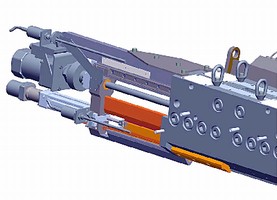

Motorized Dual Deckle automates width changes.

Featuring spring-loaded external segment, Motorized Dual Deckle minimizes or eliminates manual adjustment. It combines internal deckle, which blocks flow with blades from manifold to die lips, and external deckle, which seals off die gap from outside. AC motor drives external deckle and primary internal deckle as single unit, while smaller motor drives secondary internal deckle that fine-tunes...

Read More »

Vertical Integration vs. Outsourcing

This white paper gives an overview into key industry trends and insights regarding vertical integration vs. outsourcing and understanding how they differ.

Read More »

Custom Fabrication & Machining Services with Over 30 Years of Experience

As a trusted manufacturer to customers across a broad range of industries, Key Gas Components is a premier provider of CNC machining and tube fabrication. Our entire organization is quality driven and customer-centric, with broad-based manufacturing capabilities that can accommodate the most challenging requirements. See our video to learn more.

Read More »