Extrusion Dies Industries LLC

Chippewa Falls, WI 54729

Slot Coating Die provides streak-free application of PSAs.

Available as stand-alone system or as component of completely integrated, computer-controlled coating station, Slot Die for coating continuous-web substrates accommodates line speeds up to 2,000 fpm and achieves coat weights as low as 0.5 mil. Die includes system for adjusting cross-direction coat weight profile and device that eliminates streaking and makes clear application of pressure...

Read More »Micro-Layer Cast Film Process Yields Stretch Wrap with Enhanced Properties and Potential to Save on Wrapping Cost

CHIPPEWA FALLS, WI, February 11, 2008: Layer-multiplier technology applied by Extrusion Dies Industries, LLC (EDI) has yielded micro-layer film that stretches up to 45% more than conventional three-layer products, opening the possibility that users of stretch wrap will need fewer pounds of film to unitize a given number of pallet loads, it was announced today by EDI, which will highlight the...

Read More »

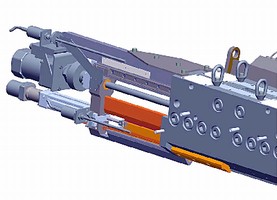

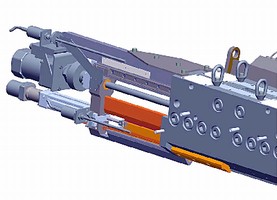

Motorized Dual Deckle automates width changes.

Featuring spring-loaded external segment, Motorized Dual Deckle minimizes or eliminates manual adjustment. It combines internal deckle, which blocks flow with blades from manifold to die lips, and external deckle, which seals off die gap from outside. AC motor drives external deckle and primary internal deckle as single unit, while smaller motor drives secondary internal deckle that fine-tunes...

Read More »Multi-Manifold Slot Dies help eliminate contamination.

Suited for proximity coating of fluids onto web substrates, dual- and triple-manifold UltracoatÃ-® dies replace multi-stage processes with single-pass coating. They enable converters to use single die to apply 2 or more coatings simultaneously, avoiding oxidation and contamination coatings can undergo between stages. Product is used in process that pre-meters coating fluid at constant rate...

Read More »Gary Edwards Becomes CEO of Extrusion Dies Industries Following Its Acquisition by Bertram Capital

Edwards Takes Charge of Bertram Capital's Program to Accelerate the Growth of EDI through Innovation, Acquisition, and International Diversification CHIPPEWA FALLS, WI, U.S.A., April 4, 2011: Gary Edwards, an experienced chief executive specializing in the strategic development of global industrial companies, has become CEO of Extrusion Dies Industries, LLC (EDI), it was announced today by...

Read More »EDI Promotes Sam G. Iuliano to Director of Technical Sales

CHIPPEWA FALLS, WI., U.S.A., January 22, 2011: Extrusion Dies Industries, LLC (EDI) has promoted Sam G. Iuliano to the position of director of technical sales, it was announced today by Dennis S. Paradise, vice president of sales and marketing. Iuliano will be responsible for providing technical support to customers, supporting EDI's field sales program, and supervising a newly created sales...

Read More »Bertram Capital to Acquire EDI, Positioning the Flat Die Manufacturer for Continued Expansion

CHIPPEWA FALLS, WI, U.S.A., December 22, 2010: Extrusion Dies Industries, LLC (EDI), a leading international supplier of flat extrusion and coating dies, announced today that it has agreed to be acquired by Bertram Capital, a private equity firm based in San Mateo, California. The parties did not disclose the terms of the transaction, which is expected to close on or around December 31, 2010....

Read More »EDI Promotes Andrei Stapinoiu to European Sales Director

SANDHURST, UK, August 25, 2010: Extrusion Dies Industries, LLC (EDI) has promoted Andrei Stapinoiu to the position of sales director for Europe, it was announced today by Dennis S. Paradise, vice president of sales and marketing. In addition to working with EDI's network of agents throughout Europe and the Middle East, Mr. Stapinoiu will now also oversee the company's agent in South Africa and...

Read More »

Slot Coating Die provides streak-free application of PSAs.

Available as stand-alone system or as component of completely integrated, computer-controlled coating station, Slot Die for coating continuous-web substrates accommodates line speeds up to 2,000 fpm and achieves coat weights as low as 0.5 mil. Die includes system for adjusting cross-direction coat weight profile and device that eliminates streaking and makes clear application of pressure...

Read More »Micro-Layer Cast Film Process Yields Stretch Wrap with Enhanced Properties and Potential to Save on Wrapping Cost

CHIPPEWA FALLS, WI, February 11, 2008: Layer-multiplier technology applied by Extrusion Dies Industries, LLC (EDI) has yielded micro-layer film that stretches up to 45% more than conventional three-layer products, opening the possibility that users of stretch wrap will need fewer pounds of film to unitize a given number of pallet loads, it was announced today by EDI, which will highlight the...

Read More »Mark D. Miller Is Appointed New Products Group Manager at EDI

CHIPPEWA FALLS, WI, U.S.A., February 14, 2008: Extrusion Dies Industries, LLC (EDI) has promoted Mark D. Miller to the new position of manager of the company's New Products Group. He will direct a team charged with developing new products and services that will provide additional value for customers and complement EDI's expertise in building feedblocks and dies for extrusion processing and web...

Read More »New EDI Technology Center to Include Trial Laboratories for Customers and R&D Labs for EDI Innovations

CHIPPEWA FALLS, WI, U.S.A., January 7, 2008: Extrusion Dies Industries, LLC (EDI) has purchased an extensive manufacturing facility very close to its headquarters site that will become the new EDI Technology Center, with laboratories for developing innovative die systems and for renting to processors and converters to use in product development and process testing. EDI expects all of the...

Read More »

Motorized Dual Deckle automates width changes.

Featuring spring-loaded external segment, Motorized Dual Deckle minimizes or eliminates manual adjustment. It combines internal deckle, which blocks flow with blades from manifold to die lips, and external deckle, which seals off die gap from outside. AC motor drives external deckle and primary internal deckle as single unit, while smaller motor drives secondary internal deckle that fine-tunes...

Read More »EDI Appoints Andrei Stapinoiu to New Position of Sales Manager for Europe and the Mideast

SANDHURST, UK, August 9, 2007: Andrei Stapinoiu has joined Extrusion Dies Industries, LLC (EDI) as European sales manager, it was announced today by Christopher W. Curtin, executive vice president of sales and marketing. Mr. Stapinoiu will be based in the United Kingdom and serve customers throughout Europe (including Russia) and the Mideast. He will work closely with EDI's long-standing agents...

Read More »