Vision System provides high accuracy and TIR.

Press Release Summary:

STP-34 EzVision delivers .0003 in. accuracy at 12 in., with display resolution of .0001 in. Thermo-balanced and artificially aged pearlitic cast-iron structures ensure that equipment is isostatic and will not deform over time or temperature change. Digital tool sensing removes potential for error inherent in manual systems. System measures tool diameter up to 12 in. and tool length up to 16 in. It offers data memory for 250 zero set points and 1,000 nominal tool dimensions.

Original Press Release:

New STP 34 EzVision System Delivers Unmatched Accuracy and T.I.R.

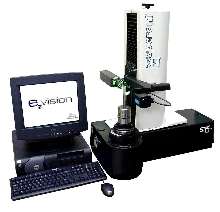

ELK GROVE VILLAGE, IL-A new STP-34 EzVision system created for KPT/Speroni introductory level presetter users delivers unmatched accuracy and T.I.R. (maximum .0003"/0.0076mm at 12"/300mm), with display resolution of .001mm (.0001") for added detail, KPT/Kaiser Precision Tooling Inc. announced.

The EzVision system's quick gage capability will measure any tool. It provides management and display of tooling and cutting edges on the same monitor as the Speroni PC-based EzVision control. The system features one micron Heidenhein glass scales. Its thermo-balanced and artificially aged pearlitic cast iron structures ensure that the equipment is fully isostatic and will not deform or distort over time or temperature change - a fundamental requirement in providing long-term linear accuracy and repeatability.

Digital tool sensing removes potential for error inherent in manual measurement systems that rely on the operator's sighting and judgment to focus and align tools within the optics of a tool presetter. It assures reproducibility of precision settings, no matter which operator uses the instrument.

After inserting the tooling in the video STP-34 EzVision's spindle, the operator sets maximum diameter by reading simple digital values and following color codes on a personal computer monitor. Obtaining measurement values is as easy as aligning the tool to the cross hairs or using one of the custom measurement macros. The computer replaces the digital readout used on many competing presetters, so the operator does not have to learn to operate two sets of controls - both digital readout and computer monitor.

"Digital tool sensing is especially recommended for operations where it is necessary to hold tighter tolerances. It provides resolution down to 10 millionths of an inch on the diameter. Also, it provides consistent readings that will not vary with each individual operator's judgment," says Douglas Sumner, KPT/Kaiser's National Product Manager, Tool Measuring & Presetting Systems.

The EzVision control features a centering indicator box that is ideal for presetting angular cuts, as in chamfering. It may also be used to calculate nose radii and angles.

Episcopy is one of the STP-34's most popular optional features. The episcopy option provides an easy way to detect defects or deformities by illuminating and magnifying the cutting edge.

The STP-34 EzVision measures tool diameter up to 12" (304.8mm) and tool length up to 16" (404.4mm) and delivers all the benefits of the manual model, including repeatability to plus or minus 1.5 tenths (.00015"/0.0038mm), data memory for at least 250 zero set points and 1,000 nominal tool dimensions.

The STP 34 EzVision shares many features with other versions of the popular KPT/Speroni STP-34. Its spindle has a gage point reference that makes it possible to perform calibrations without a test bar. It features fast manual axis movement (singular or simultaneous) provided by an ergonomic handle for an extremely smooth motion along the Z and X-axis, with a simultaneous locking mechanism. Fine adjustments are provided throughout the travel range.

The Speroni PC-based EzVision control (Windows XP(TM) operating system) comes complete with VGA color monitor, mouse and keyboard. The PC (Dell with three-year, in customer's shop warranty) is supplied with CD ROM, 3.5' floppy drive, and a hard disk for the storage of at least 1,000 tools and 250 zero points.

Options available for the STP-34 EzVision system include a spindle disc brake system, an alphanumeric label printing kit, a spindle index for lathe tools and post processor software that sends offsets directly to the machining center.

Speroni S.p.A., Pavia, Italy, designs and manufactures high precision tool presetting and measurement systems, integrated systems for tool management, test robots and vision systems. Speroni believes feedback from the market and its product users are the most important factors in its success. The company has more than 4,000 installations worldwide.

KPT/Kaiser Precision Tooling Inc., based in the Chicago suburb of Elk Grove Village, is the U.S. subsidiary of Heinz Kaiser, Ltd., Rümlang, Switzerland, a worldwide developer and manufacturer of precision boring tools of unmatched quality for thousands of applications in metalworking. KPT/Kaiser provides a comprehensive line of setup reduction tools, tool measurement and presetting systems, and KPT/Unilock workholding systems.

For more information about the new STP-34 EzVision system, KPT/Speroni presetting and tool management systems or other KPT/Kaiser tooling solutions, contact KPT/Kaiser Precision Tooling Inc. at 641 Fargo Avenue, Elk Grove Village, IL 60007, telephone 847/228-7660, fax 847/228-0881, e-mail kptkaiser@kptkaiser.com, web kptkaiser.com or contact the KPT/Kaiser tool distributor in your area.