Mazak to Spotlight Accurate, Affordable Milling and Turning Solutions at TECMA

FLORENCE, Ky. –Ã- At TECMA 2015, taking place March 3Ã- - 6 in Mexico City, Mazak will spotlight accurate, affordable machine tools in Stand 430 that will forever change how machine shops process small and medium-sized workpieces for a variety of industries. During the show, Mazak will run part cutting demonstrations on the VERTICAL CENTER UNIVERSAL 400A 5X, VERTICAL CENTER NEXUS 510 5X...

Read More »

GMTA News of Note

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Wera Profilator, K + G, Pittler, Praewema and WMZ, as well as Arnold lasers and Rosink parts washers.Ã- These machines are sold to the North American market exclusively by GMTA, primarily for gear and spline production, as well as other power...

Read More »

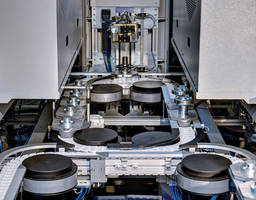

Vertical Turning DUO Cell

The machining concept of vertical pick-up machines as a modular system meets manufacturing companies' requirements for more quality, while simultaneously maintaining high flexibility and reducing cost. The right-hand and left-hand versions of the EMCO Maier VT 160 and VT 250, when linked with one of three basic conveyor options -- oval, meander, and crossover-meander designs -- provide a complete...

Read More »

Nanotech Demonstrates Most Flexible Diamond Turning System

During SPIE Photonics West 2014 in San Francisco, Nanotech will demonstrate what has become their true flagship machining system. The Nanotech 350FG is the most diverse ultra-precision machine available. Starting with a minimum of three ultra- precision axes, it is easily expandable to five axes via optional B & C rotary axes. Typical applications for this machine include axisymmetric machining...

Read More »

Must-Ask Questions When Choosing a Foam Control Agent

This eBook discusses foam controlling agents and how to find the right one for your needs.

Read More »

Mazak Midwest Event to Showcase Total Manufacturing Solutions

Attendees to discover new tools and techniques for staying ahead of the manufacturing curveÃ- FLORENCE, Ky. – Mazak invites manufacturers to its DISCOVER MORE WITH MAZAK Midwest event, taking place March 25 – 27 from 9 a.m. to 6 p.m. at the company's Technology Center in Schaumburg, Ill. The event will focus on ways to boost production efficiency through total manufacturing solutions,...

Read More »

Quicktech TTS-42/ TTS-60 9-Axis Twin Spindle Multi-Tasking Center with B Axis at PMTS in Booth #655

[LORAIN, OHÃ- - FEBRUARY 2013]Ã- Absolute Machine Tools will exhibit the Quicktech TTS-42/TTS-60 9-axis twin spindle multi-tasking turning center at PMTS in booth #655. The high precision, high production CNC bar processing center enables complete part machining including milling of complex features. Available in both 42mm and 60mm (1.65 or 2.36 ) bar capacities as the TTS-42 or TTS-60,...

Read More »

Medical Manufacturing Turns to Hardinge SUPER-PRECISION-® Gang-Tool Turning Center

Medical part manufacturing continues to be a rapidly growing market due to the large population of aging baby boomers who are looking for improved quality of life . Demand is high for high-precision components for neurological, orthopeadic, spinal/bone fixation, dental implants, drug infusion, catheter connectors, optical, maxillofacial, micro/minimally invasive, surgical instruments and other...

Read More »Swiss Screw Machining Solutions for Plastic & Metal Components

Precision Swiss screw machined components have had a major impact on the medical, aerospace and defense industry. In these industries, having the most precise components available is not an option - it's mandatory. Any product manufactured for these industries must be created using the latest in accurate manufacturing technology in order to perform exceptionally. Common Uses for Precision Swiss...

Read More »

Five New Mill-Turn Centres from Star

Of the nine CNC lathes on the Star GB stand this year, four sliding-headstock mill-turn centres and a fixed-head lathe are being shown for the first time ever at a MACH exhibition. All of the multi-axis machines are designed for long periods of unmanned production and high levels of consistent accuracy. A large range of tooling options and additional equipment allow the provision of complete...

Read More »Manufacturing System supports small batches, mass production.

Intended for turned parts manufacturers, VL 5i integrates recirculating conveyor chain with carrier prisms; fluid cooling system for spindle motor and turret; and chip conveyor. Automation equipment helps create fixed production cycle, and pick-up station behind machining area lets operator remove finished components and insert new raw-parts at front of machine. With indexing times of 2.2 sec,...

Read More »

Micro Air's Dust, Fume, Mist Collection Equipment Facilitate a Safe Work Environment

Dust, fume, and mist collectors from Micro Air promote a safer, more productive work environment. Our wide array of products are available to the industrial manufacturing sector for processes such as welding, cutting, grinding, blasting, and more. Check out our video to learn more.

Read More »