Model 2175B Track Cutter is Made from High Carbon Steel with a Non-Glare Finish

Equipped with cushioned Xuro-Rubber™ hand grips and a Light Touch™ return spring. Features Micro-Shear® blade that bypass cutting action which leaves clean square cuts . Used in HO, N and Z (code 100) scale modeling applications.

Read More »

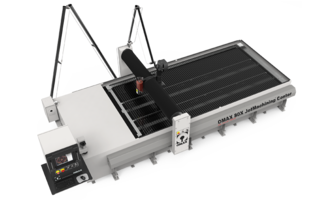

OMAX-® to Showcase Full Range of Waterjets at FABTECH 2019

KENT, Wash., July 24, 2019 – At FABTECH 2019, OMAX® Corporation will demonstrate the power of abrasive waterjets on four different machine models. Show attendees can explore each of the OMAX product lines to find out which waterjet is right for their particular applications. In booth A5731 at McCormick Place, Chicago, November 11-14, OMAX will showcase an OMAX 80X with a Tilt-A-Jet, a MAXIEM...

Read More »

New M4791 Routing Cutter from Walter Can be Used in Lathes and Machining Centers

Offered in diameters 0.75 in., 1.00 in., 1.25 in. and 1.50 in. with Weldon shanks for secure clamping. Capable of plunging in solid material and producing true flat bottom. Available in insert geometries of A57, D51, D57, F57 and G88.

Read More »

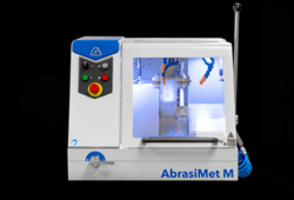

Buehler Releases AbrasiMet M bench-top Cutter for Metals and Other Tough Materials

Contains a manual saw with a powerful 5.5 hp (4kW) motor and can accommodate 10”[254mm] to 12”[305mm] optimized blades. Designed with 30-gallon recirculation tank along with nested tank and filtration screen. Offered with Bright LED light strips to increase visibility of samples.

Read More »

Tips for Managing Dangerous Dust in Manufacturing Facilities

This eBook covers important considerations when creating a dust management plan for your facility. For more information, download now.

Read More »OMAX to Tout Engineering Benefits of Abrasive Waterjet Technology at IMTS

KENT, Wash.Ã- – OMAX Corporation will highlight how the company’s abrasive waterjet technology is engineered to provide successful cutting solutions to the manufacturing industry at IMTS 2016. OMAX will have live cutting demonstrations in booth N-6228 to showcase how quickly their JetMachining Centers produce high precision parts from virtually any material. Visitors can watch 3D and...

Read More »

Five-Axis Fiber Laser System machines 3D parts.

Used to cut 3D formed or shaped parts, LT-FREE is capable of cutting, drilling, punching, and milling. Part does not move during operation; laser head's freedom of movement ensures flexibility and accuracy.Ã- Along with powers up to 5 kW, standard features includeÃ- 59 x 39 in. table; respective x/y/z axis strokes ofÃ- 116,Ã- 37, and 29 in.; and software used to create part...

Read More »

Pneumatic Saw precisely trims concrete pilings.

Featuring 14 in.Ã- fiberglass reinforced bladeÃ- withÃ- 5 in.Ã- cutting depth, MILLHOGÃ-® Air Powered Saw mounts ontoÃ- WrapTrackÃ-® SystemÃ- that clamps around 6–60 in.Ã- dia pile using stainless steel bands. Trolley mounts onto track and supports saw as it smoothly glides around on V-grooved, stainless steel wheels, and operator score cuts around piling to...

Read More »Ultrasonic Tool Head cuts composite and gasket materials.

Available for static table and conveyor systems, Ultrasonic tool head operates at 20,000 Hz (20,000 oscillations/sec)Ã- and is designed for cutting adhesive-backed, composite, or gasket type materials. Ultrasonic technology reduces blade gumming and friction between material and blade. While ultrasonic spindle has 3 in. stroke and is available with 30Ã-

Read More »

AXYZ International to Exhibit at ISA Sign Expo 2016

BURLINGTON, Ontario - AXYZ International, a global CNC router and knife cutting systems manufacturer, will be exhibiting specially selected products and technologies at ISA Sign Expo 2016 on April 20-23 at the Orange County Convention Center in Orlando, Florida. Customers attending the Expo can learn about new hardware and software technologies, investigate new methods of sign and graphics...

Read More »

Foamlinx Collaborates with Bay Area Recycling Company to Provide Custom Foam Recycling Services

Foamlinx LLC, a Silicon Valley based company, manufacturer of CNC foam cutting machinery is expanding its business to include custom foam recycling programs and services. The company has teamed up with foamrecycle.org, an environmentally green recycling company to offer pick up of foam scrap from local businesses, foam drop off and storage as well as foam recycling equipment rental. Full...

Read More »

Aerzen USA Process Gas Blower and Compressor Installations Worldwide

Aerzen is firmly established as a global leader in compressed air, gas, and vacuum solutions. Our reputation as an industry leader is built on consistently delivering innovative products that are at the cutting edge of technology. To learn about the industries finest blowers and oil-free and oil-injected screw compressors, see our video.

Read More »