New 392x and 295x Optical Inspection Systems Achieve Unparalleled Levels of Sensitivity

Use different wavelength ranges to cover inspection applications for all layers. eDR7380 e-beam wafer defect review system provides fast defect sourcing in development, fast excursion detection and more accurate, actionable data during production. Designed to accelerate time-to-market for leading-edge 3D NAND, DRAM and logic integrated circuits (ICs) throughout their product lifecycle.

Read More »

Wire Rope Tester utilizes non-destructive testing methods.

Using non-destructive electromagnetic-inductive technology, RopeQ assesses inner and outer wires and strands of wire rope. Verifiable conditions can then be compared against discard criteria to ensure safe use. Able to detect flaws not visible on surface, tool fastens to wire rope assemblies and records series of interior images along entire length. Diagnostic survey pinpoints all areas and...

Read More »Portable GPS Current Interrupter precisely monitors corrosion.

Supplied in weatherproof case, CORI-GPS utilizes GPS technology with user-programmable, 100 ms increment interruptions for corrosion monitoring. Each portable current interrupter obtains synchronization signal via GPS satellite, and interruption can be performed with Ã-

Read More »Laser Line Sensor offers profile rate of 4,000 samples/sec.

Integrating binocular vision and laser line projection, EyeCon(TM) 2000 measures wide surface area using single Gigabit Ethernet connection, and produces high-resolution image of cross section data profiles. Direct encoder input controls global synchronization better than Ã-

Read More »

Metal Stamping for Construction Tool Applications

Metal stamping is a highly versatile manufacturing technique, capable of producing quality components at tight tolerances.

Read More »First Automotive Surface Acoustic Wave (SAW) Sensor Coupled with TI Controller Enhances Fuel Efficiency and Safety

Transense and TMS320F28x Device Brings Complete Control System Capabilities For Tire Pressure Monitoring Systems and Torque Sensing DALLAS, May 14 -- As automotive tire pressure monitoring system (TPMS) mandates come into effect and torque sensing applications like electronic power steering (EPS) become standard on even low- to mid-range cars, Texas Instruments Incorporated (TI) (NYSE:TXN) today...

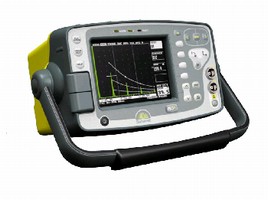

Read More »Ultrasonic Detector offers phased array flaw imaging.

When used in phased array mode, portable Phasor XS offers up to 64 channels, and operator can electronically multiplex multi-element probe to achieve control over angle of inspection, amplitude, and depth-of-focus of each ultrasonic beam. Inspection image is presented as full color, sector B-scan on TFT screen, providing comprehensive data in real-time. In conventional mode, Phasor XS uses...

Read More »

Flaw Detectors feature rugged construction.

Building on Model 123W, which is used for training organizations, Sitescan Models 150S and 250S have DAC, AVG, AWS, and API sizing techniques. Model 150S includes software features designed to optimize operator accuracy, including advanced measurement modes, full screen waveform display, and automated calibration function.

Read More »Systems detect defects and correlate them to frontside die.

Inspection tool-set, comprised of NSX(TM) and B20(TM) Systems, features backside color processing capability and auto-die classification. NSX Systems offer frontside inspection, B20 Systems offer backside inspection, and Harmony ASR(TM) (all-surface review) Software offers defect analysis and management. Combined with brightfield and darkfield capabilities, B20 Systems use color processing...

Read More »FEI Company and PDF Solutions-® Release Powerful New Semiconductor Defect Analysis Solution

Integration of FEI's Advanced DA 300HP DualBeam(TM) and PDF Solutions' CV(R) Infrastructure Helps Semiconductor Manufacturers Accelerate Yield Learning HILLSBORO, Ore., Dec. 13 / -- FEI Company (NASDAQ:FEIC), the industry leader in Tools for Nanotech(TM), and PDF Solutions, Inc., the leading provider of semiconductor process-design integration technologies and services, jointly announced the...

Read More »

Intrusion Detectors meet European security standards.

Compliant with PD6662, EN50131-1, and TS50131-2-x Grade 3, Class II standards, perimeter and indoor detectors utilize GreenLine Technology to disable MW during unset periods and Anti-Cloak(TM) Technology to detect cloaked burglars. Features include wall/back tamper, active IR for anti-mask in DT detectors, built-in EOL resistors, and 3 LEDs for walk-test. Detector types include wall- and...

Read More »

Does Your Parking Lot Make a Good First Impression?

To enhance its appearance by removing oil stains, Terminator-HSD uses micro bacteria to remove the stain without harsh chemicals, acids, or detergents. Check out the video to learn more.

Read More »