Tooling System punches accurately.

Press Release Summary:

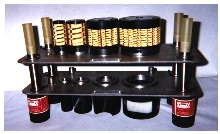

XimmiX(R) heavy-duty H-Series tooling can punch up to 0.250 in. thick mild steel with hole location accuracy of +/-0.005 in. or better. Tooling operates on bump-die principle, so no die set or ram attachment is required. It is suitable for square sheared blanks or strip stock and is adaptable to coil-fed applications. Components such as corner posts and tool holders can be reused as new jobs are added to system.

XimmiX(R) heavy-duty H-Series tooling can punch up to 0.250 in. thick mild steel with hole location accuracy of +/-0.005 in. or better. Tooling operates on bump-die principle, so no die set or ram attachment is required. It is suitable for square sheared blanks or strip stock and is adaptable to coil-fed applications. Components such as corner posts and tool holders can be reused as new jobs are added to system.Original Press Release:

S. B. Whistler & Sons, Inc. Introduces Heavy Duty Tooling System

Akron, NY, February 20, 2002- S. B. Whistler & Sons, Inc., a manufacturer of Modular Hard Die Systems for piercing and notching sheet metal, is pleased to announce it's latest tooling system, XimmiX(R) Heavy Duty H-Series tooling. XimmiX(R) H-Series tooling is designed to punch up to .250" thick mild steel and guarantees hole location accuracy of +/-.005 or better. XimmiX H-Series tooling operates on the "bump-die" principle, therefore no die set or ram attachment is required.

Like other modular Hard Die systems manufactured by Whistler, XimmiX H Series tooling reduces tool costs and eliminates the need for all-new tooling on every job. Capital components such as corner posts and tool holders are purchased with the initial order. As new jobs are added to the system, the capital components can be reused and amortized over many parts, resulting is increased savings, faster lead times and significantly reduced tool charges. The small tool footprint allows denser tool configurations than other flexible tool systems. Stampings are punched in fewer operations (hits). XimmiX H-Series tooling is ideal for square sheared blanks or strip stock and is adaptable to coil fed applications.