New 2nd Generation of UP Modular Boards Feature Intel Apollo Lake Processors

Configured with up to 8 GB of onboard memory and up to 128 GB onboard eMMC storage. Features USB 3.0, DP and USB OTG connections as well as support for wireless and Bluetooth connectivity. Supports up to four PCI express lanes.

Read More »

New SMART+ Feature Interactive HMI Touch Screen Control Panel

HMI panels are unaffected by heat or cold and operate across a diverse range of industrial environments. Operates through leather work gloves or heavy-duty welding gloves. Sleek and modern panels offer real-time feedback.

Read More »

New ASDM-S-KBU Features 7th Generation Intel Core Processors

Offers unparalleled computing power for its compact size. Features performance to push smart displays to edge. Suitable for context sensing in virtual dressing rooms, power smart retail and smart vending solutions.

Read More »

New ODVA Conformant Drives and Motors Perform Positioning, Velocity and Motion Control Tasks

SV200 Digital Servo Drives provides advanced performance and auto-tuning with multiple control options. ST Stepper Drives includes stall detection, stall prevention, microstep emulation and anti-resonance. StepServo™ Integrated Motors features high-resolution incremental encoders and closed-loop servo firmware.

Read More »

Grips and Handles - Providing a Strong and Comfortable Grip

To learn more about the different types of Grip and Handle options available or which to select for your specific application, download our product guide.

Read More »

New 88 PX Series NVMe ArmourDrive SSDs Operates at -40 to +85 degrees Celsius

Available in 2242 form factor (64 GB, 128 GB, 256 GB, 512 GB) and 2280 form factor (240 GB, 480 GB, 960 GB, 1.92 TB). Supports AES-256 / TCG OPAL encryption (2280) and secure erase. Ideal for space-constrained, broadcasting, industrial gaming, factory automation, networking and security applications.

Read More »

New XC2 PWM Digital Drive Includes Single-axis Position Synchronized Output

Controls brushless DC, brush DC, voice coil or stepper motors at up to 100 VDC operating voltage and 10 A peak current capability. Accepts square-wave encoder feedback at rates of up to 40 million counts-per-second. Compatible with the automation 3200 motion platform utilizing the HyperWire® motion bus.

Read More »

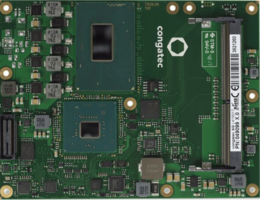

Congatec Announced COM Express Type 6 Modules Featuring Intel Embedded Processor Technology

Available in Intel® Xeon®, three Intel® Core™, two Intel®Celeron® and one Intel® Pentium® processors. Applications include classic high-end medical imaging systems, HMIs, high-end gaming, infotainment and digital signage systems. Provide embedded computing performance with integrated high-performance processor graphics.

Read More »

New Mobile360 M820 In-vehicle System Measures 240mm x 53mm x 180mm

Supports 9 FAKRA input connectors, 2 USB 3.0 ports and 1 Micro USB 2.0 port, DIO and COM ports, 1 HDMI 2.0 port and CAN bus port. Powers a comprehensive software suite that supports ADAS, SVS, DMS, PAS and DMOD applications. Capable of stable operation at temperatures ranging from -20°C to 70°C.

Read More »

New BIO Controllers & Meters Resist to In-line Water Contamination

Features ultrasharp color display which provides at a glance understanding of user processes status. Includes high-speed EtherCAT or EtherNet/IP interfaces option to meet or exceed pharma 4.0 requirements. Ideal for monoclonal antibody production, vaccine production, insulin production and organ/tissue maintenance.

Read More »

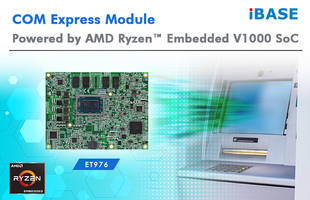

New ET976 Computer-on-Modules Express Module Comes with DDR4 RAM

Powered by AMD Ryzen™ and Embedded with V1000 SoCs processors including V120B, V1605B, and V1807B along with Radeon Vega 3 graphics. Supports 2x independent displays, DisplayPort/ DVI-D/ LVDS or eDP via carrier board. Equipped with 4x USB 3.1, 8x USB 2.0, 2x SATA III and supports TPM (2.0).

Read More »

Simple Connection � MGB with EtherNet/IP

The new MGB with EtherNet/IP is a leap forward in access door safety. Designed for easy installation, flawless performance, and long service life, it is engineered with robust features and cutting-edge technology that places it firmly at the leading edge of the door safety device industry. To learn all about the benefits of the Euchner MGB, see our video.

Read More »