Northstar Polymers (Div. of Tandem Products)

Minneapolis, MN 55406

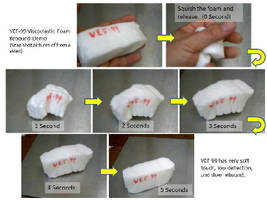

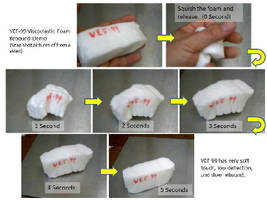

Polyurethane Foam Resin exhibits viscoelastic behavior.

Consisting of liquid polyether based polyurethane, which stays soft at very cold temperatures, VEF-99 Resin creates flexible foam for variety of custom applications. Product has very low deflection when cured and conforms to object with viscoelastic behavior. Pot life is above 30 seconds, which allows small amounts to be batched manually without dispensing machine. With mixing ratio of 1:1 by...

Read More »

Polyurethane Foam Resin exhibits viscoelastic behavior.

Consisting of liquid polyether based polyurethane, which stays soft at very cold temperatures, VEF-99 Resin creates flexible foam for variety of custom applications. Product has very low deflection when cured and conforms to object with viscoelastic behavior. Pot life is above 30 seconds, which allows small amounts to be batched manually without dispensing machine. With mixing ratio of 1:1 by...

Read More »