Weld Purge Systems weld stainless steel tube and pipe joints.

Press Release Summary:

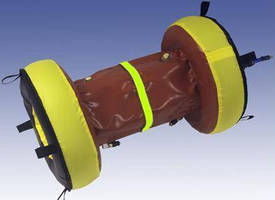

Developed for high-speed welding of Liquid Natural Gas pipe work, Argweld® Quick Purge(TM) Systems incorporate argon purging valve arrangement that is optimized for all different pipe diameters. Original adjustment system is eliminated so trial setting is not necessary. To help welders identify location of purge systems below weld joint where it is normally dark, high-visibility Glo Strip has been incorporated centrally between dams, ensuring accurate positioning.

Original Press Release:

Weld Purge Global Standard Undergoes Major Makeover

In response to customer requirements and advances in technology Huntingdon Fusion Techniques' international best sellers, the Argweld® Quick Purge(TM) Systems have been improved significantly.

A new argon purging valve arrangement has been incorporated which is optimised for all different pipe diameters. The old adjustment system has been eliminated, so trial setting is no longer necessary thus saving more time on each weld.

To help welders identify the location of the purge systems below the weld joint, where it is normally dark, a high visibility 'Glo Strip' has been incorporated centrally between the dams. This ensures accuracy of positioning.

Major international pipework fabricators, including Bechtel Corporation and Chicago Bridge and Iron Company, have applauded the huge cost and time benefits accruing from the use of Quick Purge.

Recognising the technical innovation involved in design and manufacture and the popularity of the systems with welding engineers internationally, Huntingdon Fusion Techniques now has world wide patent protection on the product range.