Olympus Scientific Solutions America

Waltham, MA 02453

Olympus to Exhibit at International Conference on Metrology

Advancing optical metrology Hamburg - Olympus has today announced that it will be exhibiting at the 13th International Conference on Metrology and Properties of Engineering Surfaces. Hosted by the National Physics Laboratory (NPL), the conference will take place from 12 - 15 April 2011 at the Twickenham Stadium in London. Olympus will be promoting its expertise within the field of metrology,...

Read More »

Motorized Microscope features modular, customizable design.

Adjusting to experimental requirements, Model BX63 can be controlled via programmable touch screen, detachable remote, or cellSens software. Focusing mechanism is driven by changes in height of nosepiece, allowing stage to be fixed into position. Stage is also motorized, facilitating precise X,Y movements using ultrasonic Piezo technology. With cellSens Dimension software, users can perform...

Read More »

A Complete Concept in Personalisation

Introducing the new Olympus cellSens life science imaging software Hamburg, - Olympus has today introduced the new cellSens software for life science imaging applications. Consisting of three different packages: cellSens Entry, cellSens Standard and cellSens Dimension, all user requirements can be met with ease. Incorporating a unique user-definable interface, the imaging process can be...

Read More »

Olympus Introduces New Software for the OmniScan iX Industrial Ultrasonic Flaw Detector

The OmniScan iX Gains RPS705 Certification. Olympus is pleased to introduce the new iXU 2.1 software release for the OmniScan iX industrial ultrasonic flaw detector system that is designed for high speed nondestructive testing of industrial components. This newly revised software improves the overall ease of use of the system with a redesigned intuitive graphical that includes shortcut keys and...

Read More »

Scanner provides automated, nondestructive testing.

WeldROVER(TM) is suited for testing metal plates, pipes, vessels, and welded components from 4 in. in diameter to flat surfaces and on longseam welds 30 in. in diameter or larger. It is capable of full calibration of every focal flaw on every channel for time of flight, sensitivity, TCGDAC, and velocity. Operated via 2-button remote control and speed selection switch, 1-axis encoded, motorized...

Read More »

Olympus NDT Adds to the OmniScan MX Product Line-Two New Entry-Level, Low-Cost Modules-for Manual Phased Array Inspection

October 2006 Olympus NDT is pleased to announce the addition of the 16:16M and 16:64M manual phased array inspection modules to its OmniScan MX series. Seeing a need for a low-cost, entry-level solution for manual phased array inspection, Olympus NDT, the leader in phased array technology, has added these new entry-level flaw detectors as the newest members of the OmniScan MX product line. The...

Read More »

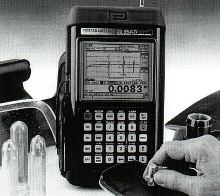

Thickness Gage ultrasonically measures multilayer materials.

Model 25MULTI PLUS ultrasonic gage can calculate and simultaneously display thickness measurements of various layers in multilayered parts. Using stored setups for each layer (such as sound velocity), gage will display up to 4 individual layers and total thickness of selected layers. Thickness range is 0.004 in. to 20 in. with resolution up to 0.0001 in. Gage works on plastic, metal, casting,...

Read More »Collaboration Helps Military Veterans Transition into NDT Careers

Olympus UT equipment supports Warrior To Inspector’s veteran training program Waltham, Mass., (November 17, 2020) — Olympus, a leading manufacturer of nondestructive testing (NDT) equipment, is supporting training school Warrior To Inspector’s mission to help transition retiring military veterans into a new NDT career by providing advanced inspection instruments for their ultrasonic...

Read More »Olympus and Hellier NDT Extend Collaboration to Train Future NDT Inspectors

Olympus’ advanced equipment supports Hellier’s UT and PAUT training Waltham, Mass., (October 14, 2020) — Furthering a partnership that began in 1986, Olympus, a leading manufacturer of innovative nondestructive testing (NDT) solutions, has supplied Hellier’s Houston, Texas location with advanced NDT inspection equipment. The industry-leading OmniScan™ X3 phased array flaw detector with...

Read More »Optimized for Offshore Corrosion Monitoring and Rope Access

Don’t forget to register for our free webinar, Advancements in Offshore Corrosion Monitoring with the EPOCH® 6LT flaw detector. Join us on February 28, 2018 to learn how the EPOCH 6LT flaw detector is advancing offshore corrosion monitoring. In this webinar, you’ll learn: How the features and specifications of the EPOCH 6LT flaw detector are designed to handle the unique challenges of...

Read More »Upcoming Webinar Series on Phased Array Inspection Using the OmniScan MX2

OLYMPUS IS HOSTING A FREE WEBINAR SERIES INTRODUCTION TO PHASED ARRAY INSPECTION USING THE OMNISCAN MX2 Olympus NDT will be hosting a free educational Webinar series titled Introduction to Phased Array Inspection Using the OmniScan MX2 that will be running throughout the first part of 2013. These webinars will take the participant through the basics of preparing a single-group phased array...

Read More »Free App for Android Phones: Industrial Tech Guide for Ultrasonic Testing and X-Ray Fluorescence

Olympus NDT is pleased to introduce the Industrial Tech Guide App for Android smart phones. Available for download on Google Play, this free Olympus mobile application contains two knowledge-based sections designed for technicians performing ultrasonic flaw detection and X-ray fluorescence (XRF) inspections. The easy-to-use Tech Guide App is a helpful tool for inspectors by providing fast and...

Read More »Olympus NDT Announces Free Webinar

Olympus NDT Announces Free Webinar Improving Small Diameter Pipe Weld Inspections with Encoded Phased Array . This free webinar scheduled for December 7 at 10.00 AM EST (15:00 GMT) and 2:00 PM (19.00 GMT) provides a brief overview of the physics of phased array ultrasound and demonstrates the benefits of this innovative technology for the inspection of small diameter piping in new construction or...

Read More »Olympus Launches Instrument Rental Program

Olympus NDT is pleased to announce the launch of its instrument rental program in the United States. Olympus NDT, a major world leader in the manufacture of nondestructive testing equipment, now has available an extensive inventory of rental equipment that includes flaw detectors, videoscopes, thickness gages, high speed video cameras, and X-ray fluorescence analyzers. Among the products...

Read More »

Olympus to Exhibit at International Conference on Metrology

Advancing optical metrology Hamburg - Olympus has today announced that it will be exhibiting at the 13th International Conference on Metrology and Properties of Engineering Surfaces. Hosted by the National Physics Laboratory (NPL), the conference will take place from 12 - 15 April 2011 at the Twickenham Stadium in London. Olympus will be promoting its expertise within the field of metrology,...

Read More »

Motorized Microscope features modular, customizable design.

Adjusting to experimental requirements, Model BX63 can be controlled via programmable touch screen, detachable remote, or cellSens software. Focusing mechanism is driven by changes in height of nosepiece, allowing stage to be fixed into position. Stage is also motorized, facilitating precise X,Y movements using ultrasonic Piezo technology. With cellSens Dimension software, users can perform...

Read More »Olympus NDT Acquires Innov-X Systems, Inc.

Olympus NDT is pleased to announce today that it has acquired Innov-X Systems Inc., a leading manufacturer of portable X-ray fluorescence (XRF) analytical instruments based in Woburn, Massachusetts, USA. Innov-X Systems instruments provide real-time, nondestructive material analysis in applications ranging from metal sorting, lead paint detection, and alloy verification to analysis of oil,...

Read More »