Wheelabrator Rocker Barrel Machine: Providing High-Performance Continuous Cleaning

Burlington, ON - (January 27, 2009) - The WheelabratorÃ-® Continuous Rocker Barrel machine is designed for high-performance in-line cleaning of castings and forged parts. To satisfy production requirements ranging from less than 5 tons/hr to over 25 tons/hr, a variety of machine sizes are available with blast capacities selected to match the specific cleaning requirements. In December 2002,...

Read More »General Kinematics Introduces New Line of Rotary and Vibratory Drums

June 1, 2007 -- General Kinematics, Crystal Lake, IL, has announced the release of the DUCTA-SERIES(TM) line of rotary equipment, designed for ductile foundry operations, as well as new products in their VIBRA-SERIES(TM) line of vibratory foundry drums. The DUCTA-SERIES is comprised of the DUCTA-SPRUEÃ-® rotary sprue drum, the DUCTA-SCREENÃ-® rotary shakeout, and the DUCTA-CLEANÃ-®...

Read More »

Abrasive Blast Cleaner processes small parts.

WheelabratorÃ-® Barrel Blaster consist of 13Ã-½ in. diameter, 12 bladed wheel unit, powered by 15 hp, 3,600 rpm, NEMA T-frame, direct mounted motor. Barrel is 32 in. diameter and 37 in. deep, providing 3 ftÃ-³ tumbling capacity for up to 600 lb. Adjustable, pneumatically-operated butterfly valve allows for positive media flow control. System provides contaminant removal, peening, and...

Read More »

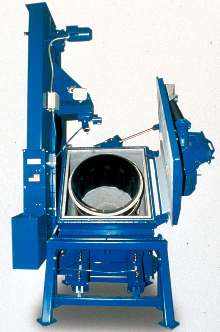

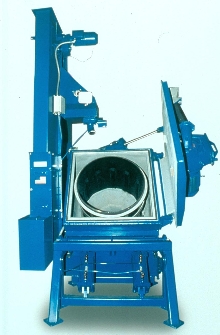

Tumbler enables processing of small parts.

Barrel Blaster allows parts to tumble uniformly in abrasive blast for cleaning and surface preparation. It consists of one 13 in. dia, 8-bladed wheel unit, powered by one 15 hp, 3600 rpm, NEMA T-frame, direct mounted motor. Its 32 in. dia barrel is 37 in. deep, providing three cubic feet tumbling capacity for up to 600 lbs. Single slide gate and pneumatically operated butterfly valve allow for...

Read More »Choosing the Right Load Ring for Your Needs

A Temper® Load Ring, also known as a Constant Force Adjustable Spacer, is a precision ring designed to perform as a predictable constant force element. It is fabricated from ductile, high strength stainless alloys.

Read More »

Blaster cleans castings and forgings.

Super III Tumblast(TM) uses 15 in. bi-directional wheel with patented curved blades to provide batch cleaning of castings, forgings, and other metal working pieces. Its 14 cu ft work capacity makes it suitable for scale, rust, sand, and contaminant removal; preparing surfaces for coating, grinding or machining; and deflashing, deburring, and shot peening. Abrasive recycling system reclaims and...

Read More »

Do You Have Unique Lifting Needs?

EZRig Cranes offers lifting solutions that are engineered for robust performance, providing the ultimate in portability. Designed for real-world lifting needs, our products are small and light with options and features that make them ideal for a broad range of applications. See our video to learn how an EZRig Crane can simplify your lifting requirements.

Read More »