 Boeing Performance Excellence Award. The Boeing Company issues the award annually to recognize suppliers who have achieved superior performance. General Plastics maintained a Silver composite performance...

Read More »General Plastics' New Boeing Contract Extends 50-Year Relationship

Three-year contract for flight deck and interior components takes effect March 1, 2012 Tacoma, WA - February 29, 2012 - General Plastics Manufacturing Company has signed a new three-year agreement with The Boeing Company. Under the contract, which includes an additional one-year option, General Plastics will supply flight deck and cabin interior components for all models of the Boeing 737, 747,...

Read More »