New PipeLiner Grinding and Mech Notching Wheels Developed for Pipeline Applications

Tiger Pipeliner Grinding Wheels design with a mix of top-quality abrasive grains, delivers fast cut rate and removes wagon tracks from the weld bead. Feature angle-of-use markings to ensure safe and proper use. Tiger Mech Notching Wheels are capable of grinding the starts and stops of the weld bead without widening or scarring the narrow channel.

Read More »

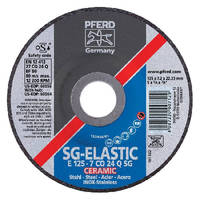

Grinding Wheels feature pure ceramic oxide grain.

Featuring hardness grade Q, Series CO 24 Q SG is suited for weld grinding, chamfering, deburring, and surface grinding. Depressed center grinding wheels employ contamination-free abrasives without fillers or blends and are rated for stainless steel (INOX). Offering optimal results on high-powered angle grinders, wheels are available in sizes from 4.5 in. diameter x Ã-¼ in. thick with max...

Read More »

BorgWarner Supplies Oil Pump Chain for JATCO CVT7 Transmission

BorgWarner's Silent Chain Provides Low-Noise, Low-Weight, Compact Solution for Minicars and Small Vehicles AUBURN HILLS, Mich. –Ã- BorgWarner supplies its 6.35 mm inverted tooth silent chain for JATCO's CVT7 continuously variable transmission. Designed for 0.66- to 1.8-liter minicars and small front-wheel drive vehicles, the CVT7 transmission propels a wide variety of automobiles, including...

Read More »

Hamilton Caster Designs New Inline Caster for Aerospace Supplier

What began as a simple inquiry for a wheel spawned into a new Hamilton innovation.Ã- The end result was a custom engineered all stainless inline caster for a major aerospace part supplier. The aerospace company ordered two of these special casters designed for a clean room environment and each with an impressive carrying capacity of 15,500 lbs.Ã- The caster stands 10 1/8” tall and...

Read More »

Top Design Engineering Considerations For Optical Assemblies

In this eBook, we provide an overview of the design engineering considerations to keep in mind when planning the manufacture of an optical assembly.

Read More »

Surface Finishing Discs work with range of materials, equipment.

Made of non-woven nylon impregnated with abrasive grain and smear-free resin, Norton Rapid Prep surface conditioning discs is suitable for surface finishing applications such as removing surface defects, oxides and corrosion, deburring, mold cleaning, and blending uneven edges and marks. Products work with right-angle grinders, in-line grinders, and die grinders and have open structure that...

Read More »Goodrich C-130 Carbon Brakes Significantly Reduce Brake Cooling Time, Enable Quicker Aircraft Turnaround

SINGAPORE, Feb. 13, 2012 - SINGAPORE AIRSHOW - Goodrich Corporation (NYSE: GR) recently completed flight testing of its new carbon brake for the U.S. Air Force's fleet of C-130 transport aircraft, demonstrating a significant reduction in brake cooling time and enabling quicker aircraft turnaround. According to Jeff Atkinson, director of military programs at Goodrich's Aircraft Wheels and Brakes...

Read More »Honeywell Takes Air China to New Heights

Next-generation Avionics Suite to Help Air China Maximize Operating Efficiency and Safety SINGAPORE, Feb. 13, 2012 - Air China has extended its relationship with Honeywell (NYSE: HON) Aerospace with a range of agreements covering avionics and wheels and brakes. With an increasing number of aircraft filling the skies, pilots need critical flight-related data, including weather and traffic...

Read More »Portable Foundry Wheels reduce grinding time.

BlueFire(TM) zirconia aluminum portable foundry wheels are designed for foundries, welding shops, fabrication facilities, steel mills, and shipyards. Wheels are available in 4NZ, NZC, and NZAC for steel and dirty, scale-covered castings. An extended cutting capacity requires less operator time to remove material. Wheels are available in stock sizes from 4/3 x 2 x 5/8-11 to 6/4-13/16 x 2 x 5/8-11...

Read More »Alcoa Products on First Aluminum Petroleum Road Tanker in Indonesia

FUSINA, Italy & SURABAYA, Indonesia & NEW YORK - The first aluminum petroleum road tanker produced in Indonesia took to the highway recently made with Alcoa's heavy gauge aluminum shate product and rolling on Alcoa aluminum truck wheels. 5182 RoadTanker ShateG1, a combined sheet and plate product of a specific thickness, was developed by Alcoa Mill Products Europe for road tankers that transport...

Read More »

Additions to Weiler's Bonded Abrasives Line

To expand their Vortec Pro bonded abrasives product line, Weiler Corporation has added 12 & 14 cutting wheels in aluminum oxide and silicon carbide grains for general purpose cutting on metal and concrete applications. Weiler has also added 1 and 20mm arbors in the line. Vortec Pro bonded abrasive products are specifically designed for general purpose grinding and cutting applications on steel,...

Read More »

Simple Connection � MGB with EtherNet/IP

The new MGB with EtherNet/IP is a leap forward in access door safety. Designed for easy installation, flawless performance, and long service life, it is engineered with robust features and cutting-edge technology that places it firmly at the leading edge of the door safety device industry. To learn all about the benefits of the Euchner MGB, see our video.

Read More »