Bassett Increases CNC Machining Capacities with New State of the Art Machines

Bassett is proud to announce the addition of VF4SS and VF11 CNC machining centers to its arsenal of existingÃ- CNC machines. With the addition of these machines, Bassett has increased its capacity in both size and production volumeÃ- with the ability to bring your most complex machined parts to full production quickly.Ã- Bassett has the know-how and equipment to provide quality...

Read More »DMI Event to Highlight Mazak Innovations that Boost Job Shop Efficiency

FLORENCE, Ky.,Ã- – Mazak distributor Dependable Machine Inc. (DMI) will host an open house at its new technology center in Hayden, Idaho, May 10-12 from 10:00 a.m. – 4:00 p.m. (PDT). The event will feature Mazak technologies that simplify part production processes as well as enhance shop floor productivity and versatility. A must-see for attendees will be Mazak’s MAZATROL SmoothX CNC....

Read More »

Machining Centers feature diagnostic communication system.

Standard on Cincinnati and Giddings & Lewis machine tools and composite systems, Diagnostic Communication System allows machine operators to connect with company experts via secure CNC screen sharing to diagnose and overcome stoppages within minutes. System is also available as upgrade for installed machines with PC-based HMI on Fanuc, Siemens, and Heidenhain controls. Enabling software,...

Read More »

Mazak Presents its HYBRID Approach to Additive Manufacturing at RAPID

Company combines additive and subtractive processes with multi-tasking part processing FLORENCE, Ky.Ã- - Mazak firmly established its position at the forefront of additive manufacturing with the development of HYBRID Multi-Tasking technology, which the company will present at this year’s RAPID Conference and Expo. The event takes place at the Orange County Convention Center in Orlando,...

Read More »

Steel Wire Selection Guide for Various Applications

Download this eBook to learn about how steel wire products can be used for a variety of applications.

Read More »

CNC Machining Services offer expanded capabilities, capacities.

Machining services, made possible via Okuma LB45III-C / 2000 CNC machine, cover parts up to 26 in.Ã- dia x 80 in. long. Its long, horizontal bed capacity is suited for creating large parts, such as long shafts required by aerospace industry, or long liners required for oilÃ- and gas industry.

Read More »

Nanotech Demonstrates Most Flexible Diamond Turning System

During SPIE Photonics West 2014 in San Francisco, Nanotech will demonstrate what has become their true flagship machining system. The Nanotech 350FG is the most diverse ultra-precision machine available. Starting with a minimum of three ultra- precision axes, it is easily expandable to five axes via optional B & C rotary axes. Typical applications for this machine include axisymmetric machining...

Read More »

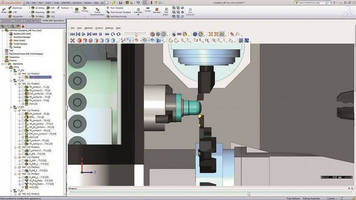

SolidCAM to Showcase the Power of SolidCAM with iMachining at SolidWorks World 2014.

Attendees will be able to see demonstrations of how they can save 70% or more using SolidCAM with patented iMachining, seamlessly integrated in SolidWorks. Newtown, PAÃ- – SolidCAM, the leader in integrated CAM, provides today the most complete and powerful integrated CAM solution for SolidWorks. SolidCAM will demonstrate the power of the integrated SolidWorks + SolidCAM CAD/CAM solution,...

Read More »Astro Machine Works Introduces Our New EDM Capabilities

What better way to start the year than with new electrical discharge machining services (EDM) to add to our already long list of capabilities? How else to bolster our EDM offerings than adding the newest and latest in machines? With the introduction of the Sodick AQ5371 Wire EDM machine, Astro Machine is doing just that. As EDM work has only been a service we have worked with for the past twelve...

Read More »

Machine Tool Runoff Cutting Titanium Confirms Advantages of 'Ultimate Tuned System'

When it comes to sourcing capital equipment for machining specialty materials, many organizations would do well to remember the 10-speed bicycle analogy. People shop and buy a 10-speed bike for recreational or workout goals, but when riding rarely go beyond two or three of the most comfortable gears. Tour de France riders and other finely tuned athletes both size and operate all their components...

Read More »

Hardinge Supplies a Precision Grip for Medical Component Manufacturing

Hardinge, well known in the industry for their SUPER-PRECISIONÃ-® products, provides gripping solutions for machining small diameter parts for medical component manufacturing. One category of products includes Swiss-type headstock collets, pickoff collets, carbide guide bushings, bar loader collets and custom manufactured solutions for Swiss turning. Their Swiss-type collets are finish ground...

Read More »

Innovative Dampney Coating Systems Suit Even the Most Specialized Applications

Dampney's high performance coating systems provide protection against extreme weather, chemicals, and corrosive environments for atmospheric, immersion, and underground applications. Check out the video to learn more.

Read More »