EFD Inc., Solder Paste Group

Lincoln, RI 02865

Processmate(TM) 3000 Linear Axis Workstation

Replacing Manual Solder Paste Operations-Tripling Your Production LINCOLN, Rhode Island - September 25, 2006 - EFD's ProcessMate(TM) 3000 is a turnkey solution that replaces inconsistent manual wire soldering processes. The workstation combines precise positioning, accurate dispensing of SolderPlusÃ-® solder paste, and a hot air reflow system. By removing guesswork from the manual soldering...

Read More »Solder Pastes are specifically formulated for SAC 305.

PrintPlusÃ-® P530 printing series and SolderPlusÃ-® D550 dispensing series consist of lead-free solder pastes with clear, colorless, no-clean flux residue that allows solder joints to be used in applications requiring shiny, cosmetic finish. Easing inspection and optimizing wetting capabilities, products are suited for SMT, mechanical, electronic, and electro-mechanical soldering...

Read More »

EFD Solder Paste Group and Leister Technologies Join in Cooperative Worldwide Marketing Effort for Advanced Tabletop Laser Soldering Reflow

Lincoln, RI (August 9, 2006) - The Solder Paste Group of EFD, Inc. and Leister Technologies LLC have agreed to a cooperative marketing effort for a unique, high-speed, high-precision, automated solder paste reflow system designed to substantially increase production yields and deliver greater throughput. Among its many advantages, the times savings alone with the EFD/Leister package could reach...

Read More »Temperature Control Unit helps optimize process control.

ProcessMate(TM) 6500 eliminates temperature fluctuations that can cause variations in shot size, viscosity, and pot life when dispensing solder pastes, adhesives, and other assembly fluids. Designed for use with air-powered benchtop dispensers and automated dispense valves, stand-alone unit maintains temperature control within Ã-

Read More »

Soldering Flux offers anti-slump characteristics.

Colorless, no-clean P520 Flux leaves clear residue for cosmetic joint finish. Printed or dispensed solder paste deposits retain shape through reflow cycle without slumping or bridging, making flux suited for fine pitch, no-clean electronic and electro-mechanical soldering applications. Flux is environmentally safe and exceeds IPC Joint Industry Standards J-STD-004A.

Read More »

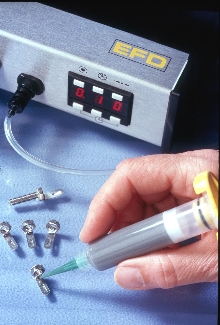

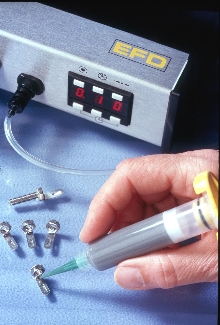

Solder Paste features colored labeling for identification.

SolderPlusÃ-® dispensable solder paste formulations are packaged in 3, 5, 10, 30, and 55 cc syringes with green end caps and green leaf label design for immediate recognition on production floor. Tin/silver, tin/silver/copper, and tin/bismuth alloys have low liquidus temperatures from 217 to 138Ã-

Read More »

Solder Paste joins hard-to-solder materials.

SolderPlus with WS421 flux offers aggressive flux chemistry that provides suitable bonding strength for mechanical assembly applications. Available in lead-free and tin/lead solder paste alloys, it is prepackaged in EFD syringes for precise application with automatic dispensing equipment. Solder paste works successfully on hard-to-solder materials such as stainless steel 304 and 316, Nichrome,...

Read More »

Solder Paste produces consistent joints without cleaning.

SolderPlus No Clean solder paste prepackaged alloy/flux blend is formulated for controlled application by automatic dispensing equipment. It provides control and speed in production soldering processes by producing consistent solder deposits without needing to remove flux residue. This tacky paste is suitable for electronic, electromechanical and telecommunications applications.

Read More »

Processmate(TM) 3000 Linear Axis Workstation

Replacing Manual Solder Paste Operations-Tripling Your Production LINCOLN, Rhode Island - September 25, 2006 - EFD's ProcessMate(TM) 3000 is a turnkey solution that replaces inconsistent manual wire soldering processes. The workstation combines precise positioning, accurate dispensing of SolderPlusÃ-® solder paste, and a hot air reflow system. By removing guesswork from the manual soldering...

Read More »Solder Pastes are specifically formulated for SAC 305.

PrintPlusÃ-® P530 printing series and SolderPlusÃ-® D550 dispensing series consist of lead-free solder pastes with clear, colorless, no-clean flux residue that allows solder joints to be used in applications requiring shiny, cosmetic finish. Easing inspection and optimizing wetting capabilities, products are suited for SMT, mechanical, electronic, and electro-mechanical soldering...

Read More »

EFD Solder Paste Group and Leister Technologies Join in Cooperative Worldwide Marketing Effort for Advanced Tabletop Laser Soldering Reflow

Lincoln, RI (August 9, 2006) - The Solder Paste Group of EFD, Inc. and Leister Technologies LLC have agreed to a cooperative marketing effort for a unique, high-speed, high-precision, automated solder paste reflow system designed to substantially increase production yields and deliver greater throughput. Among its many advantages, the times savings alone with the EFD/Leister package could reach...

Read More »Temperature Control Unit helps optimize process control.

ProcessMate(TM) 6500 eliminates temperature fluctuations that can cause variations in shot size, viscosity, and pot life when dispensing solder pastes, adhesives, and other assembly fluids. Designed for use with air-powered benchtop dispensers and automated dispense valves, stand-alone unit maintains temperature control within Ã-

Read More »

Soldering Flux offers anti-slump characteristics.

Colorless, no-clean P520 Flux leaves clear residue for cosmetic joint finish. Printed or dispensed solder paste deposits retain shape through reflow cycle without slumping or bridging, making flux suited for fine pitch, no-clean electronic and electro-mechanical soldering applications. Flux is environmentally safe and exceeds IPC Joint Industry Standards J-STD-004A.

Read More »

Solder Paste features colored labeling for identification.

SolderPlusÃ-® dispensable solder paste formulations are packaged in 3, 5, 10, 30, and 55 cc syringes with green end caps and green leaf label design for immediate recognition on production floor. Tin/silver, tin/silver/copper, and tin/bismuth alloys have low liquidus temperatures from 217 to 138Ã-

Read More »

Solder Paste joins hard-to-solder materials.

SolderPlus with WS421 flux offers aggressive flux chemistry that provides suitable bonding strength for mechanical assembly applications. Available in lead-free and tin/lead solder paste alloys, it is prepackaged in EFD syringes for precise application with automatic dispensing equipment. Solder paste works successfully on hard-to-solder materials such as stainless steel 304 and 316, Nichrome,...

Read More »

Solder Paste produces consistent joints without cleaning.

SolderPlus No Clean solder paste prepackaged alloy/flux blend is formulated for controlled application by automatic dispensing equipment. It provides control and speed in production soldering processes by producing consistent solder deposits without needing to remove flux residue. This tacky paste is suitable for electronic, electromechanical and telecommunications applications.

Read More »