REP Corporation

Kodak, TN 37764

Injection Molding Machine has 131 x 162 x 166 in. footprint.

Designed for high-production rubber molding, CMS (Compact Molding System) 4-station rotary injection press is equipped with REP injection technology and 40-ton clamping mechanism. Each station has 20.07 x 14.17 in. platens with bottom and side ejector options available on load/unload station. Featuring touchscreen controller to monitor and track all press parameters, 160-ton press is available in...

Read More »

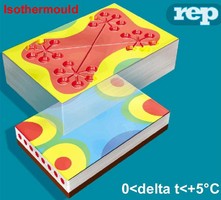

Injection Molding Presses deliver rubber part uniformity.

By utilizing Isothermould(TM) distributed power rods in press platens, G9 and G8 injection presses can consistently maintain temperature uniformity at better than Ã-

Read More »

REP Corporation NPE Booth 5139q to Display Specialized TPE Injection Press

At the upcoming NPE show, Booth 5139Q, REP Corporation, the recognized world leader in rubber injection molding machine technology, will demonstrate the V18, a recently engineered version of its popular V17, a 40-ton injection press. The V18 is specifically designed to mold demanding thermoplastic elastomer (TPE) compounds, the fastest growing need of traditional plastics and rubber molders...

Read More »Injection Presses are suited for rubber molders.

Featuring automatic speed and stroke adjustment, G9 family includes 550-ton V79 press with movable traverse located at operator level. Mold thickness adjustment is automatic, and work height is constant. With 130 x 55 in. footprint, product provides up to 31Ã-½ x 31Ã-½ in. heater platens and has L design injection head that permits floor level feeding of raw material. All presses are...

Read More »Injection Machine molds liquid silicone rubber.

For use with strip-fed rubber compounds and LSR, press offers onboard proprietary REP G8 controls and pumping/mixing station. Molds can be interchanged, and injection nozzle can be furnished with or without cold runner block valve adaptations. Press has 25 oz. shot capacity, 175-ton clamp force, and 16.93 x 20.08 in. platens. LSR shot can be delivered to mold cavity at approximately 1/3 pressure...

Read More »

Injection Press molds thermoplastic elastomers and rubbers.

Standard injection press has 4Ã-½ oz shot capacity, 30 ton clamp, and 11.81 x 11.81 in. platens. Integral input hopper loads granulated or pelletized raw materials directly to extruder screw intake. On smaller injection head unit, additional cylinder mixes materials at variable frequency to ensure complete screw chamber fill. On some models, hot oil control is replaced with electric band...

Read More »

Injection Molding Presses make dual, independent injections.

Presses make sequential or simultaneous injection of 2 materials, such as rubber, liquid silicone, or thermoplastic elastomers. Machines work 3 ways: 2 consecutive shots into adjacent cavities; simultaneous or sequential shots into single cavity; or simultaneous shots into 2 separate cavities. Onboard PC controls operation of dual injection heads, closing/clamp unit, and all other electrical,...

Read More »

Horizontal Injection Press features 340 oz shot capacity.

H48 features 200-ton capacity and 450 x 450 mm platen to accommodate larger parts. Dual brushing systems, automatic part ejectors, gripper systems, and multiple part removal conveyors can be installed under machine. On-board PC stores multiple parts programs or downloads them on LAN. Operators can see any machine parameter's set and actual values in real time. Press can be fitted with mechanical...

Read More »Jim Wirtz Named President at REP Corporation

Promises “evolution not revolution” at market leader in rubber molding presses Kodak, Tennessee - Effective immediately, James P. Wirtz II has been named President of REP Corporation, the longtime leader in rubber molding presses and related equipment for the North American market. REP Corporation is a subsidiary of REP International, based in Lyon, France. Jim Wirtz came to REP in 2014,...

Read More »REP Corporation Relocating Headquarters

Company moving HQ to Kodak, Tennessee, near Knoxville; plans to retain Chicago area facility for sales and service of its molding machinery REP Corporation (Bartlett, Illinois), the market leader in rubber molding machinery, today announces plans to relocate their corporate headquarters to Kodak, Tennessee, near Knoxville. The new facility is currently under construction and will be open in early...

Read More »LONGTIME REP CORPORATION PRESIDENT TIM GRAHAM ASSUMING NEW ROLE AT COMPANY

Graham to become Director of Special Projects, Jim Wirtz to succeed as President REP Corporation (Bartlett, Illinois), the market leader in rubber molding machinery, today announces that Tim Graham, the company’s president since 2005 and a REP employee since 1979, will assume a new role, effective January 1st 2019. Graham will become the Director of Special Projects and current After Sales...

Read More »REP Names New National Sales Director

Responding to growth in sales and expanded market opportunities, industry leader in rubber injection presses adds to staff Bartlett, IL - REP Corporation announces the appointment of Derek Williams to the new position of National Sales Director, effective immediately. This move represents a return of Mr. Williams to the REP team, where he previously served as a Regional Sales Manager. Commenting...

Read More »REP Establishes a New Production Unit in India to Serve the Indian Market

Corbas –Ã- REP International is pleased to announce the opening of its new production facility in India. REP India: REP Group’s NEW SUBSIDIARY India is having a big growth potential for rubber molders. Many international groups in the rubber industry produce locally and several others have started actions to establish there, to serve the production increase led by the automotive industry....

Read More »REP Names Jim Wirtz New Service Manager

Bartlett, IL (Chicago) – REP Corporation, longtime leader in injection and other molding presses for rubber and TPE, announces the appointment of Jim Wirtz as Service Manager for the company, effective immediately.Ã- Ã- The announcement was made at company headquarters by REP Corporation President Tim Graham.Ã- Wirtz brings nearly a lifetime of experience in the rubber molding...

Read More »Strategic Alliance for Asian Injection Molding Machine Market

Corbas/Altdorf –Ã- Two of the world’s leading manufacturers of rubber injection molding machines, German manufacturer LWB Steinl GmbH Co. KG, based in Altdorf near Munich, still run by the Steinl family, and the French company REP International based in Corbas near Lyon, have established a joint-venture to handle the exclusive sales, service and manufacturing business of rubber molding...

Read More »REP Enjoys Successful Customer Open House, Introduces New Injection Press, Celebrates 10-Year Partnership with Tung Yu

Corbas, France - On the occasion of the preview of its new V510 machine and the anniversary of its partnership with the Taiwanese company Tung Yu, Rep International hosted an Open House on June 17, 2014 at its headquarters in Corbas, near Lyon, France, resulting in a large number of customers coming together for the celebration. REP, the world leader in molding machinery for rubber and TPEs, has...

Read More »REP Names New Regional Sales Manager

Responding to growth in sales and expanded market opportunities, industry leader in rubber injection presses adds to staff Bartlett, IL – REP Corporation announces the appointment of John “JR” Mohl to the position of regional sales manager, effective immediately. JR will cover select regions of the country, representing the full line of rubber/TPE injection presses and other processing...

Read More »Devulcanization: REP Group Acquires Watson Brown HSM GmbH

Corbas - REP international, leader in the rubber injection molding machine with the head office being located in Lyon-Corbas, France, has just concluded the acquisition of the patented HSM devulcanization technology on an exclusive right basis, as well as the devulcanization center Watson-Brown HSM-Berlin. This center is equipped with an operational devulcanization line and a test laboratory...

Read More »