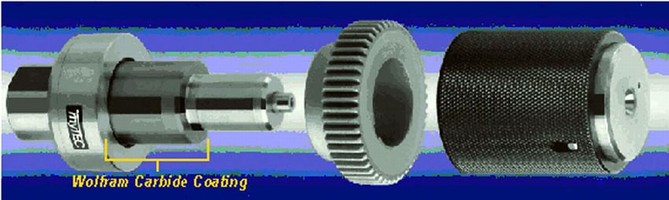

New Superior Wolfram Carbide Coatings

Mytec, a world leader in the manufacturing of fully braised, rupture proof construction hydraulic expansion clamping tooling, is pleased to announce the usage of Wolfram carbide coatings for their chucks and arbors. The advantages this coating brings are: o extreme holding power with a minimum amount of expansion. o sleeve hardness of 72-Rockwell to greatly decrease wear. o coating can be applied...

Read More »

Expansion Arbors help grind gears.

FORTIS arbors clamp work pieces or tools for gear grinding and hobb sharpening. High inner pressure when actuated stretches steel concentrically, providing constant clamping and vibration dampening. Total indicator run out is less than 0.00012 in. Concentricity of arbors is maintained within 0.005 mm between OD and ID. Arbors are sealed against contamination, allowing them to be used in machining...

Read More »

3 Formulation Methods to Reduce Lean Giveaway for Processed Meat

Download this white paper, and learn about three methods that can help you improve your bottom line and yield by reducing lean tissue giveaway.

Read More »

ISO-Certified Plastic Injection Molding from Rodon

The Rodon Group is a proven leader in high-volume, close tolerance injection molding. We offer globally competitive, innovative manufacturing solutions for a broad range of industries. Check out our video to learn more.

Read More »