Vehicle Impact Simulator has compact, automated design.

Share:

Press Release Summary:

Compact Impact Simulator features servo valve and hydraulically powered ram to accelerate track-guided, 1,000 kg capacity test sled to up to 65 km/hr. Max gas pressure is 350 bar and, after crash pulse, hydraulic system requires about 100 sec to build up pressure in cylinder again. Measuring 18 x 2.2 x 1.5 m, product integrates accelerometer, 8-channel M=BUS PRO DAQ system, and Crashsoft reference control software. System tests safety belts, airbags, seats, or roof carriers.

Original Press Release:

Next Generation Test System Engineering: The Compact Impact Simulator from MESSRING

Compact servo-hydraulic sled system / space-saving and ideal for retrofitting / highly precise M=BUS data acquisition system integrated / fully automatic test flow

Munich – The Compact Impact Simulator (CIS) from MESSRING Systembau GmbH of Munich opens up new possibilities for automotive OEMs, suppliers and governmental institutions: you can use this system to test vehicle components such as safety belts, airbags, seats or roof carriers effectively, precisely and reproducibly. It does all of this without requiring a complete crash test facility and within a relatively small floor space.

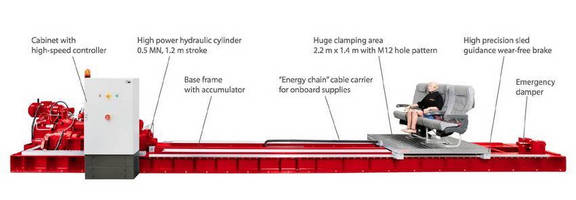

The CIS is an exceptionally compact sled system that utilizes a servo valve and a hydraulically powered ram to accelerate a test sled to speeds of up to 65 km/h (40mph). The sled is guided in a track system and features controlled braking by a wear-free brake.

The CIS can be used to smoothly perform many different standardized tests, such as the Whiplash Test (rear crash) in conformance to EuroNCAP regulations and NHTSA regulations in America.

Another big advantage of the CIS is that it integrates the M=BUS data acquisition system; this measuring module is mounted directly to the acceleration sled and routes highly precise results to the control software for evaluation. CIS instrumentation consists of an accelerometer and the proven 8-channel M=BUS PRO data acquisition system, which logs even the slightest of movements. Along with the precise data acquisition system, Crashsoft is also included – the reference control software for test and data acquisition systems. It clearly organizes the many different system settings and presents results to the user on a PC in a simple and easy-to-comprehend way.

The overall system operates fully automatically and can be independently controlled by just one person. Full automation of the CIS enables a short time span between two tests of under ten minutes, which guarantees a high testing frequency for all operators. The overall system boasts considerable performance data despite its compact system dimensions.

The footprint required for the entire system is just 18 m x 2.2 m x 1.5 m. These small dimensions make it possible to use the simulator in many different test spaces, and it even fits in areas, which could not be used to perform sled tests due to insufficient space. This characteristic makes the CIS ideal for all users who want to retrofit an existing system and do not wish to build a separate hall for the test system or are unable to do so. Another advantage: The CIS can be installed much more quickly and is far less cost-intensive than a new complete crash system or classic sled system.

Similar to the type of construction used in high-end vehicles or aircraft, the sleds from MESSRING are made of high-quality, extremely lightweight carbon fiber reinforced materials to attain the highest possible speeds over a short acceleration distance. Its maximum speed is 65 km/h. The sled of the simulator can handle maximum loads of up to 1,000 kg. Besides legally prescribed standard pulses, very dynamic vehicle pulses can also be implemented.

A skillfully designed control valve regulates the ram, which accelerates the sled on the rail system. At a maximum gas pressure of 350 bar, the user can trigger the ram at the press of a button. After the crash pulse, the hydraulic system only requires about 100 seconds to build up this pressure in the cylinder all over again.

Robert Weber, CEO of MESSRING, is proud of the new development: "One can certainly state that the CIS is a remarkable advanced development in the field of sled systems. No other product on the market matches its compactness combined with these technical benchmarks. We have invested our hearts and souls into its development and are proud of the many in-house developments that we were able to integrate in the system." MESSRING offers the CIS as a turnkey crash test system. Not only are the entire M=BUS data acquisition system and crash software included; the system is also fully compatible with the recently introduced M=LIGHT LED lighting system which can be integrated as well. The first operationally ready CIS has already been delivered to a well-known test center in northern Germany.

Technical data:

Nominal force: 0.5 MN

Maximum speed: 65 km/h

Overall acceleration: 45 G

Typical payload: 400 kg

Maximum payload: 1,000 kg

Maximum stroke: 1.2 m

Frequency: >140 Hz

Maximum jerk: >15 G/ms

Dimensions of sled platform: 2.2 m x 1.4 m

Time span between two tests: <10 min

Required floor space: 18 m x 2.2 m x 1.5 m

Required power input: <40 kVA

About MESSRING

MESSRING Systembau GmbH, headquartered in Munich, is the world's leading manufacturer of crash-test facilities and its components. The medium-sized company designs and builds turnkey test systems for customers in all relevant markets and on nearly all continents. To date, MESSRING has implemented over 90 large crash-test systems for automotive OEMs, insurance companies, and governmental facilities – more than any other company. The global market leader continues to impress its customers with innovative developments and revolutionary new solutions, whether in system design, measurement equipment, or the documentation and recording of individual tests.

For additional information, please visit www.messring.de .

Press Contact:

Enno Hennrichs

Talk of Town. Wächter Wächter

Lindwurmstrasse 88, 80337 Munich, Germany

Phone +49-89-747-242 ext. 39, fax ext. 60

e.hennrichs@waechter-waechter.de

www.talkoftown.de

www.twitter.com/talkoftown.de

www.facebook.com/talkoftownpr