ATI Industrial Automation

Apex, NC 27539

Micro Robotic Tool Changer handles payloads up to 3 lb.

Weighing less than 4.3 oz, Model QC-001 enables high-speed spider or parallel-link robots to switch end-effectors automatically. Tool changer features fail-safe locking mechanism, common lock/unlock air supply and lock/unlock sensing method, four M5 pass-through air connections, and eight 3 A/50 Vac electrical connections. Positional repeatability at 1 million cycles is 0.0004 in. With QC-001,...

Read More »

Tool Changer is compatible with hollow-wrist robots.

Model QC-21HM Tool Changer allows for routing air and electrical lines directly through its center, and is compatible with all QC-21 Tool assemblies. It has Lock and Unlock sensing integrated into its design for safe Coupling and Uncoupling, and can be directly mounted to hollow-wrist robots. Unit features 8 pass-through air connections, in which 2 are Ã-¼ in. and 6 are 1/8 in. push-connect...

Read More »ATI Tool Changers Help Bring Ford's Fuel Efficiency Message to the Masses

Ford EcoBoost Display Showing at the New York Auto Show, April 2-11, 2010 Apex, NC, - When Ford Motor Company and ABB Robotics looked to create a new live robotic display to communicate the fuel efficiency message of Ford's new EcoBoost Powertrain Technology, they turned to ATI Industrial Automation for their Tool Changing needs. Debuting at the 2010 NAIAS Detroit Auto Show and on display at the...

Read More »

Tool Changer Modules communicate via Ethernet.

Featuring integrated web server, DKD Ethernet Modules control and communicate with Heavy Automation Robotic Tool Changers using Ethernet/IP(TM) while passing DeviceNet(TM) network and power to tool-side. Modules feature Arc Prevention Circuits, which protect all electrical power contacts against high inrush current during coupling/uncoupling. Provided through connector on Tool module, Tool Stand...

Read More »

Manual Tool Changers handle payloads up to 100 lb.

Designed to facilitate tool changes by hand, Models MC-16 and MC-36 feature payload limits up to 40 and 100 lb, respectively. Model MC-16 includes 4 integrated 1/8 NPT pass-through air ports, while Model MC-36 has 6. Offering multiple fail-safe features, screw-cam locking mechanism resists vibration and prevents loosening. Units also include quick-action locking for one-handed manual operation.

Read More »

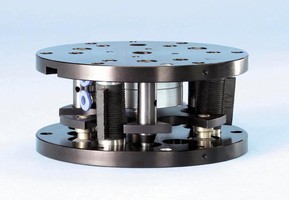

Correct Alignment Errors in Automated Assembly Applications

The Compensator, a remote center of compliance (RCC) device that is designed to correct alignment errors with peg-in-hole automated assembly applications, is available from ATI Industrial Automation, Apex, N.C. The Compensator device features shear pads that are stiff axially and compliant laterally to allow automated assembly machines to automatically correct for lateral and rotational...

Read More »

Collision Sensor suits wide variety of industrial robots.

Suited for applications using 3-5 kg capacity robots, Model SR-61 helps prevent damage to robotic end-effectors resulting from robot crashes. In operation, sensor is adjusted to support typical loads experienced by robot arm in all directions including angular, compression, and torsional. Sensor absorbs crash and resets itself within 0.001 in. of original position. Three-wire PNP proximity switch...

Read More »

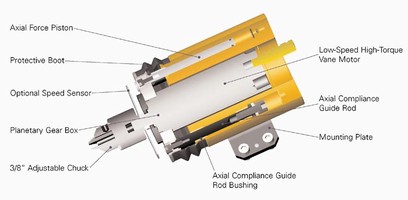

Finishing Tool compensates for irregular part patterns.

Mounted to robot or CNC machine, Flexfinish(TM) axially-compliant finishing tool features floating motor and spindle arrangement, vane-type air motor, and remotely-adjustable air pressure. Rotating spindle is equipped with 3/8 in. chuck to hold variety of finishing devices. Weighing 7.25 lb and requiring 390 W power, motor maintains working spindle speed of 2,600 rpm and compliance force is...

Read More »Finishing Tool satisfies automated finishing operations.

Suited for finishing aluminum, plastic, and steel, air-turbine-driven FlexdeburrÃ-® features floating motor and spindle arrangement that provides Ã-

Read More »

Electrical Module interfaces with robotic tool changers.

Compact, lightweight, G19-Swivel Electrical Module is used to pass electrical signals from robot side to tool side of quick-connect robotic tool changers. Cable can be positioned at any of 5 different angles through a 180Ã-

Read More »ATI Develops Space-rate Force /Torque Sensor for Mars 2020 Rover

Apex, N.C. July 23, 2020 – ATI Industrial Automation worked with NASA’s Jet Propulsion Laboratories (JPL) to develop a custom Force/Torque Sensor for Perseverance, the latest Mars 2020 Rover project. JPL is the leading US research entity for robotic exploration of our solar system and manages NASA’s Deep Space Network, the hardest-working telecommunications system on the planet. The Mars...

Read More »ATI Automation Expo Keynote Speakers and Presentation Topics Now Available

Event scheduled for May 9, 2019 at newly expanded ATI headquarters in Apex, NC Apex, N.C. April 17, 2019 – ATI Industrial Automation will host an Automation Expo May 9th, 2019 at its recently expanded and renovated headquarters in Apex, North Carolina. Customers, industry partners, and special guests will descend upon the ATI facilities for a day of inspiring discussions, new products, and...

Read More »ATI to Host an Automation Expo at its Newly Expanded Headquarters in Apex, NC

Apex, N.C. February 25, 2019 – ATI Industrial Automation will host an Automation Expo May 9th, 2019 at its recently expanded and renovated headquarters in Apex, North Carolina. For the first time ever current and prospective customers, industry partners and special guests will get a glimpse into the heart of ATI’s main operation and tour the new facility. The one-day event features...

Read More »ATI Industrial Automation's 2017 Technology Fair Set for August 10th in Orion Township, MI

APEX, N.C. May 23, 2017 – ATI Industrial Automation will hold its Annual Technology Fair on August 10, 2017 at its Orion Township, Michigan facility. The one-day educational event will focus on “Applications Advancing Automation,” providing attendees the opportunity to learn more about ATI’s products and hear from the industry-leading experts that use them every day. The event will...

Read More »ATI Industrial Automation to Break Ground on Operations Expansion, Creating 275 New Jobs

APEX, N.C. April 13, 2017 - ATI Industrial Automation will break ground on the expansion of its corporate and manufacturing headquarters in Apex, NC, on Friday, April 21, at 4:00 PM. This expansion–the largest in ATI’s 28-year history–will increase the size of its Apex facility to 185,000 square feet. “Global demand for our robotic end-effectors continues to grow,” said ATI Chairman...

Read More »ATI Industrial Automation Opens New Office in Queretaro, Mexico

Apex, North Carolina –Ã- ATI Industrial Automation, a world-leading engineering-based developer of robotic peripheral equipment, including Automatic Tool Changers, Multi-Axis Force/Torque Sensing Systems, Utility Couplers, Robotic Deburring Tools, Robotic Collision Sensors, and Compliance Devices, recently opened a new office in Queretaro, Mexico. ATI’s new office houses sales, customer...

Read More »Micro Robotic Tool Changer handles payloads up to 3 lb.

Weighing less than 4.3 oz, Model QC-001 enables high-speed spider or parallel-link robots to switch end-effectors automatically. Tool changer features fail-safe locking mechanism, common lock/unlock air supply and lock/unlock sensing method, four M5 pass-through air connections, and eight 3 A/50 Vac electrical connections. Positional repeatability at 1 million cycles is 0.0004 in. With QC-001,...

Read More »ATI Industrial Automation to Break Ground on Operations Expansion, Increasing Capacity and Creating 200 New Jobs

Apex, North Carolina: ATI Industrial Automation will break ground for an operations expansion at its corporate headquarters in Apex, North Carolina, on Friday, October 18, 2013 at 4:00pm. Driven by high demand for ATI’s end-effector products, the expansion will not only add 200 new jobs it will more than double the robotics tool manufacturing operations to 129,000 square feet. Keith Morris,...

Read More »ATI Industrial Automation's Seventh Annual Technology Training Fair Scheduled for August 22nd, 2013

Apex, North Carolina: ATI Industrial Automation will host their 7th Annual Technology Training Fair at the Michigan Sales Office located at 4577 South Lapeer Road, Suite I, Orion Township, MI 48359. On Thursday, August 22nd, discussions will detail the many new end-effector products developed by ATI over the past year along with their existing state-of-the-art products. ATI will provide...

Read More »ATI Industrial Automation Launches New Website

ATI Industrial Automation, a world-leading, engineering-based developer of robotic peripheral equipment, including Automatic Tool Changers, Multi-Axis Force/Torque Sensing Systems, Utility Couplers, Robotic Deburring Tools, Robotic Collision Sensors, and Compliance Devices, launches their new website that provides streamlined navigation and an updated look. The website is user-friendly and...

Read More »