Engineered Pressure Systems, Inc.

Haverhill, MA 01835

Hydraulic Intensifier operates below sea level.

Hydraulically-Powered Intensifier can pump seawater 10,000 ft below sea level. It operates at discharge pressures of 30,000 psi and at environmental pressure up to 2,100 psi. Manufactured with seawater-resistant materials, unit withstands both external and internal pressure to eliminate intrusion of seawater. Intensifier is powered by hydraulic oil, uses no electrical components, and can be used...

Read More »High-Pressure Vessels provide strength and longevity.

Monobloc-Forged Vessels are forged from single ingot and can be inspected on all surfaces to establish that no cracks are developing anywhere. They can contain presence of pressure and continue operating under repeated cyclical loading conditions without failing.

Read More »

Furnace Upgrade extends life cycle of HIP systems.

Furnace Upgrade provides alternative to complete Hot Isostatic Press (HIP) replacement or rebuild. Plug-in design eliminates loading problems and reduces risk of damage to equipment. Heat shield assembly can be retrofitted into any existing HIP vessel. Furnace can be fitted for enhanced cooling to suit specific needs. Applications include castings, ceramics, plastics, automotive, and aerospace.

Read More »

Quartz Growth Systems suit high and medium pressure processes.

Hydrothermal Quartz Growth Systems constantly control temperature and pressure within forged pressure vessel. Average cycle time is 24 to 36 days, depending on size and quality of crystals required. Equipment is suitable to make quartz components used in a wide range of applications including oscillators, frequency filters, telecommunication systems, microprocessors, color televisions, and time...

Read More »

Isostatic Presses are suited for food processing industry.

Available in laboratory and production units, isostatic high-pressure presses deactivate microorganisms and enzymes and denaturate proteins and polysaccharides. They apply uniform, simultaneous, and omnidirectional pressure to food products. Non-thermal process subjects food products to isostatic pressure in 100 to 900 Mpa range at room temperature. Process also enhances retention of natural...

Read More »

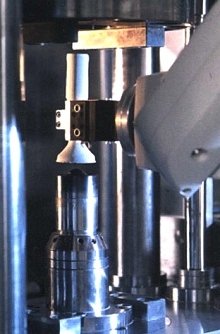

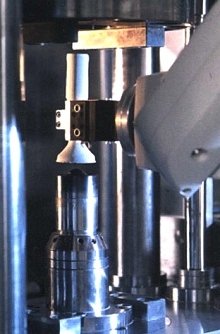

Cold Isostatic Press makes many small parts.

Dry-Bag CIP produces ceramic, carbon, plastics, and powder metal near net and net shape parts. In-line process has automatic and continuous cycling, powder filling, pressurization, decompression, and removal functions. With cycle time of 20 to 60 sec and powder fill dia of 2 to 10 in., it can be used to manufacture grinding balls, valves, tubes, rods, nozzles and implants. It can also press small...

Read More »

Press Production Unit offers interchangeable furnaces.

Hot Isostatic Press Production Unit (HIP) applies uniform pressure at elevated temperatures to all surfaces, making it suitable for castings, ceramics, plastics, automotive, and aerospace industries. Inside diameters range from 50 to 1,500 mm. Units contain pressures from vacuum to 3,000 bar and temperatures up to 4,000 deg F. They offer cascade control and fast cooling or uniform fast cooling to...

Read More »EPSI Unveils New & Innovative Website For The High-Pressure Engineering Industry

EPSI (Engineered Pressure Systems, Inc.), a world leader in custom-engineered high-pressure solutions, offers its newly updated website as a resource to the high-pressure engineering industry. Visit www.epsi-highpressure.com to obtain an in-depth view of various Hot, Cold & Warm Isostatic Press Systems, custom applications, and accessories. EPSI's updated website features English or Chinese...

Read More »Engineered Pressure Systems, Inc. Celebrates A Milestone Anniversary

Haverhill, MA - Engineered Pressure Systems, Inc. (EPSI) celebrates its 15th anniversary as a world leader in custom-engineered high-pressure solutions. Formerly a department of National Forge Company, EPSI has been a leading manufacturer of isostatic presses for over 40 years. Its Haverhill division was incorporated in 1992 and has remained a premier designer and producer of high quality Hot,...

Read More »EPSI Provides After Sales Services Worldwide

EPSI Provides After Sales Services Worldwide Engineered Pressure Systems, Inc. a world-leader in custom-engineered high pressure solutions, (no matter who supplied the equipment originally) provides after sales services for all Hot, Cold & Warm Isostatic Press Systems. With offices in Belgium and the United States, EPSI is able to provide services to any location in the world. When ever necessary...

Read More »

Hydraulic Intensifier operates below sea level.

Hydraulically-Powered Intensifier can pump seawater 10,000 ft below sea level. It operates at discharge pressures of 30,000 psi and at environmental pressure up to 2,100 psi. Manufactured with seawater-resistant materials, unit withstands both external and internal pressure to eliminate intrusion of seawater. Intensifier is powered by hydraulic oil, uses no electrical components, and can be used...

Read More »High-Pressure Vessels provide strength and longevity.

Monobloc-Forged Vessels are forged from single ingot and can be inspected on all surfaces to establish that no cracks are developing anywhere. They can contain presence of pressure and continue operating under repeated cyclical loading conditions without failing.

Read More »

Furnace Upgrade extends life cycle of HIP systems.

Furnace Upgrade provides alternative to complete Hot Isostatic Press (HIP) replacement or rebuild. Plug-in design eliminates loading problems and reduces risk of damage to equipment. Heat shield assembly can be retrofitted into any existing HIP vessel. Furnace can be fitted for enhanced cooling to suit specific needs. Applications include castings, ceramics, plastics, automotive, and aerospace.

Read More »

Quartz Growth Systems suit high and medium pressure processes.

Hydrothermal Quartz Growth Systems constantly control temperature and pressure within forged pressure vessel. Average cycle time is 24 to 36 days, depending on size and quality of crystals required. Equipment is suitable to make quartz components used in a wide range of applications including oscillators, frequency filters, telecommunication systems, microprocessors, color televisions, and time...

Read More »

Isostatic Presses are suited for food processing industry.

Available in laboratory and production units, isostatic high-pressure presses deactivate microorganisms and enzymes and denaturate proteins and polysaccharides. They apply uniform, simultaneous, and omnidirectional pressure to food products. Non-thermal process subjects food products to isostatic pressure in 100 to 900 Mpa range at room temperature. Process also enhances retention of natural...

Read More »

Cold Isostatic Press makes many small parts.

Dry-Bag CIP produces ceramic, carbon, plastics, and powder metal near net and net shape parts. In-line process has automatic and continuous cycling, powder filling, pressurization, decompression, and removal functions. With cycle time of 20 to 60 sec and powder fill dia of 2 to 10 in., it can be used to manufacture grinding balls, valves, tubes, rods, nozzles and implants. It can also press small...

Read More »

Press Production Unit offers interchangeable furnaces.

Hot Isostatic Press Production Unit (HIP) applies uniform pressure at elevated temperatures to all surfaces, making it suitable for castings, ceramics, plastics, automotive, and aerospace industries. Inside diameters range from 50 to 1,500 mm. Units contain pressures from vacuum to 3,000 bar and temperatures up to 4,000 deg F. They offer cascade control and fast cooling or uniform fast cooling to...

Read More »